Ink for ink-jet printing of organic light-emitting layer, preparation method and applications thereof

An organic light-emitting layer, inkjet printing technology, applied in the application, ink, household appliances and other directions, to achieve the effect of large uniformity of film formation, simple preparation method and stable ink discharge state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides the preparation method of above-mentioned ink, it refers to following steps:

[0040] In step S1, the mixed host luminescent material, the doped phosphorescent luminescent material and the viscosity regulator are mixed and dispersed, and heated and stirred at 55° C. to 65° C. to obtain a mixed precursor.

[0041] Preferably, it also includes mixing, dispersing and thermally stirring the organic solvent to obtain a mixed precursor.

[0042] Generally speaking, it is preferable to use a frequency of about 99 kHz for ultrasonic dispersion, and the control time is 10 min to 20 min; and the thermal stirring time is controlled to 0.5 h to 1 h.

[0043] It is worth noting that in the above mixing and dispersing process, ultrasonic dispersion and thermal stirring can be carried out without the five raw materials being completely mixed. According to the properties of specific raw materials, all mixing and dispersing and thermal stirring or ste...

Embodiment 1

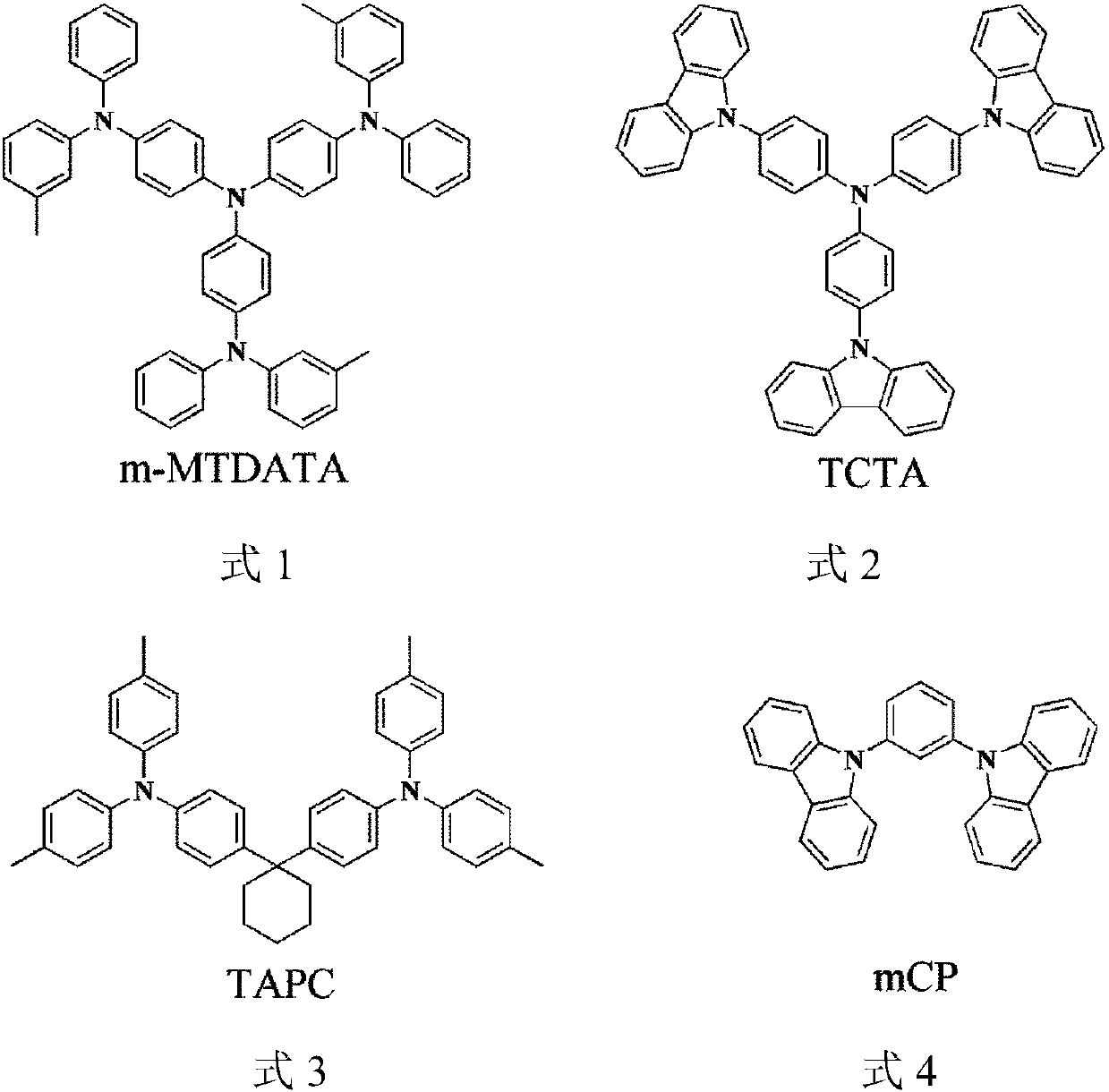

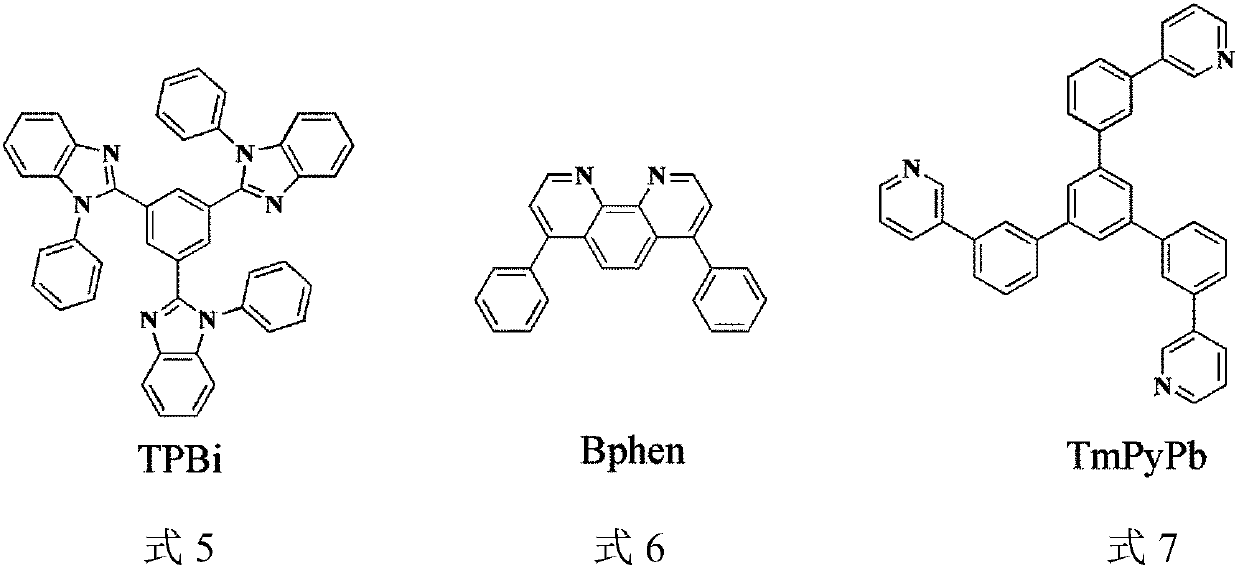

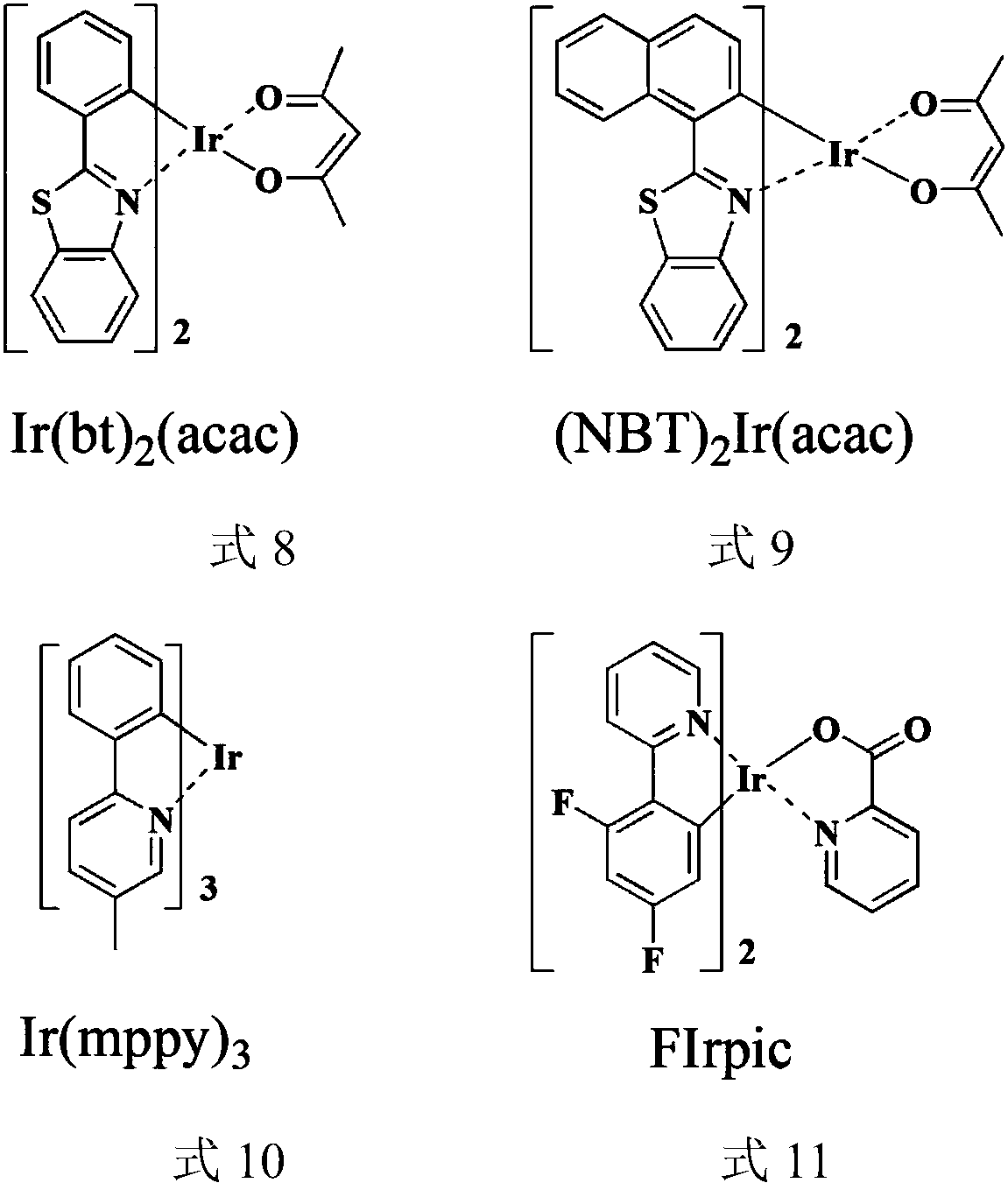

[0054] First, weigh 27mg m-MTDATA, 27mg TPBi and 6mg Ir(mppy) 3 Put it in a 4mL reagent bottle, measure 2mL of butyl benzoate and 0.4mL~0.5mL of toluene into the reagent bottle, first ultrasonicate at a frequency of 99kHz for 10min~15min to completely disperse the solute in the solvent, and then dissolve the solute at 55°C Heat and stir at ~65°C for 0.4h to 0.6h to make the solute (i.e. mixed host material m-MTDATA and TPBi and doped phosphorescent material Ir(mppy) 3 ) is completely dissolved to obtain a mixed precursor.

[0055] Then, the above-mentioned mixed precursor was filtered with a 0.2 μm filter head to obtain an ink.

[0056] In the obtained ink, its solid content is 24mg / mL~25mg / mL, the concentration of the mixed host material is 21.6mg / mL~22.5mg / mL, and the hole transport material m-MTDATA and the electron transport material TPBi The mass ratio is 1:1, doped with phosphorescent material Ir(mppy) 3 The doping ratio is 10% (that is, the total mass of the mixed ho...

Embodiment 2

[0060] First, weigh 150mg of MCP and place it in a 6mL reagent bottle A, measure 5mL of benzyl benzoate into the reagent bottle A, and sonicate at a frequency of 99kHz for 15min to 20min to obtain a clear solution A of 29mg / mL to 30mg / mL . Another weighed 150mg of Bphen was placed in a 6mL reagent bottle B, and 5mL of benzyl benzoate and 0.02mL of chlorobenzene were added to the reagent bottle B, and ultrasonicated at a frequency of 99kHz for 15min to 20min to obtain 29mg / mL to 30mg / mL Clarify solution B. Another weighed 60mg Ir(bt) 2 (acac) was placed in a 4mL reagent bottle C, 2mL benzyl benzoate and 0.02mL chlorobenzene were added to the reagent bottle C, and ultrasonication was performed at a frequency of 99kHz for 15min to 20min to obtain a clarification of 29mg / mL to 30mg / mL Solution C.

[0061] Again, measure solutions A, B and C in a volume ratio of 2:2:1 and place them in reagent bottle D, heat and stir at 55°C to 65°C for 0.5h to 1h; mix solutions A, B and C is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com