Injection valve of multi-point injection engine added with mixer

A mixer and injection valve technology, which is applied in the direction of machine/engine, engine components, engine control, etc., can solve the problems of uneven mixing of mixed gas, large change of mixed gas concentration, and insufficient injection accuracy, so as to facilitate control and improve Effect of uniformity and accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

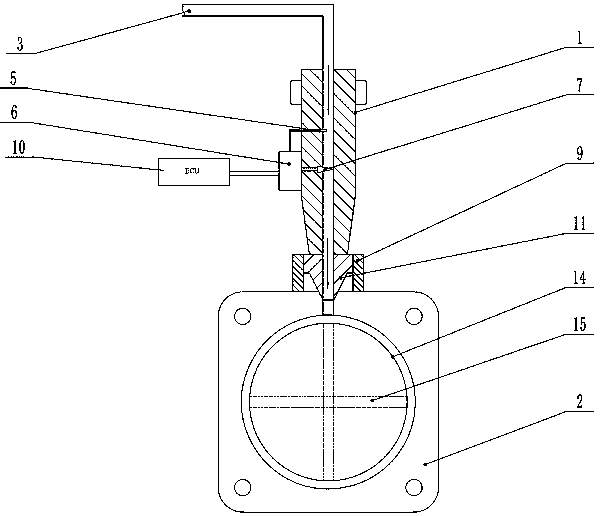

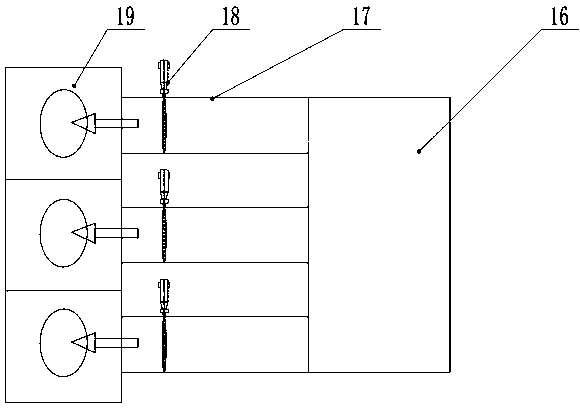

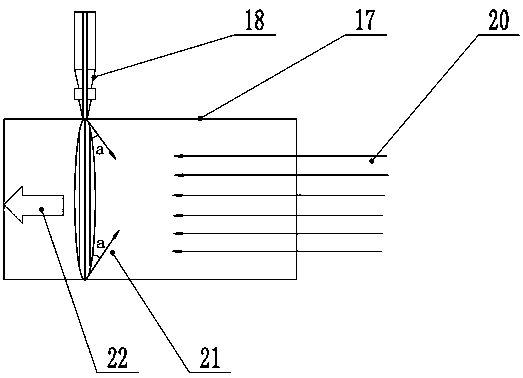

[0018] combine Figure 1~4 , an injection valve of a multi-point injection engine equipped with a mixer according to the present invention includes a multi-point injection valve body 1, a mixer 2, a gas pressure sensor 5, an injection valve controller 6, an injection valve needle 7, and a connecting valve seat 9. The mixer 2 is provided with a mixer conical sealing surface 11, the lower end of the multi-point injection valve body 1 is bonded and sealed with the mixer conical sealing surface 11, the mixer 2 is fixedly connected to the valve seat 9, and the valve seat 9 is connected to the valve The seat 9 fixes the lower end of the multi-point injection valve body 1, and the mixer 2 is provided with a mixer annular cavity 14 and a cross injection frame 15. The inner hole of the multi-point injection valve body 1 communicates with the mixer annular cavity 14 in the mixer 2, The inner side of the mixer annular chamber 14 is fixed with the cross end of the cross injection frame 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com