Camera-based keyboard automatic assembling device for practical training

An automatic assembly device and camera technology, applied in the direction of manipulators, assembly machines, educational tools, etc., can solve the problems of inability to realize the positioning and assembly of scattered components, unsuitable for complex assembly training, and inability to realize camera learning and operation, etc., to achieve improved Effects on cognitive and operational skills, improved clarity, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described now in conjunction with accompanying drawing.

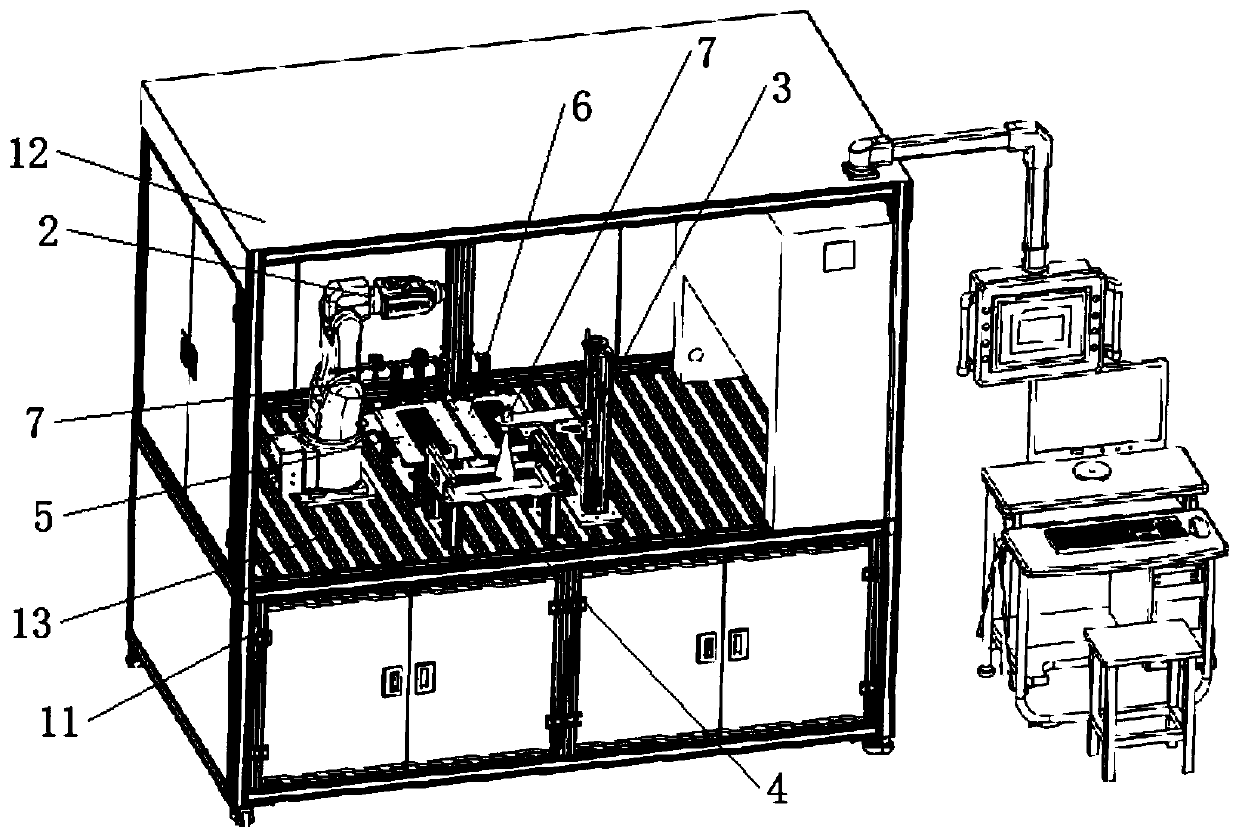

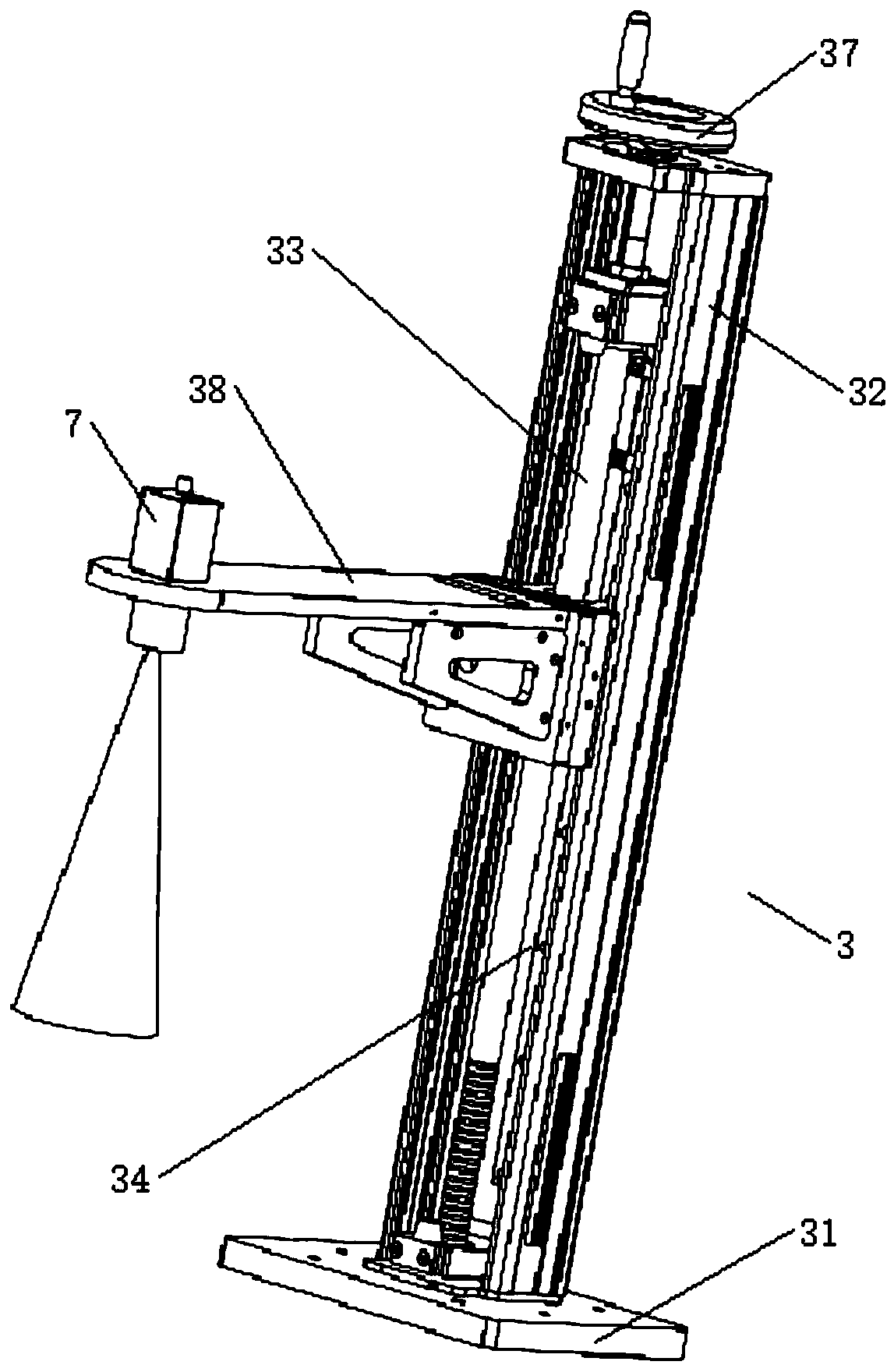

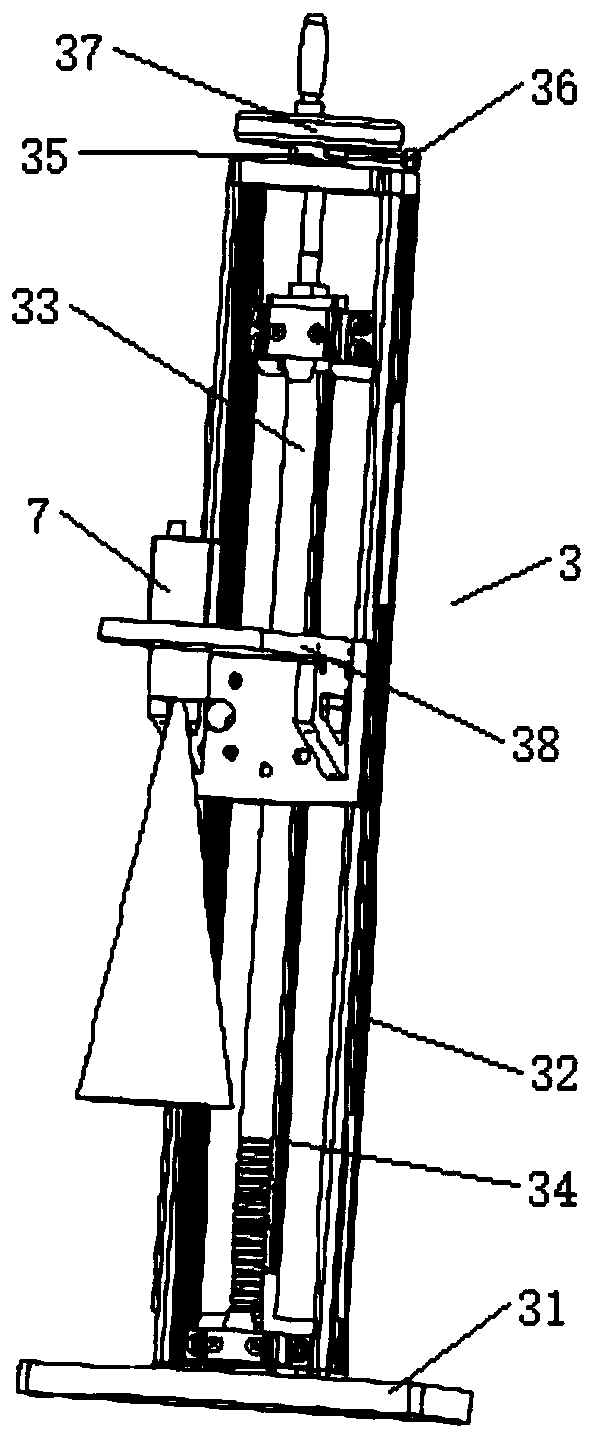

[0042] Such as Figure 1 to Figure 8 As shown, the automatic assembly device based on the camera keyboard for training includes a workbench 11, a mechanical arm 2, a camera 7 and a quick-change tool tray 81. There are no less than two quick-change tool trays 81, and the robotic arm 2 is installed on the workbench 11. On, also comprise camera frame 3, camera 7 is housed on camera frame 3; Button tray 4, button tray 4 is positioned at the below of camera 7, and a plurality of buttons 101 are placed on button tray 4; Keyboard 102; finished product tray 6, finished product tray 6 is used for placing assembled keyboard 102; vacuum suction cup 83, one end of vacuum suction cup 83 is equipped with quick-change tool tray 81; pneumatic gripper 84, quick-change tool is housed on pneumatic gripper 84 Disk 81; tool rack 7, vacuum sucker 83 and pneumatic gripper 84 are all movably insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com