External wall assembling structure of fabricated building and construction method of external wall assembling structure

An assembly structure and assembly technology, applied in the direction of building components, building structure, construction, etc., can solve the problems affecting the installation and abutment of wall panels, and achieve the effect that the seismic performance is not easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

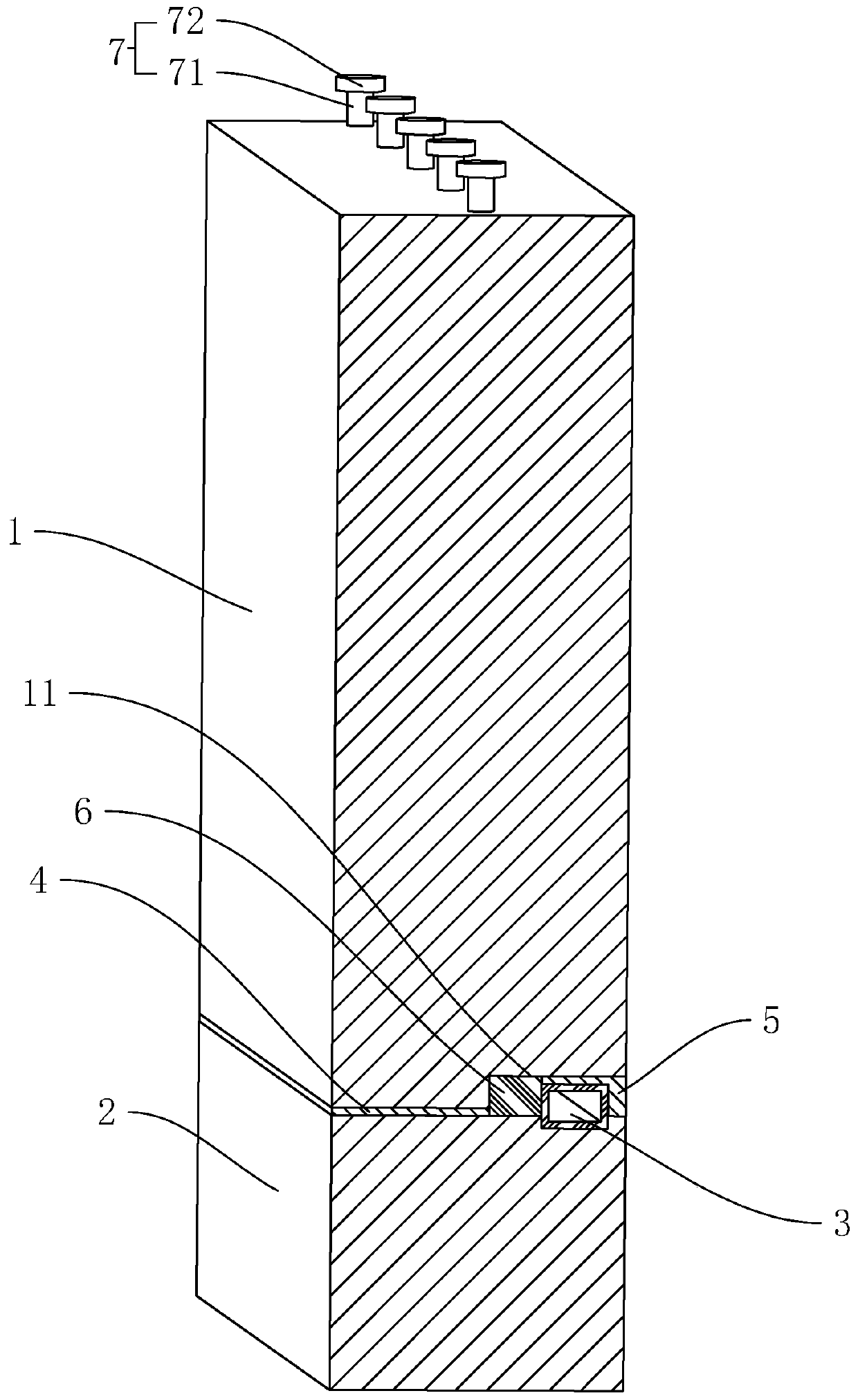

[0037] Embodiment 1: a kind of exterior wall assembly structure of prefabricated building, such as figure 1 As shown, it includes a number of vertically arranged wall panels 1, and beams 2 are arranged between the upper and lower adjacent wall panels 1. Plate 1 cast-in-place connection. The upper end of the beam 2 is provided with a square channel 3, which is a galvanized steel square tube, which abuts against the upper end of the unsolidified beam 2, and the two are fixed, and the square channel 3 is located at a position where the beam 2 is far away from the outer wall of the wallboard 1. The lower end of the wall panel 1 is provided with a waterproof groove 11, and the waterproof groove 11 penetrates the inner wall of the wall panel 1. When the lower end of the wall panel 1 above is in contact with the upper end of the beam 2, the top surface of the waterproof groove 11 is in contact with the upper surface of the square channel 3. . After the beam 2 is solidified, place t...

Embodiment 2

[0044] Embodiment 2: a kind of exterior wall construction method of prefabricated building, comprises the following steps:

[0045] S1, fixing a wall panel 1 to the foundation or the lower beam 2;

[0046] S2. Set up a formwork on the upper end of the installed wall panel 1, use concrete to pour the beam 2 in the plank, so that the beam 2 is connected with the load-bearing column;

[0047] S3. Place the square tube 3 on the upper end of the beam 2 that has not exceeded the initial setting time, insert the connecting column 31 of the square tube 3 into the beam 2, and make the lower end of the square tube 3 and the upper end of the beam 2 be on the same plane;

[0048] S4. Place the elastic member 6 on the upper end of the beam 2, make the elastic member 6 abut against the side wall of the square channel 3 facing the outer wall of the wall panel 1, place another wall panel 1 on the upper end of the completely solidified beam 2, and make the wall The lower end surface of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com