A method for solid-state fermenting tobacco stem cut stems with Rhododendron jelly

A technology of solid-state fermentation and Rhodotorula japonicus, which is applied in the fields of application, tobacco, and tobacco treatment, and can solve problems such as environmental pollution, high cost, and chemical reagent pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Slant culture: inoculate Rhodotorula gelatin strains on the slant medium (i.e. YEPD medium), and cultivate at 30°C for 2 days;

[0048] (2) Liquid seed culture: Inoculate the slant strain into a 250mL Erlenmeyer flask with 80mL seed medium, and cultivate it for 3 days at 30°C;

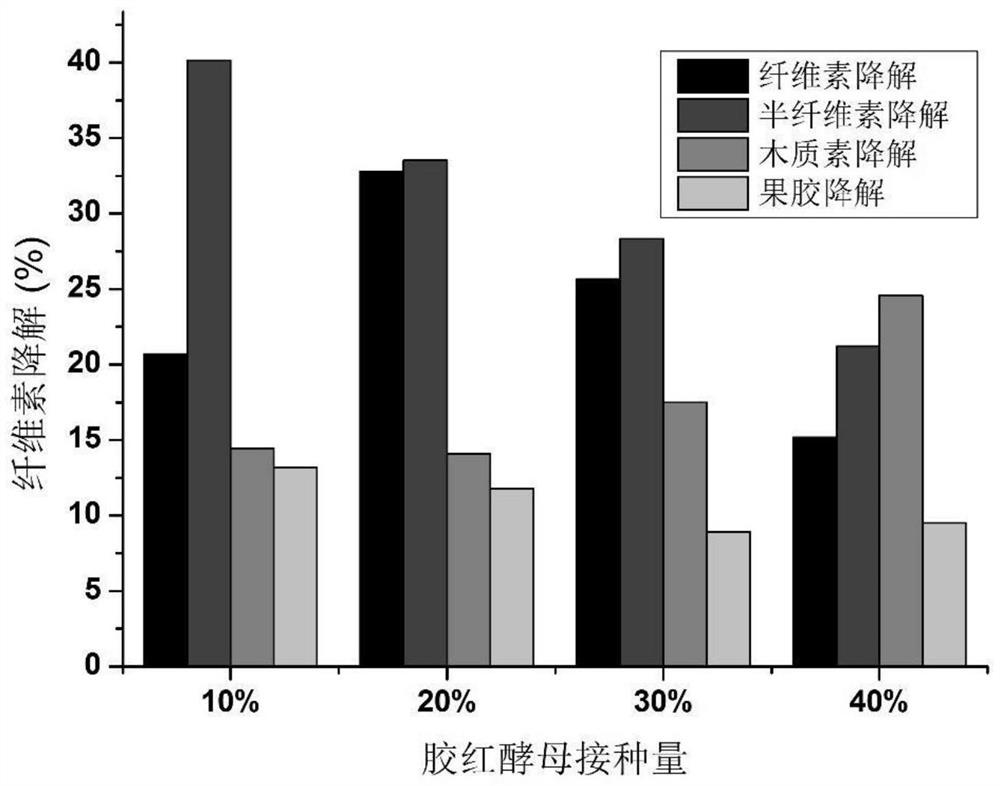

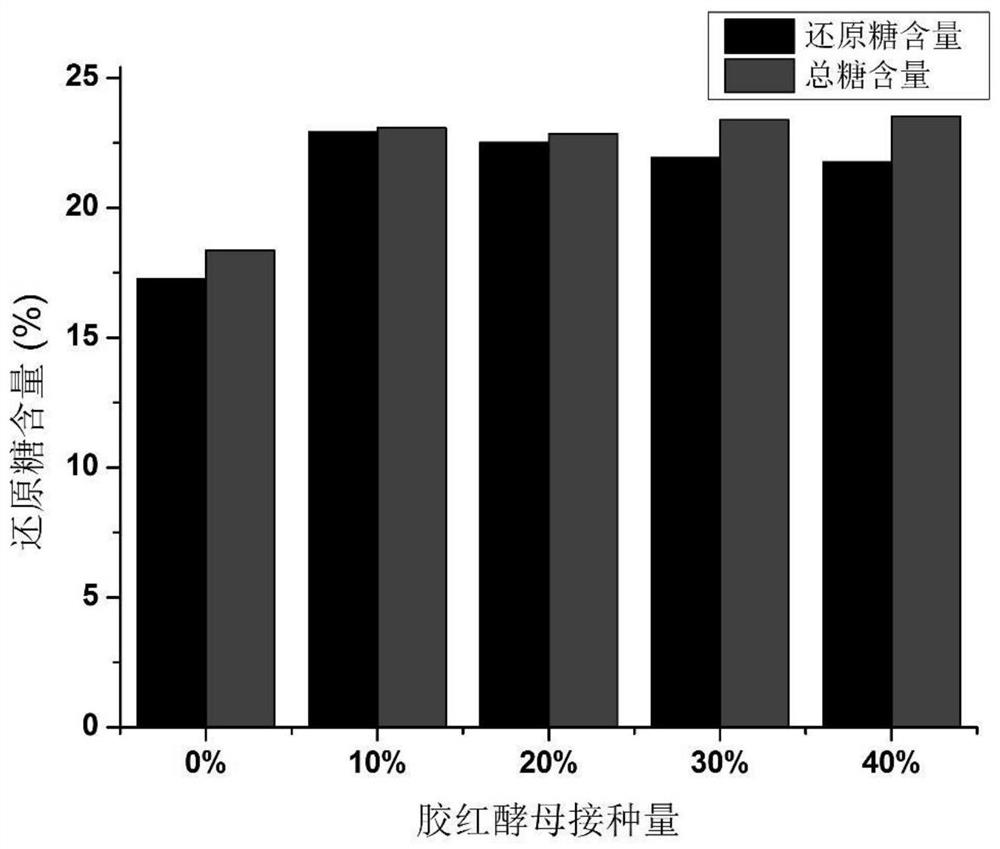

[0049] (3) solid-state fermentation culture: the cultured Rhodotorula gluei seed liquid is inoculated into the 500mL Erlenmeyer flask of the fermentation medium of tobacco stem shreds by 10% of the inoculum size, cultivated for 6 days at 30°C, Before fermentation, the contents of cellulose, hemicellulose, lignin and pectin were 585.4mg / g, 167.18mg / g, 96mg / g and 66.40mg / g respectively, and the contents of reducing sugar and total sugar were 17.25%, 18.36% %. After 6 days of fermentation, the measured cellulose degradation rate was 20.69%, the hemicellulose degradation rate was 40.15%, the lignin degradation rate was 14.46%, the pectin degradation rate was 13.20%, the reducing sugar increased...

Embodiment 2

[0053] The cultivated rhodotorula gum seed solution was inoculated into the 500mL Erlenmeyer flask of the fermentation medium of cut tobacco stems according to the inoculum size of 20%, and other conditions were the same as in Example 1, and the cellulose degradation was measured after the fermentation rate 32.81%, hemicellulose degradation rate 33.53%, lignin degradation rate 14.07%, pectin degradation rate 11.78%, reducing sugar content increased 30.55%, total sugar increased 24.51% (see table 2, figure 1 and figure 2 ).

[0054] When table 2 inoculum size is 20%, the substance content change that different culture time detects

[0055]

Embodiment 3

[0057] The cultivated Rhodotorula gluei seed solution was inoculated into the 500mL Erlenmeyer flask of the fermentation medium of cut tobacco stems by 30% of the inoculum size, and other conditions were the same as in Example 1, and the cellulose degradation was measured after the fermentation was finished. rate 25.68%, hemicellulose degradation rate 28.32%, lignin degradation rate 17.50%, pectin degradation rate 8.91%, reducing sugar content increased 27.13%, total sugar content increased 27.34% (seeing table 3, figure 1 and figure 2 ).

[0058] When the inoculum size of table 3 was 30%, the change of substance content detected in different culture time

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com