Movable transformer dustproof cover for hanging core

A dust cover, transformer technology, applied in the direction of transformer/inductor housing, transformer/inductor cooling, transformer/inductor components, etc., can solve the problem of PVC film and magnetic thin strips, strength and strength are not applicable, unable to carry out The lifting point and other problems are called to achieve the effect of simple production and connection, convenience and sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

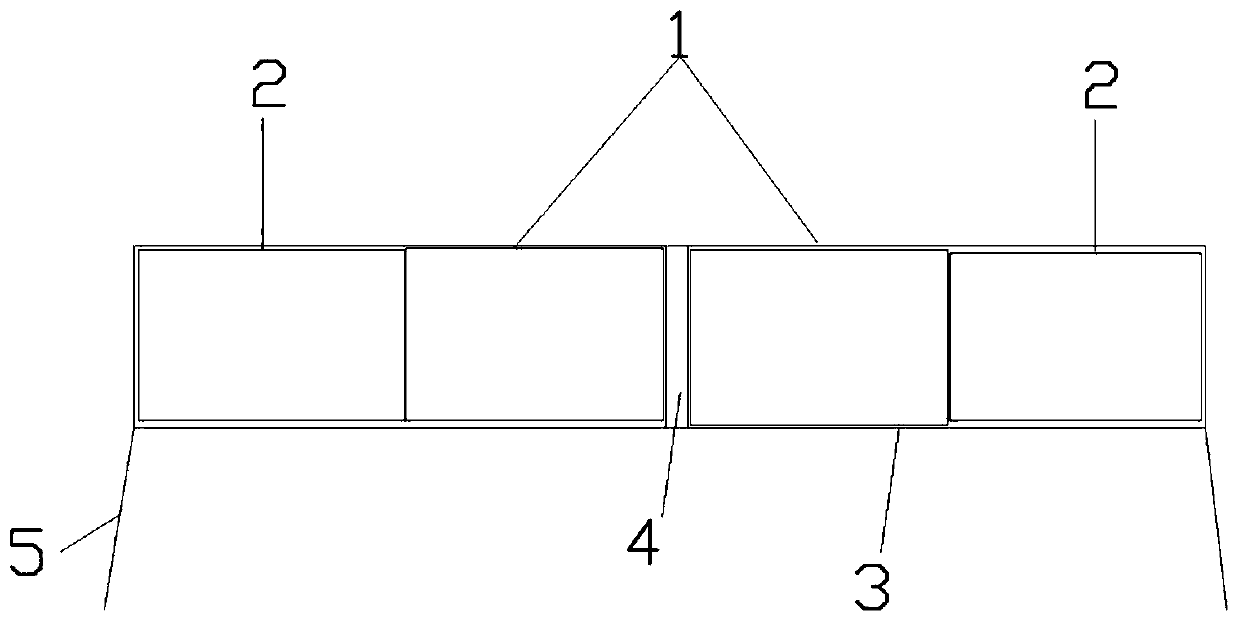

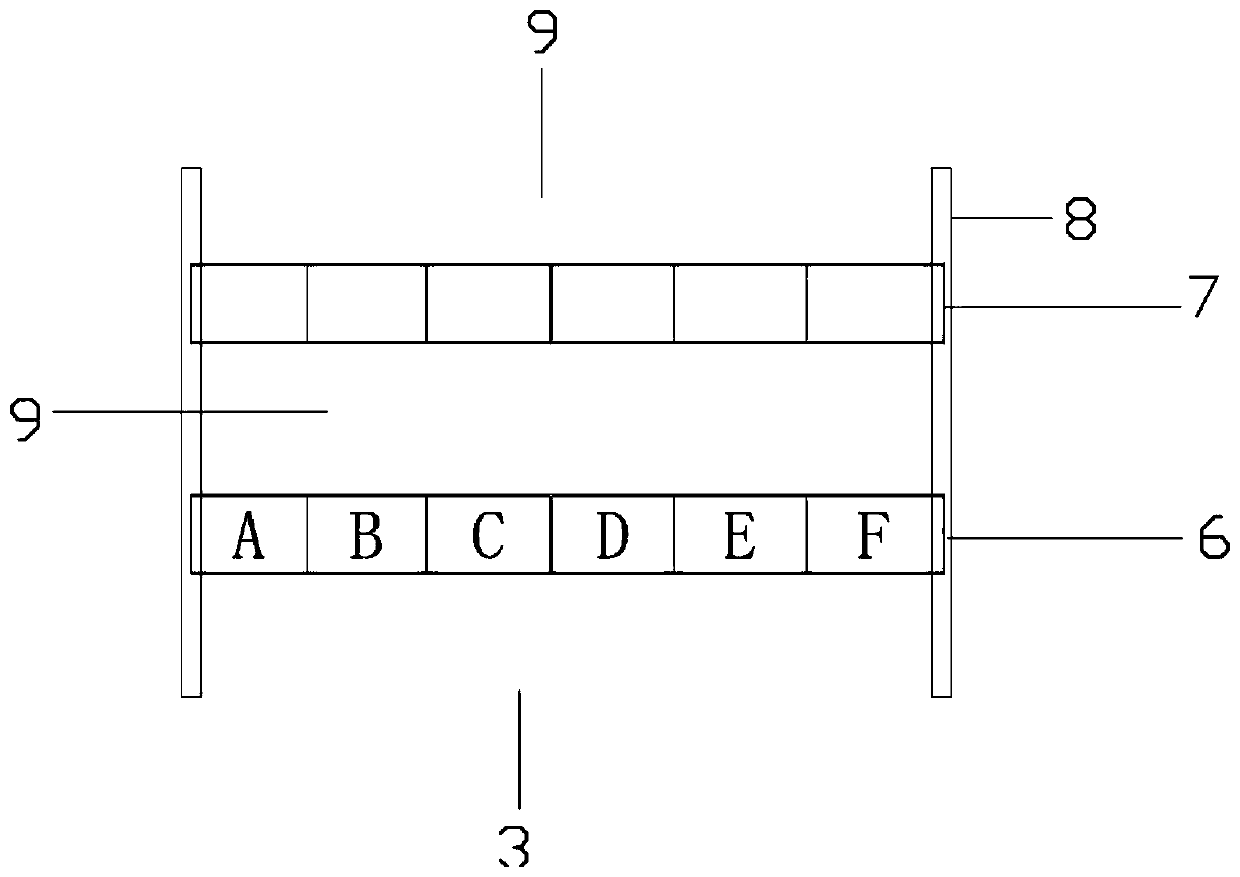

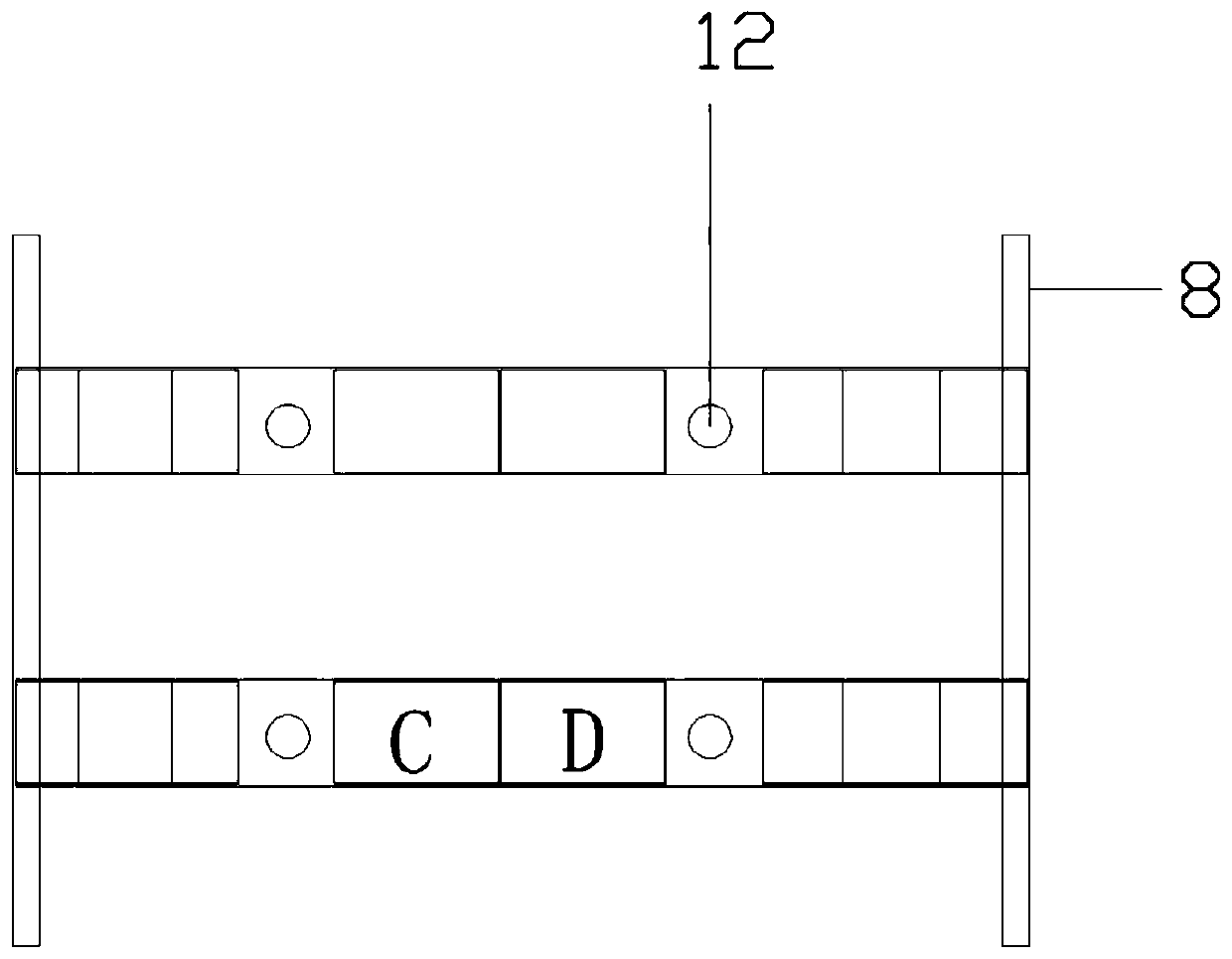

[0025] Such as figure 1 , a mobile dust cover for a transformer hanging core, including four angle steel frames 3, the frames 3 are connected and fixed by bolts to form a square frame, dust-proof windows 1 and glass windows 2 are arranged on each side of the frame, and can be used Movable clamping mode, so that the form can slide, the dustproof window 1 is located in the middle, the glass window 2 is located on both sides, the middle part of the angle steel frame 3 is provided with a cross column 4, which is used for supporting and limiting; the lower part of the angle steel frame 3 is The dustproof non-woven fabric 5 is set, thereby forming a cloth cover structure at the lower part of the dustproof cover. Preferably, two dust-proof windows and two glass windows are provided for dust-proof and observation of internal conditions. In order to adapt to different transformers, the size of the formed dust cover is preferably 6000mm in length, 3300 mm in width and 650 mm in height,...

Embodiment 2

[0029] This embodiment provides a structure of a dust-proof window on a dust-proof cover. The dust-proof part of the dust-proof window has three layers, including an activated carbon layer, a filter paper layer and a non-woven fabric layer. During production, the filter paper is used to wrap the activated carbon , the surroundings are glued to form a filter, and the outside of the filter is wrapped with non-woven fabric, and then fixed with the window frame. The size can be specifically set according to the size of the specific window opening. Preferably, activated carbon is particles that can adsorb PM3, so as to achieve the technical effects of dust prevention and ventilation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com