A kind of preparation method of nano conductive material/polymer composite gas sensor

A gas-sensing sensor and nano-conducting technology, which is applied in the direction of material analysis, material resistance, and material analysis by electromagnetic means, can solve the problems of long response time, small resistance change, and limit the application range of composite sensors, so as to improve the sensitivity, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

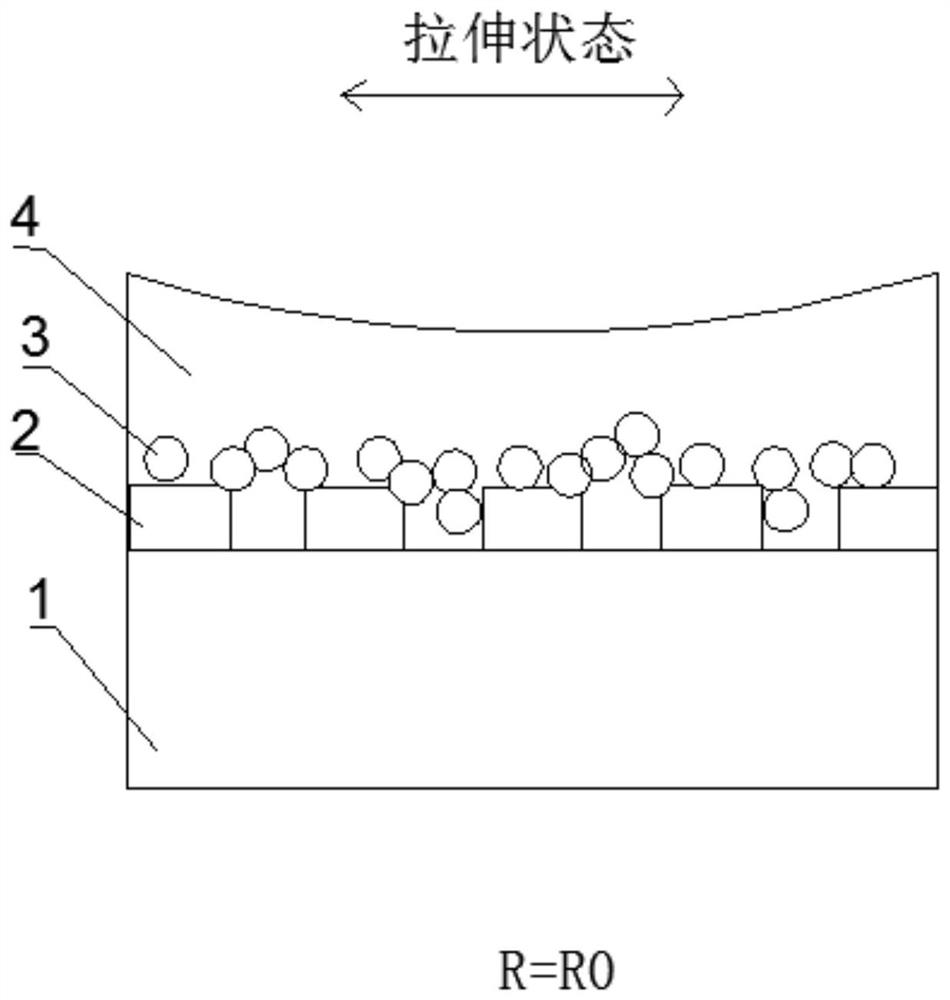

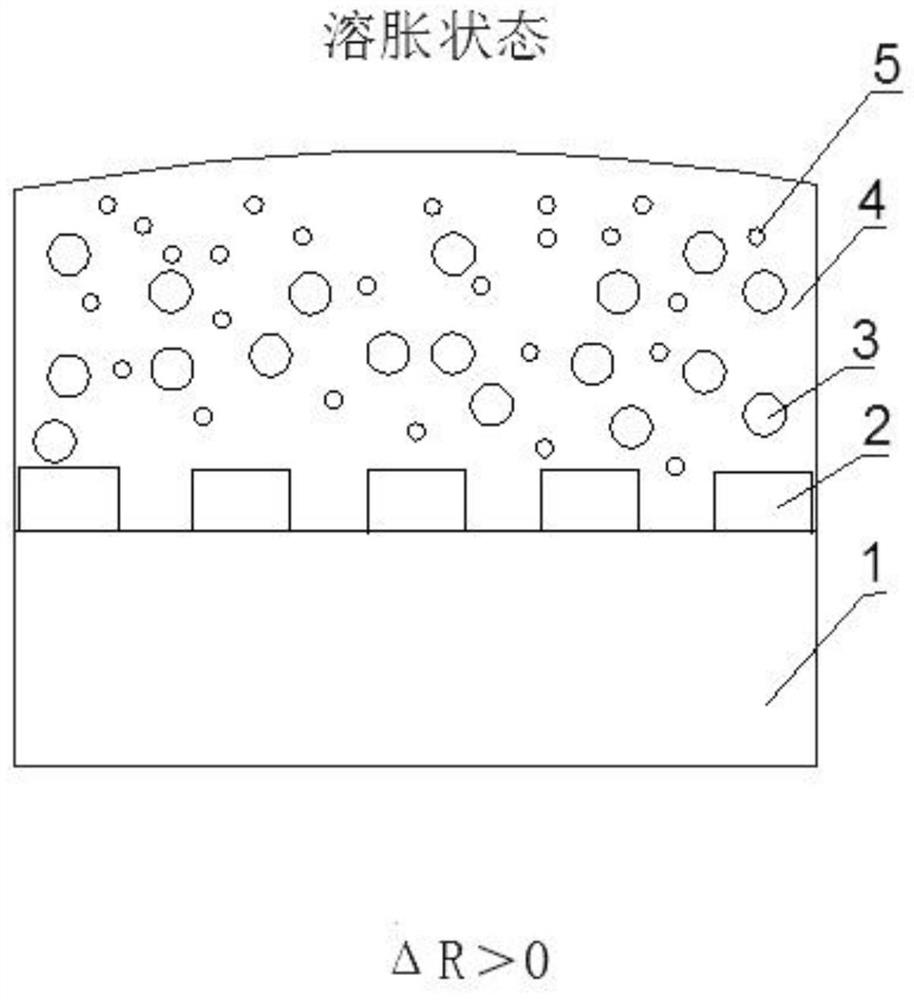

[0036] As shown in Figure 2, when the sensor is in a VOC vapor atmosphere, the VOC molecules 5 penetrate into the polymer 4 matrix,

Embodiment 2

[0047] (i) The prepared composite gas sensor is subjected to aging treatment.

[0060] In order to make the present invention more obvious and easy to understand, an implementation example based on the preparation method of the gas sensor of the present invention is provided,

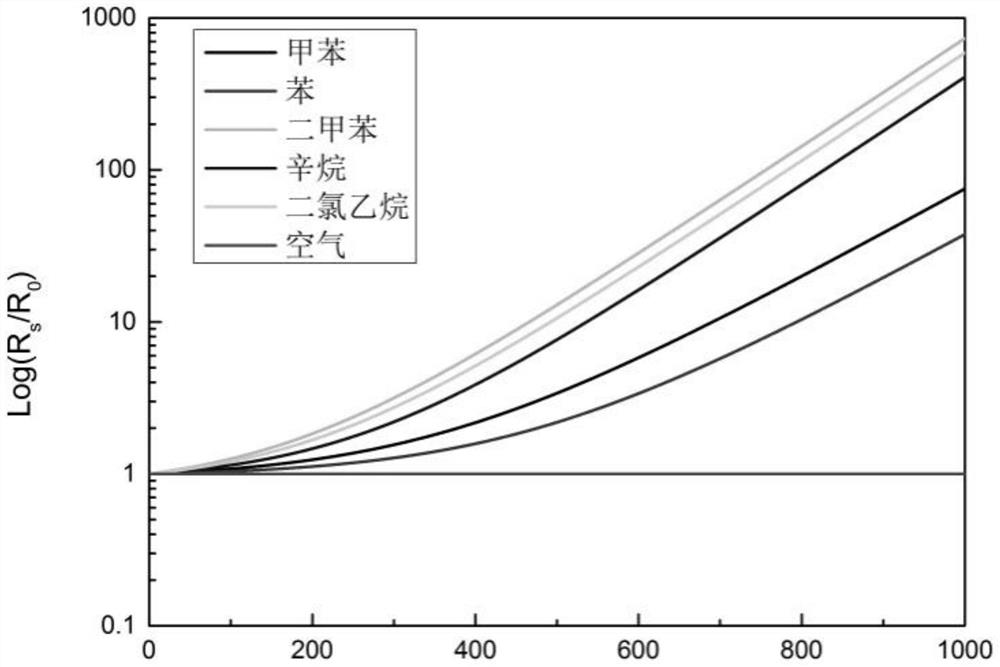

[0064] Under the standard test conditions, it is 29 ± 2 ° C, 65 ± 5% R.H, and the ordinate of Figure 3 represents the sensor resistance ratio Rs / R0, Rs

[0065] The ordinate of FIG. 4 represents the sensor resistance ratio Rs / R0, and the definitions of Rs and R0 are as follows: ΔR=sensor at various concentrations

[0066] The ordinate of FIG. 5 represents the sensor resistance ratio Rs / R0, and the definitions of Rs and R0 are as follows: Rs=sensor at various temperatures and humidity

[0067] The ordinate of FIG. 6 represents the sensor resistance ratio Rs / R0, and the definitions of Rs and R0 are as follows: Rs=sensor in different toluene

[0068] The real environment means that the concentration of no gas i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com