Mining and separating method for riverway dredged materials

A technology of river dredging and separation method, which is applied in the field of river dredging and mining and separation of river dredging materials, which can solve problems such as low efficiency, secondary pollution, soft land, etc., and achieve simple screening steps, increase load-bearing capacity, and sand production Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for mining and separating river dredged materials, using river dredged materials as raw materials, comprising the following steps:

[0039] S01 Use a sand pump to extract raw materials from the river and transport them to the floating body through pipelines;

[0040] S02 separates the natural sand from the gravel through the vibrating screen, and transports the natural sand to the sand tank;

[0041] After S03 stones are sieved, they are divided into large stones with a particle size greater than 4cm and small stones with a particle size less than or equal to 4cm;

[0042] S04 Crushing large stones and small stones respectively, transporting them to the sand making machine to prepare sand, and then transporting the sand to the sand tank;

[0043] S05 transports the sand in the sand pool to the sand field with a sand pump.

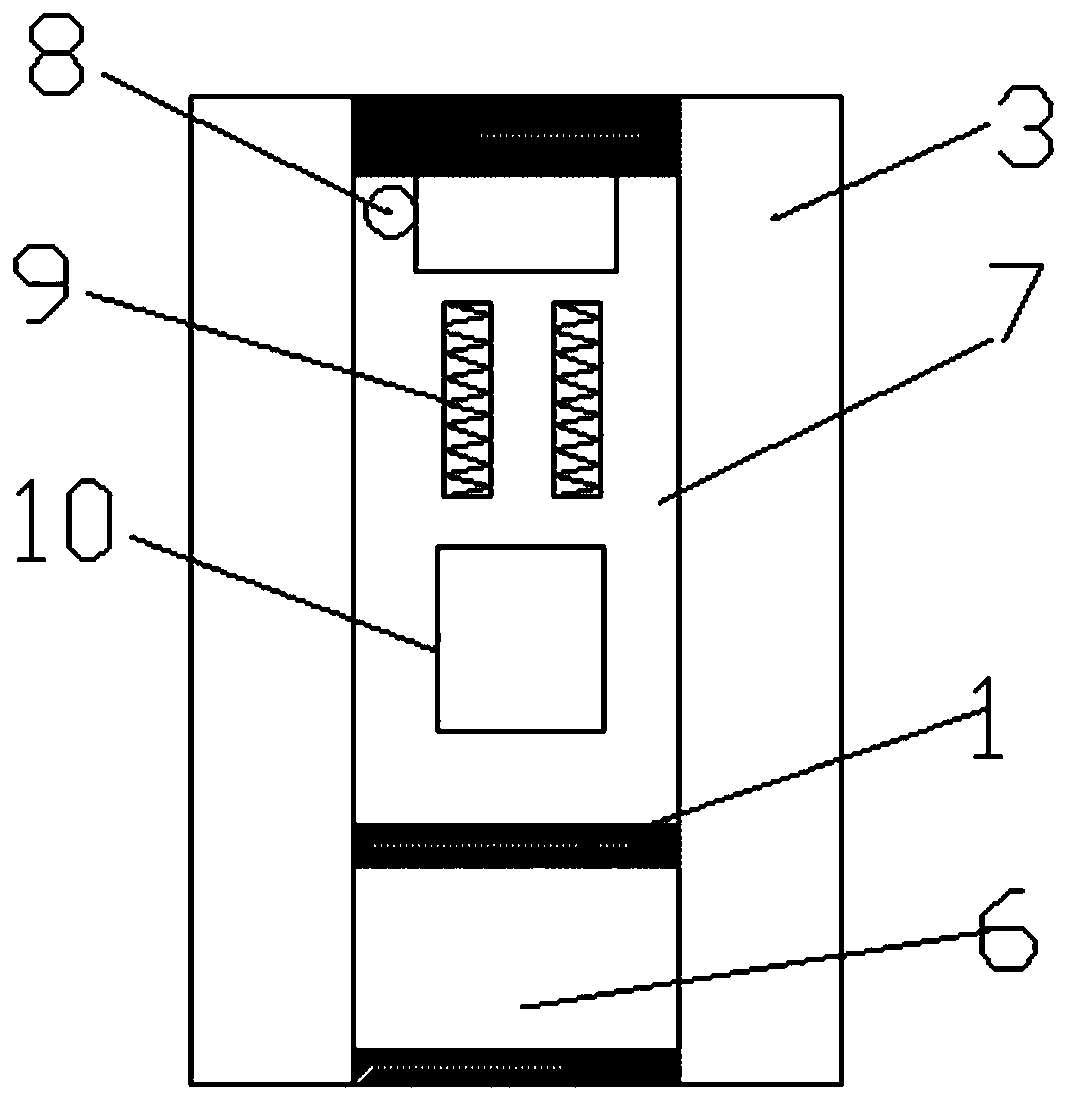

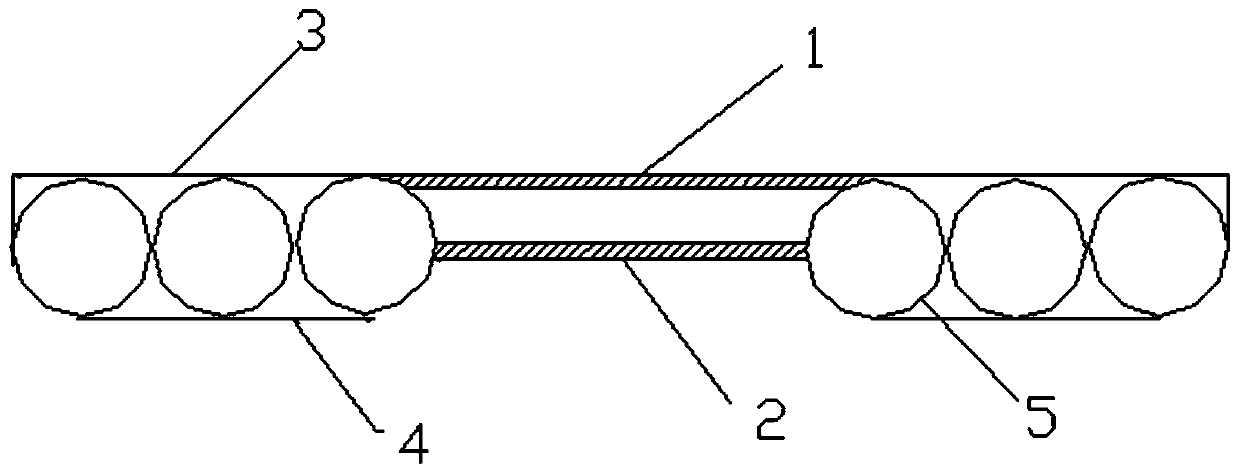

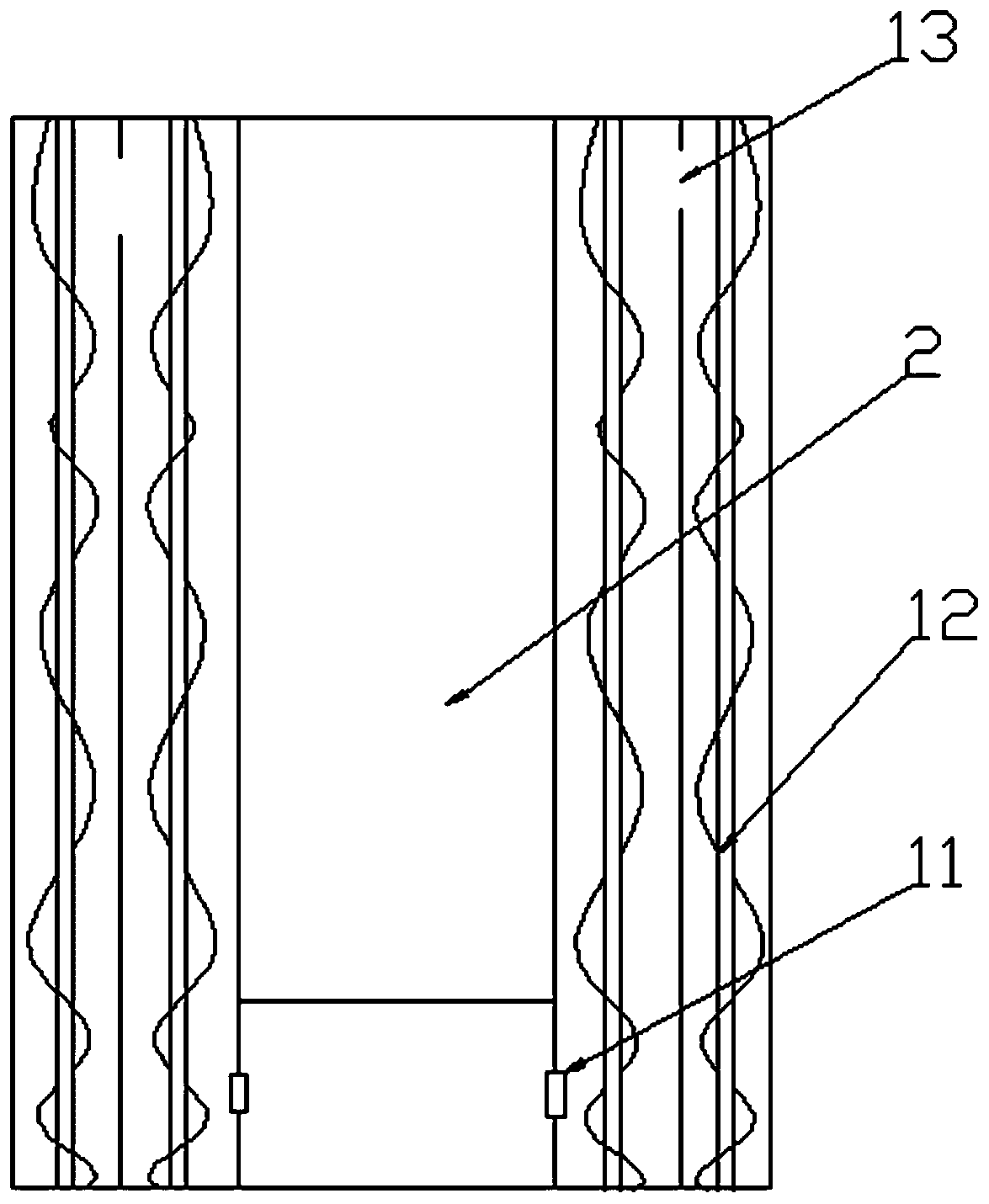

[0044] The floating body described in step S01 is as figure 1 and figure 2As shown, it includes the connecting plate 2 and the spiral ...

Embodiment 2

[0046] A method for mining and separating river dredged materials, using river dredged materials as raw materials, comprising the following steps:

[0047] S01 Use a sand pump to extract raw materials from the river and transport them to the floating body through pipelines;

[0048] S02 separates the natural sand from the gravel through the vibrating screen, and transports the natural sand to the sand tank;

[0049] After S03 stones are sieved, they are divided into large stones with a particle size greater than 4cm and small stones with a particle size less than or equal to 4cm;

[0050] S04 Crushing large stones and small stones respectively, transporting them to the sand making machine to prepare sand, and then transporting the sand to the sand tank;

[0051] S05 transports the sand in the sand pool to the sand field with a sand pump.

[0052] The floating body described in step S01 is as figure 1 and figure 2 As shown, it includes the connecting plate 2 and the spiral...

Embodiment 3

[0055] Embodiment 3 is basically the same as Embodiment 2, the difference is that step S01 transports the raw materials to the floating body and then stirs the raw materials (you can also add water appropriately according to the amount of water in the raw materials), discards the floating matter in the stirring process, and then puts The water is drained, and then magnetic separation is used to remove metal substances. The metals can be collected for reuse, and then continue to step S02; the stones obtained by sieving in S02 are stirred and soaked with an aqueous solution of bleaching powder for 0.5 to 1 hour. The mass concentration in the solution is 28-35%, the volume ratio of the aqueous solution of bleaching powder to the raw material is 1-2:1, then the solution is removed by filtration, and then sieved, that is, step S03; the rest of the steps are the same as in Example 2. Among them, the floating objects are mainly some plastics, wood chips and other substances. After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com