Lead screw drive based multistage synchronous telescopic boom

A screw-driven, telescopic arm technology, applied in transmissions, friction transmissions, belts/chains/gears, etc., can solve the problems of difficult processing and assembly, difficult to transform, and low telescopic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only for illustration and are not intended to limit the present invention.

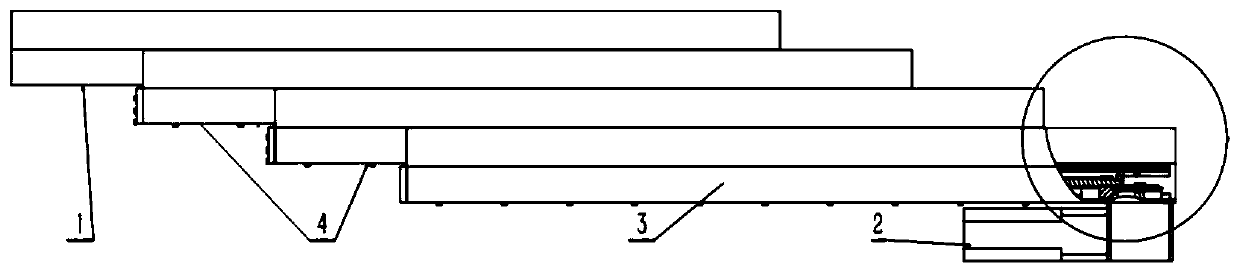

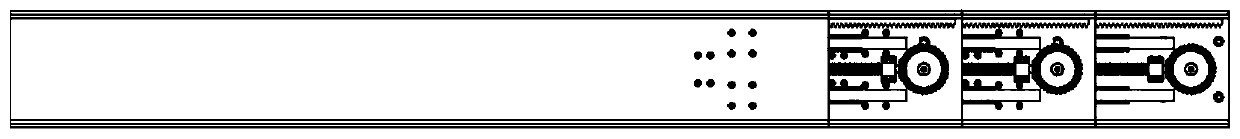

[0033] The invention provides a multi-stage synchronous telescopic arm driven by a lead screw, such as figure 1 As shown, it includes: a carrying section (1) and one or more telescopic arm units fixedly connected with the carrying section (1); wherein, each telescopic arm unit includes a servo drive motor (2), a primary telescopic drive section (3 ) and multi-stage telescopic middle section (4); figure 1 Take the middle section including two stages of expansion and contraction as an example, that is, figure 1 It is a four-stage synchronous telescopic boom, but the present invention is not limited to a four-stage synchronous telescopic boom. The number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com