Absorption core and preparation method of absorption core

A technology for an absorbing core and a manufacturing method, which is applied in the fields of absorbing pads, medical science, clothing, etc., can solve the problems of hard spot phenomenon, blocking the mesh of the forming mesh belt, and increasing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

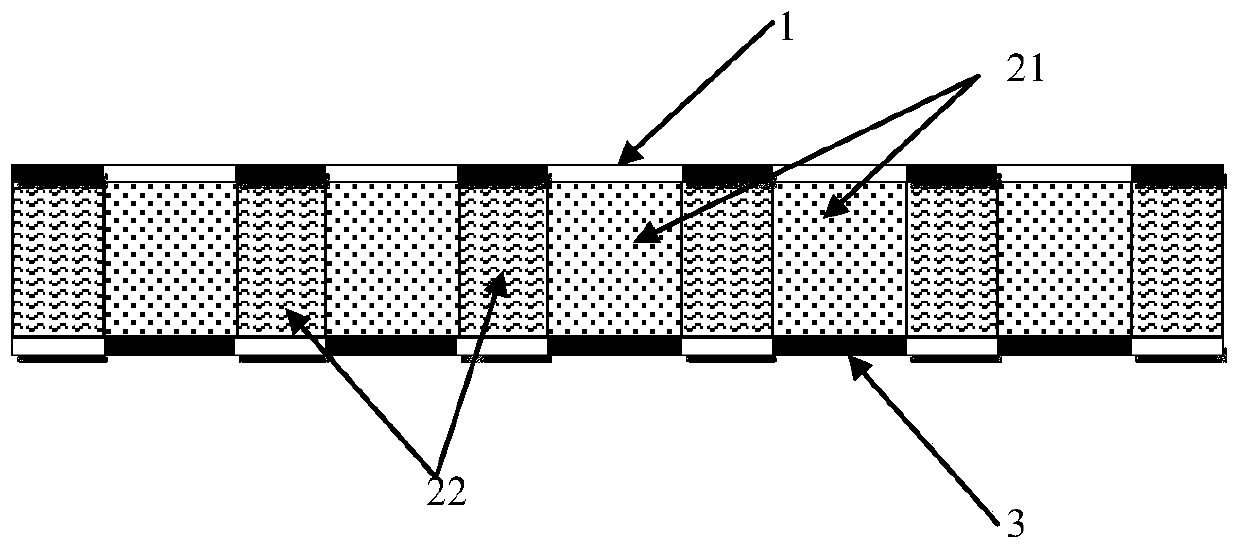

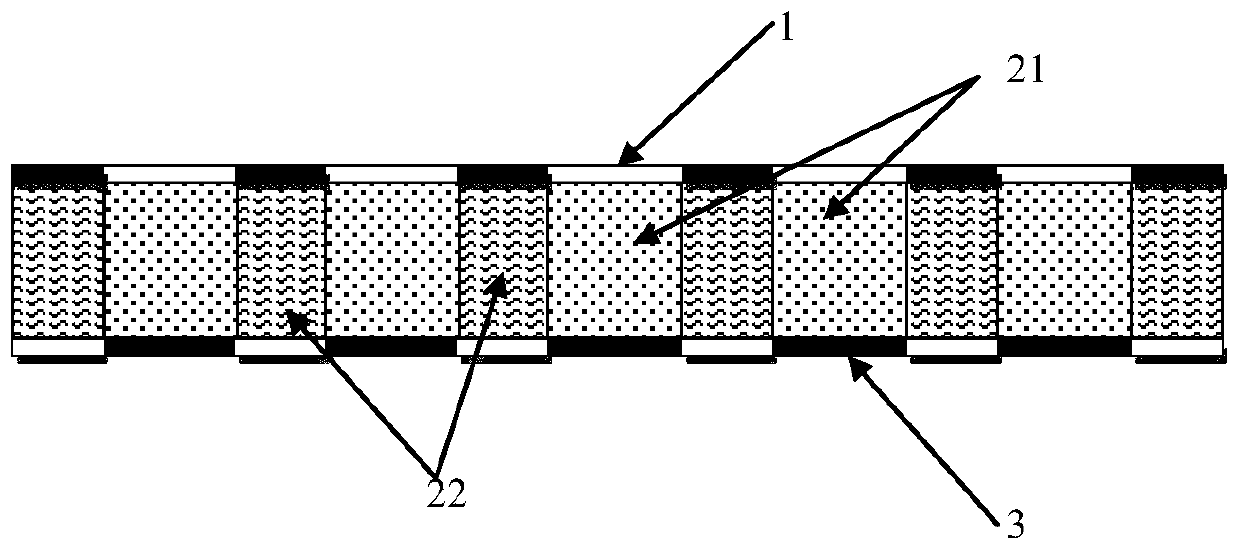

[0036] The upper layer of spunbonded nonwoven fabric 1 is alternately treated with hydrophilic and water repellent, and the width of hydrophilic ( figure 1 Middle black part) 4mm, water repellent width ( figure 1 Medium white part) 5mm;

[0037] The lower layer of spunlace non-woven fabric is also alternately treated with hydrophilic and water-repellent, and the water-repellent width ( figure 1 Medium white part) 4mm, hydrophilic width ( figure 1 Middle black part) 5mm.

[0038] A row of superabsorbent fibers 22 is arranged on the hydrophilic treatment part of the upper spunbonded non-woven fabric, and a row of superabsorbent resin 21 is arranged between two adjacent rows of superabsorbent fibers.

Embodiment 2

[0040] The upper layer of spunbonded nonwoven fabric 1 is alternately treated with hydrophilic and water repellent, and the width of hydrophilic ( figure 1 Middle black part) 5mm, water repellent width ( figure 1 Medium white part) 5mm;

[0041] The lower layer of spunlace non-woven fabric is also alternately treated with hydrophilic and water-repellent, and the water-repellent width ( figure 1 Medium white part) 5mm, hydrophilic width ( figure 1 Middle black part) 5mm.

[0042] A row of superabsorbent fibers 22 is arranged on the hydrophilic treatment part of the upper spunbonded non-woven fabric, and a row of superabsorbent resin 21 is arranged between two adjacent rows of superabsorbent fibers.

[0043] In this example, in the hydrophilic part of the upper non-woven fabric, the degree of hydrophilicity is weak in the middle and gradually increases toward both sides; the water-repellent part is strong in the middle and gradually weakens toward both sides.

Embodiment 3

[0045] 1) Prepare the upper layer

[0046] The upper layer of spunbonded nonwoven fabric 1 is alternately treated with hydrophilic and water repellent, and the width of hydrophilic ( figure 1 Middle black part) 4mm, water repellent width ( figure 1 Medium white part) 4mm;

[0047] Among them, in the hydrophilic part, the degree of hydrophilicity is weak in the middle and gradually increases toward both sides; the water-repellent part is strong in the middle and gradually weakens toward both sides.

[0048] 2) Prepare the lower layer

[0049] The lower layer of spunlace non-woven fabric 3 is also alternately treated with hydrophilic and water-repellent, and the water-repellent width ( figure 1 Medium white part) 3mm, hydrophilic width ( figure 1 Middle black part) 4mm.

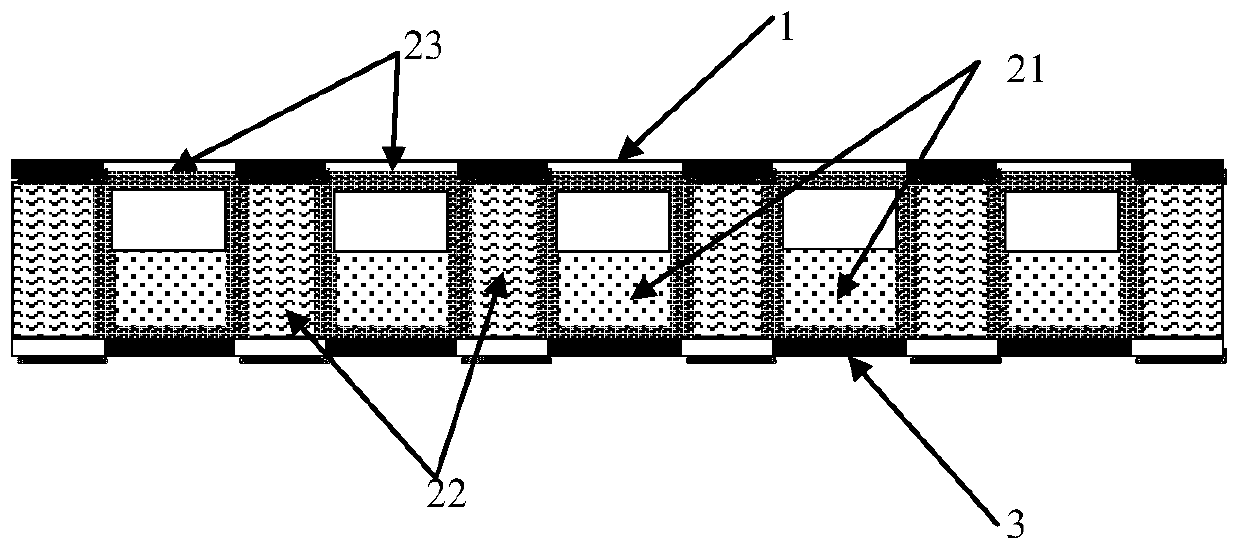

[0050] 3) Prepare the middle layer

[0051] Prepare hydrophilic hollow foam 23;

[0052] Close one end of the hydrophilic hollow foam;

[0053] The superabsorbent resin 21 is placed in the hydrophilic h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com