Gluing device used for plate edge sealing

A technology of gluing device and board, which is applied in the direction of adhesive application device, device for applying liquid to the surface, other plywood/plywood appliances, etc., can solve the problems of uneven gluing and complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

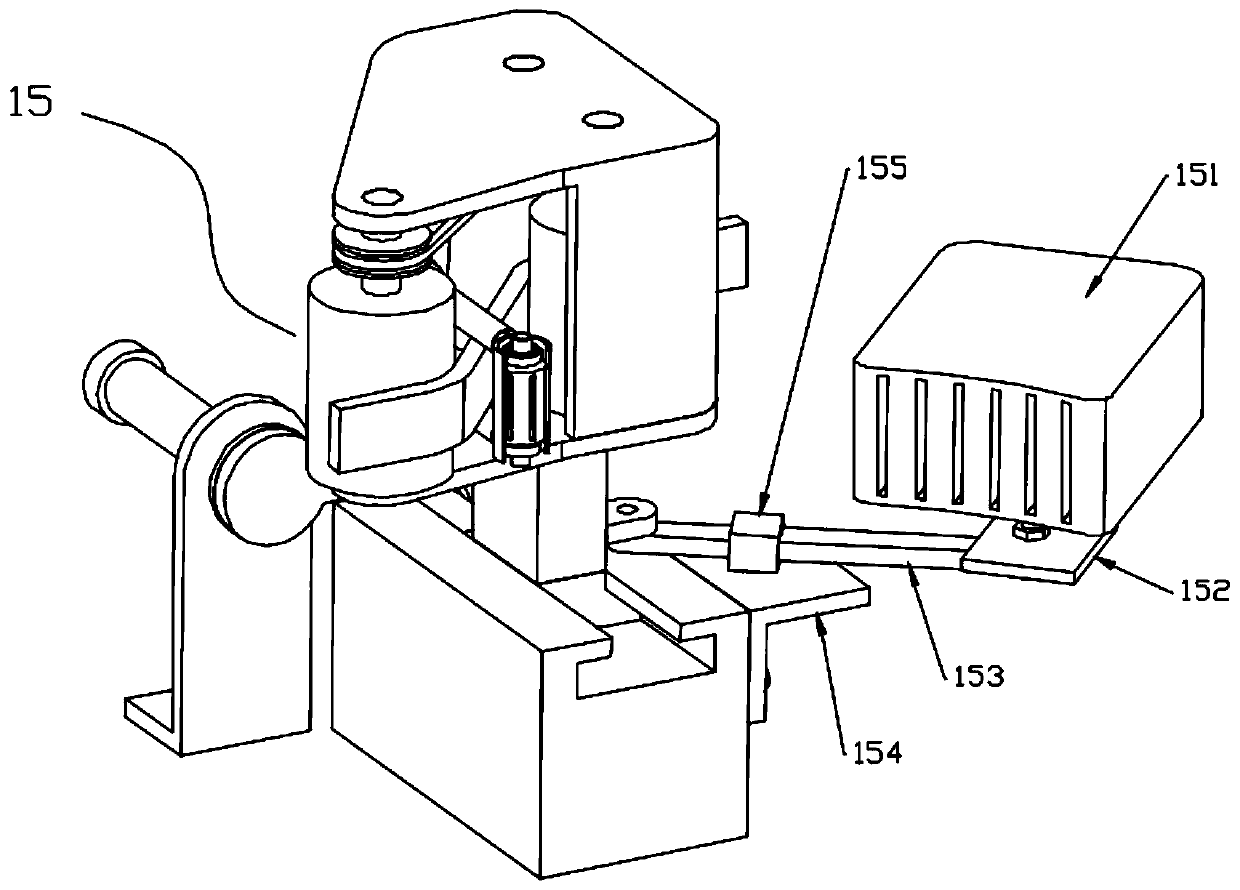

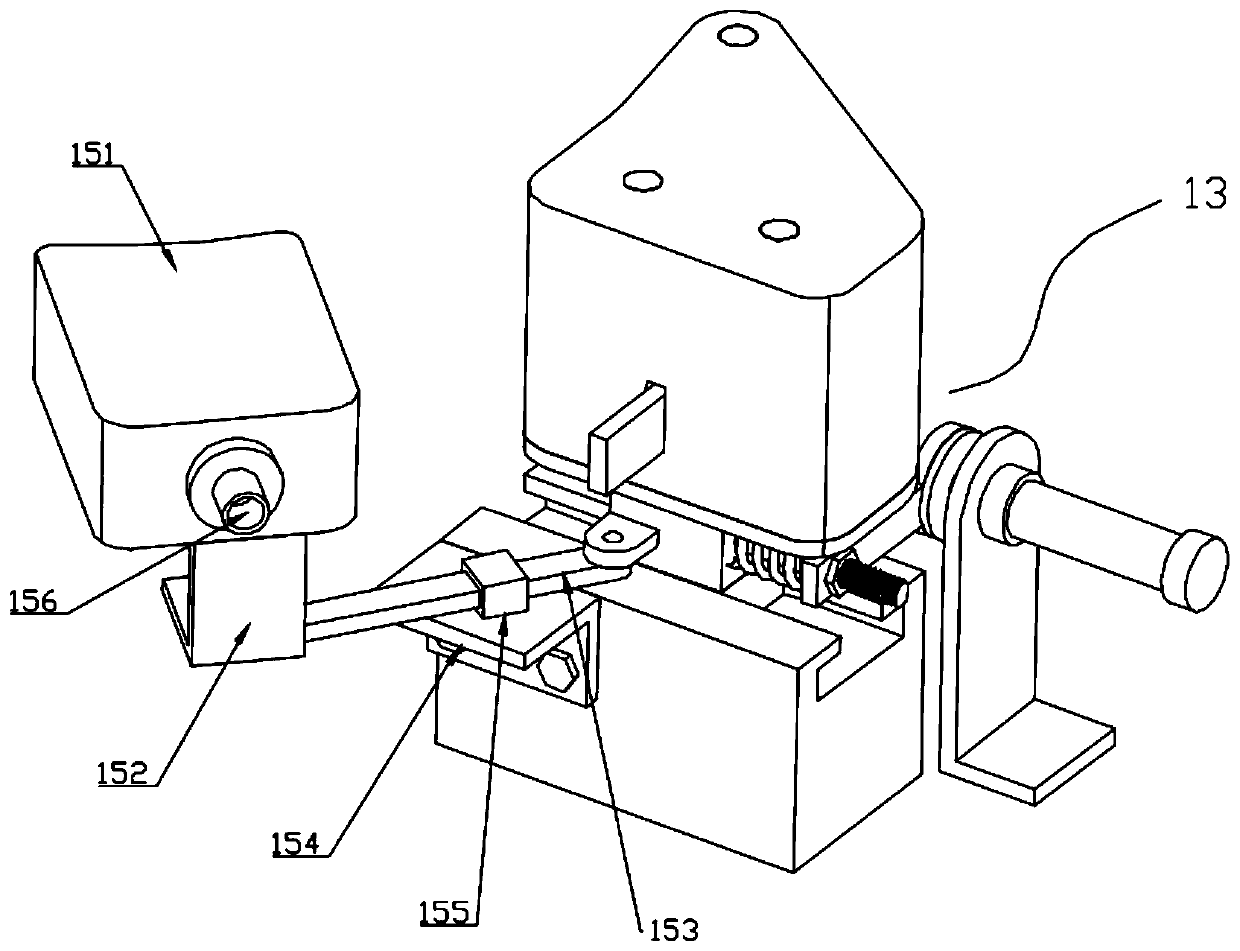

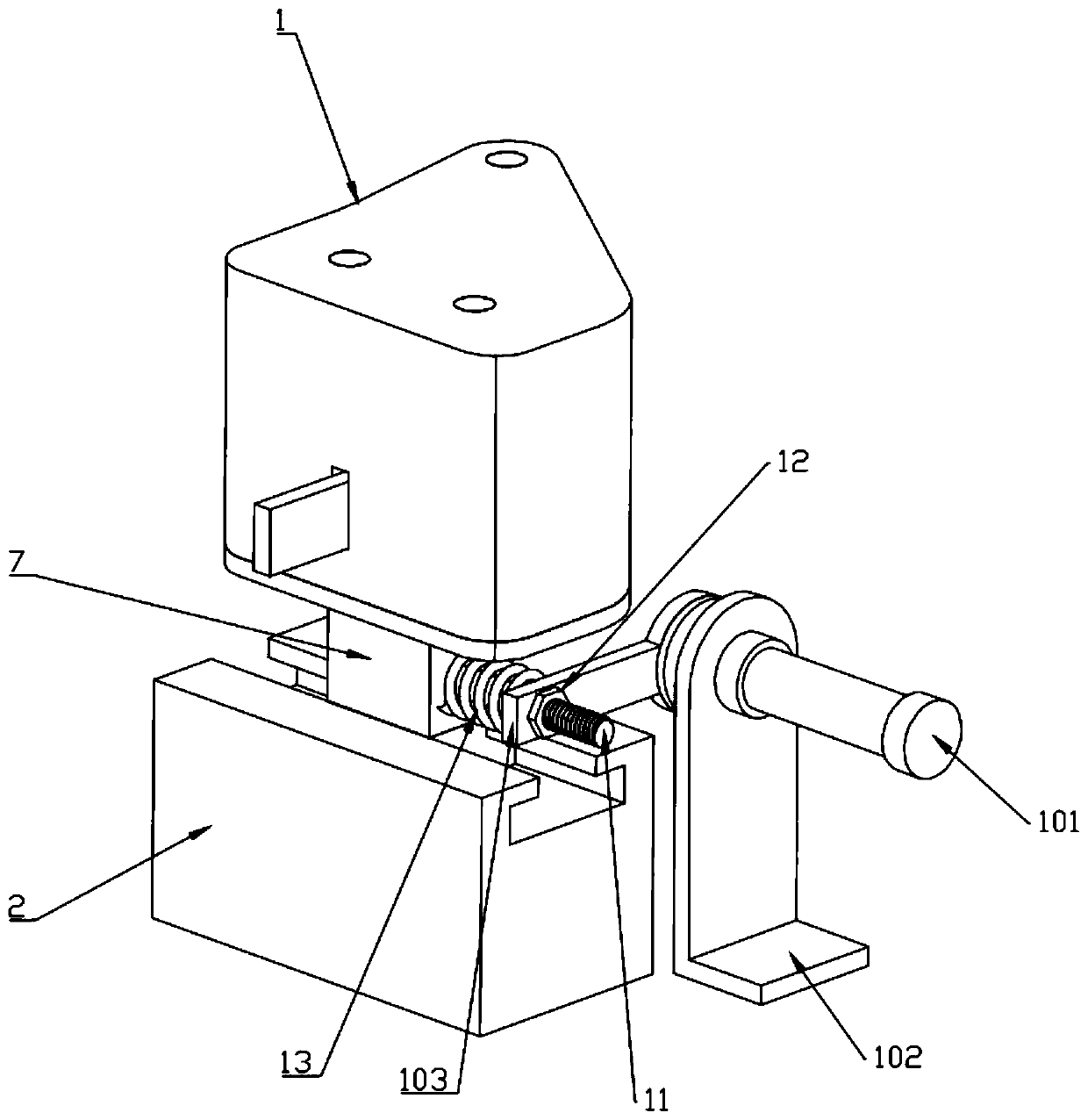

[0024] Such as Figure 1 to Figure 10 As shown, a gluing device for plate edge sealing includes a frame 1, a feed wheel 1, a feed wheel 2 3, a crimping wheel 4, a guide mechanism 5 and a gluing assembly 6, and the frame 1 The bottom is connected with a slide block 7, the slide block 7 is slidably connected on the slide rail 12, the slide block 7 is connected with a transverse drive mechanism 7 through a buffer assembly and realizes the horizontal movement of the slide block 7, the feed wheel one 2, the feed wheel two 3 The crimping wheels 4 are all rotatably connected in the frame 1, and there is a gap for the edge band to pass between the feeding wheel 1 2 and the feeding wheel 2 3, and the guide mechanism 5 is installed on the feeding wheel 2 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com