Wind deflection prevention jumper cross arm of 1000kV tension tower

A cross-arm and jumper technology, applied in the field of transmission line poles and towers, can solve the problems of angle steel bearing capacity damage or instability, safety production accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Best practice:

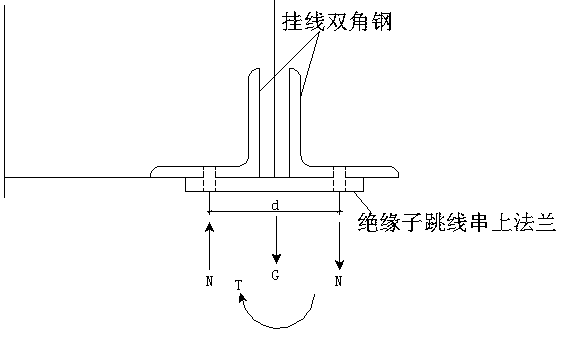

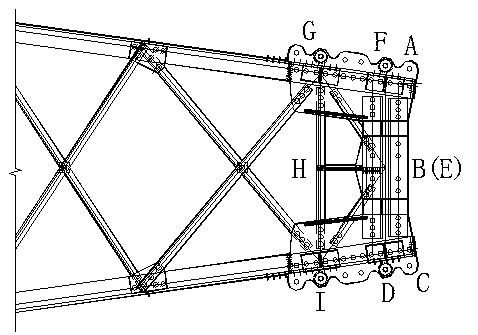

[0018] Refer to attached Figure 1-Figure 6 , 1000kV tension tower wind deflection jumper cross arm, including front upper horizontal angle steel JP, rear upper horizontal angle steel LR, front lower horizontal angle steel AG and rear lower horizontal angle steel CI, between front upper and lower horizontal angle steels and rear upper, There are several supporting slanting rods evenly distributed between the lower horizontal angle steels. The four horizontal angle steels have ACLJ as the outer end, and the direction in which the other end is connected to the tower body is the inner side. An outer truss ACLJ is installed at the outer ends of the four transverse angle steels, and an inner truss FDMO is also included, which is located on the side of the outer truss ACLJ close to the main pole and connected with the outer ends of the four transverse angle steels. The trusses are arranged side by side in parallel and are equipped with vertical V-shaped webs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com