Novel oven

An oven, a new type of technology, applied in drying, dryer, lighting and heating equipment and other directions, can solve the problems of inconvenient handling of the oven, low drying efficiency, uncontrollable temperature of the drying oven, etc., and achieve the effect of heating and drying Good, improve drying efficiency, speed up drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

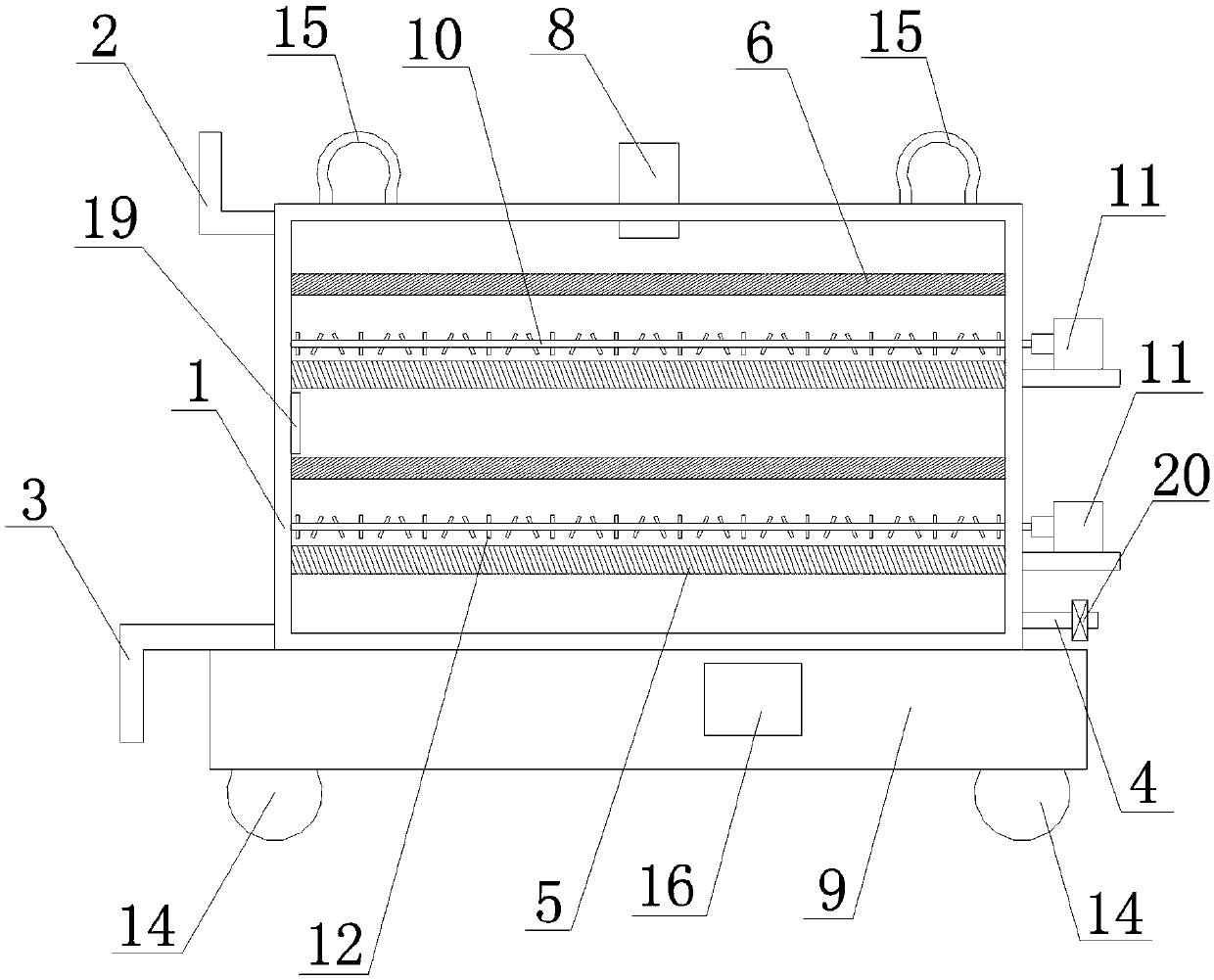

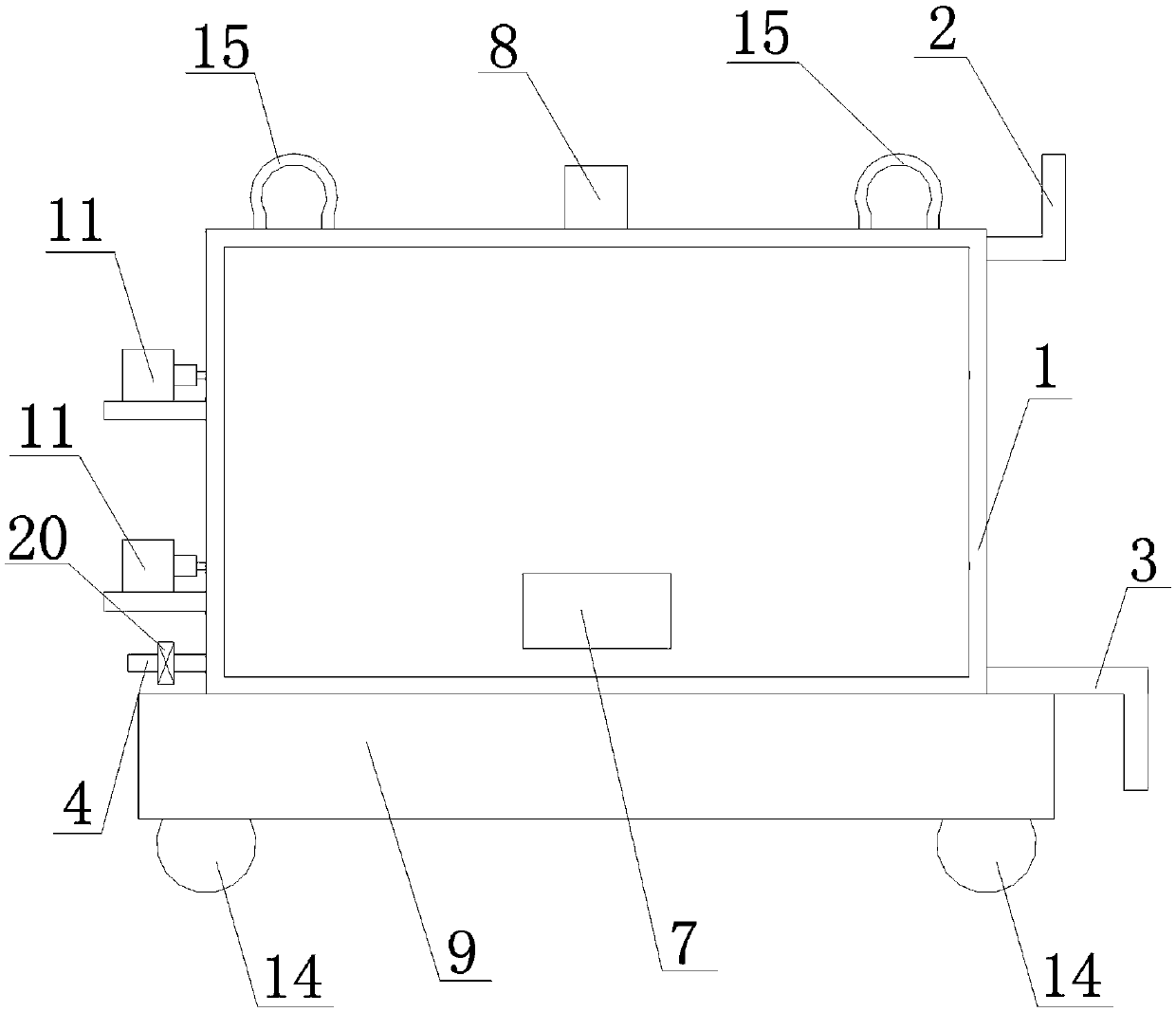

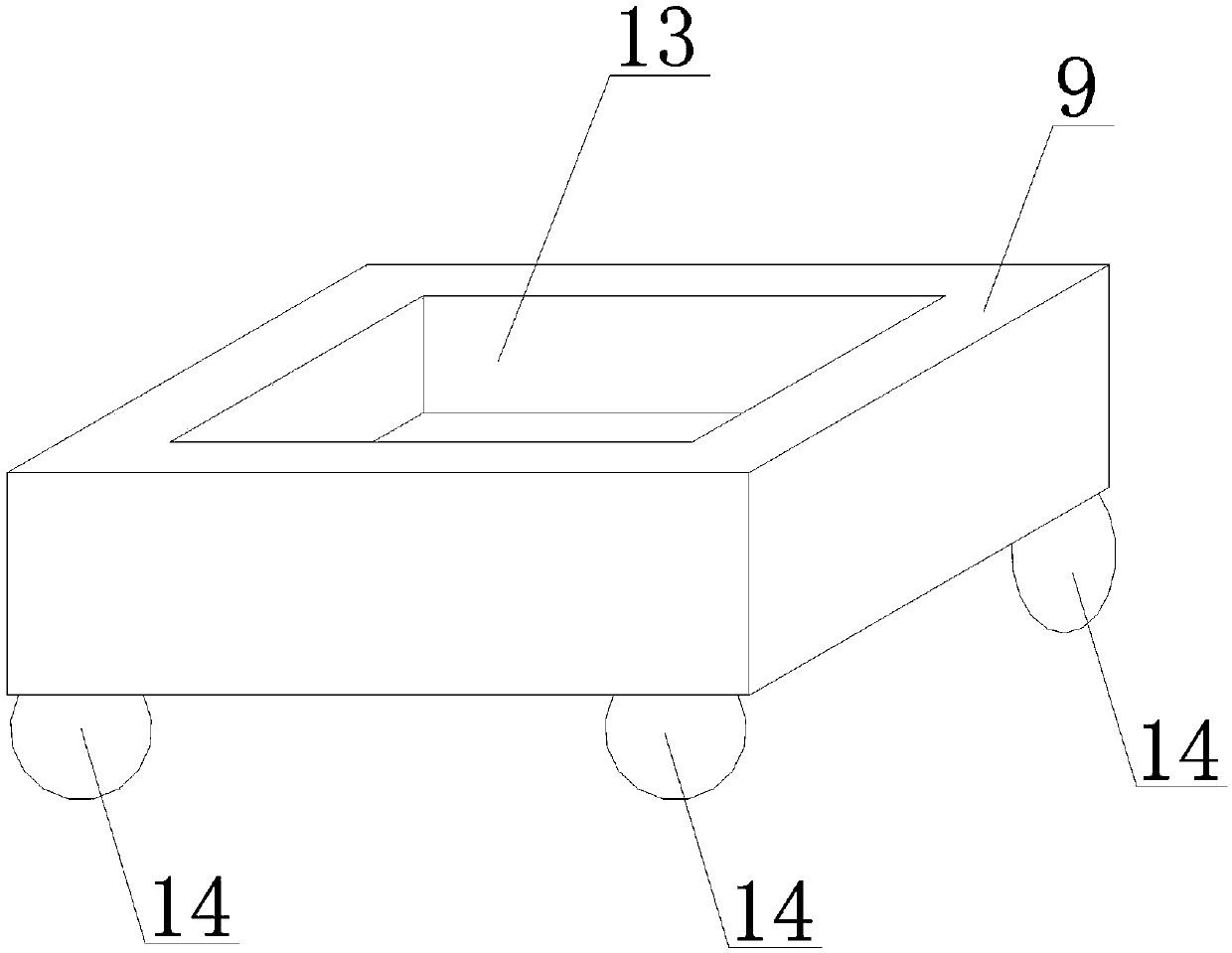

[0017] Such as Figure 1-3 As shown, the novel oven of the present invention comprises a square oven shell 1 with a double-layer structure, and the top and bottom of one side of the oven shell 1 are respectively provided with a steam outlet pipe 2 and an outlet pipe 2 communicated with the inner cavity of the double-layer structure of the oven shell 1. Water pipe 3, the lower part of the other side of the oven shell 1 is provided with a steam inlet pipe 4 communicating with the inner cavity of the double-layer structure of the oven shell 1, and the lower part of the back of the oven shell 1 is provided with the oven shell 1. The drying chamber communicates with the hot air blower 7 used to deliver dry hot air to the drying chamber through pipelines, and the top surface of the oven shell 1 is provided with an air outlet pipe 8 communicating with the drying chamber in the oven shell 1 .

[0018] In the present invention, the outer casing of the oven is double-layered, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com