Rutting plate forming device with shear resistance testing function

A technology for testing function and molding device, which is applied in the direction of measuring device, preparation of test samples, and testing material strength by applying stable shear force, which can solve the problem of inconvenient demoulding, unrealistic temperature of rutted plate specimens, and complicated molding. and other problems, to achieve the effect of simple demoulding, avoiding damage, and reducing experimental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

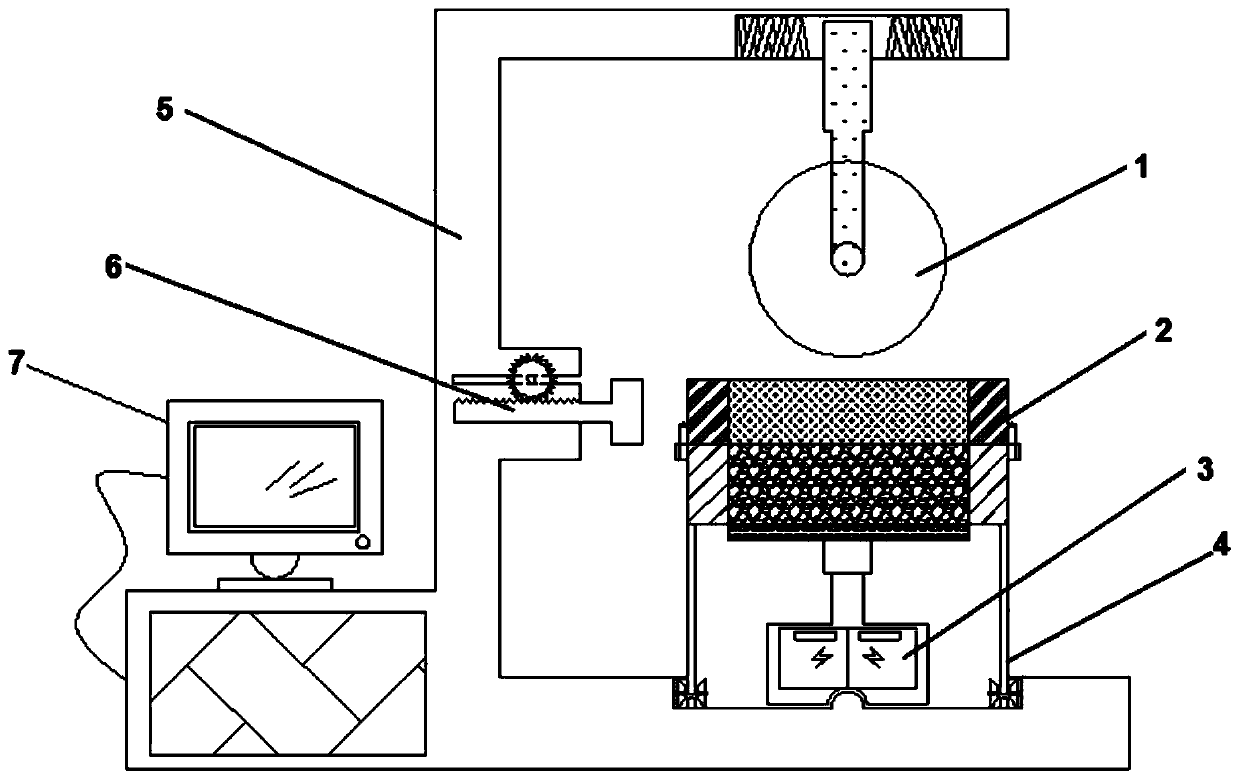

[0074] Example 1: Single-layer rut plate forming and non-destructive demoulding

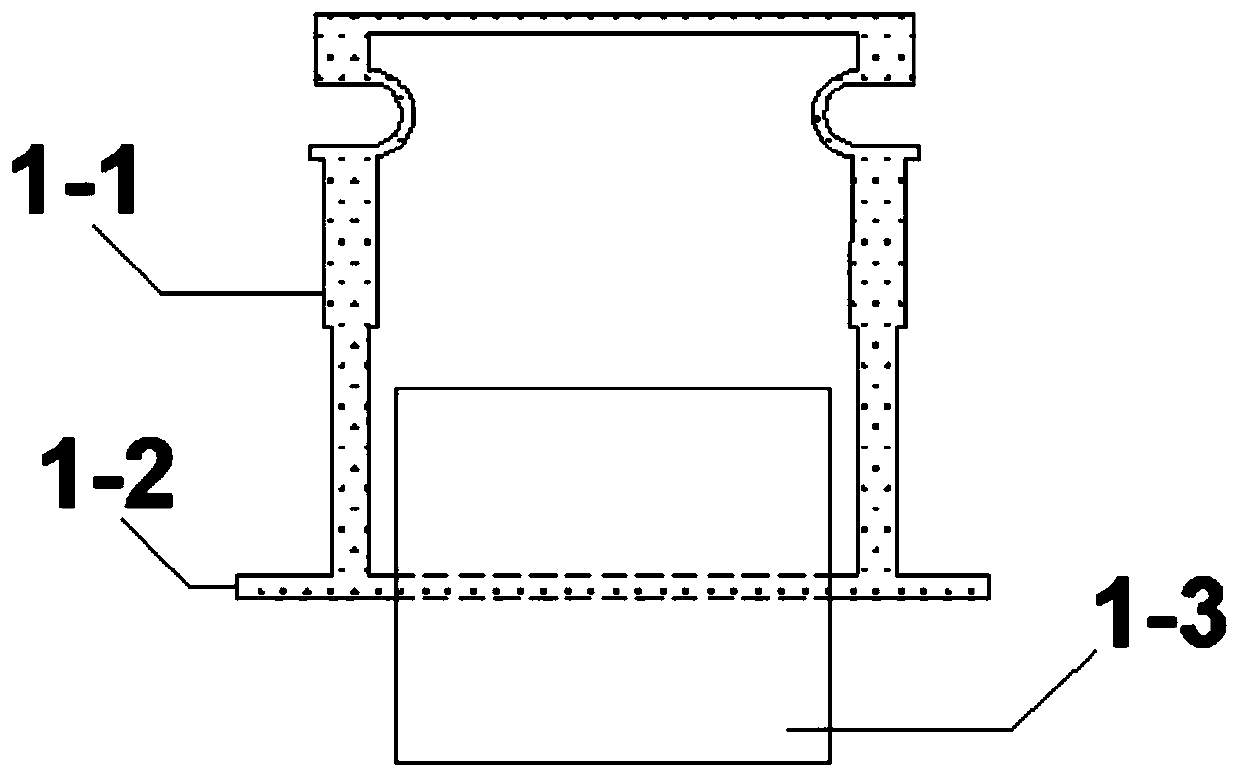

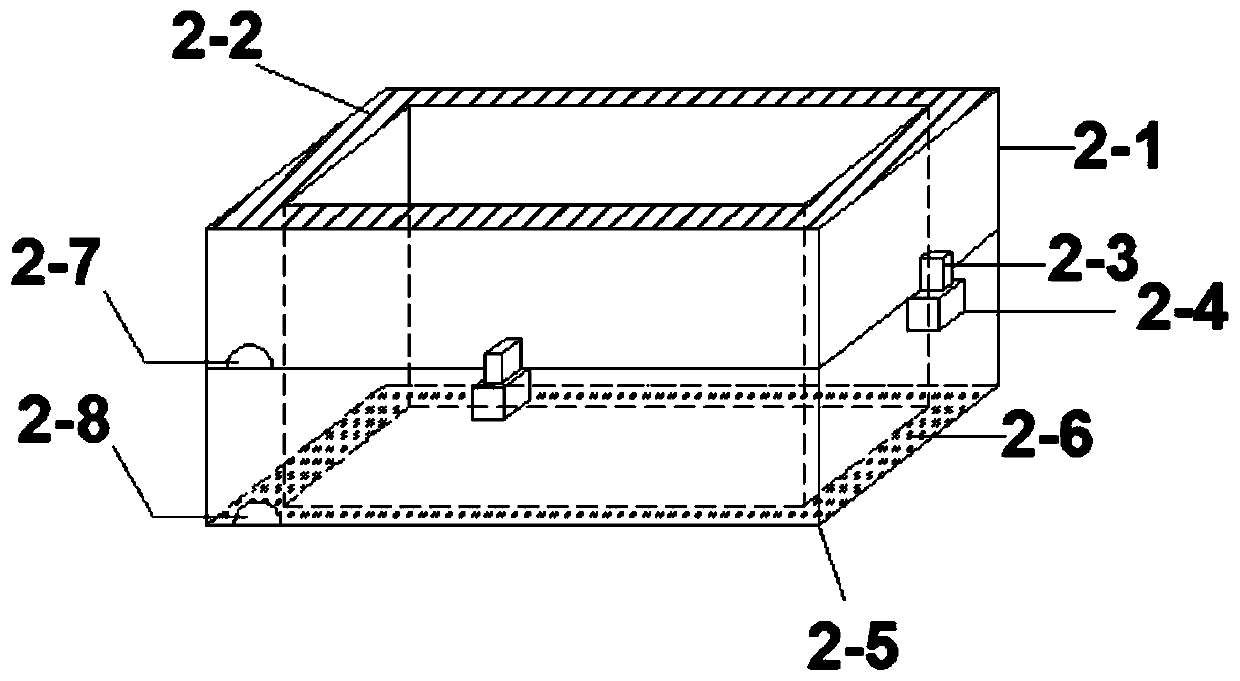

[0075] According to the test regulations of "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTGE20-2011), rut plates with different thicknesses were formed. Before use, preheat the rolling wheel 1-3 and the trial mold, and complete the steps 1 to 5 of the "forming and demoulding of single-layer rutting slabs" according to the above-mentioned "rutting slab forming" process, and in step 3 Set the rolling parameters as follows: total load 9kN, rolling twice in the same direction, so far the single-layer rutting slab is formed; after the specimen is cooled for 12 hours, complete step 6 of "single-layer rutting slab forming and demoulding" to the single-layer The demoulding of the rut plate is completed.

Embodiment 2

[0076] Example 2: Double-layer rutting plate forming and non-destructive demoulding

[0077] According to the test regulations of "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTGE20-2011), rut plates with different thicknesses were formed. Before use, preheat the rolling wheel 1-3 and the test mold, and complete the steps 1 to 7 of the "double-layer rutting plate forming and demoulding" according to the above-mentioned "rutting plate forming" process, and set in step 3 Rolling parameters are: total load 9kN, rolling twice in the same direction, so far the double-layer rutting slab is formed; after the specimen is cooled for 12 hours, complete step 8 of "forming and demoulding of the double-layer rutting slab", and the double-layer rutting slab is now formed. The demoulding of the rut plate is completed.

Embodiment 3

[0078] Embodiment 3: Asphalt mixture shear performance test

[0079] According to the test procedure of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTGF40-2004), according to the above-mentioned "asphalt mixture shear performance test" process, the shear performance of asphalt mixture is tested, and the maximum shear when the specimen is damaged is recorded. stress.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com