Protective film for liquid crystal display and preparation process of protective film

A liquid crystal display and preparation process technology, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve problems such as the inability of the protective film to meet special occasions, the complex attaching process of the protective film, and the peeling of the protective film. , to achieve the effect of saving the sticking process, reasonable preparation process design and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

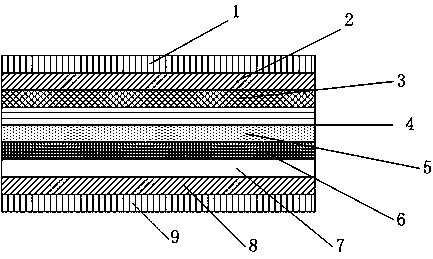

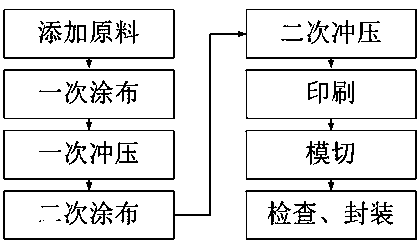

[0014] like Figure 1 to Figure 2 As shown, the liquid crystal display protective film of the present invention includes a first ink layer 1, a first PET (polyethylene terephthalate) release film 2, a silica gel layer 3, and a PU (polyurethane) adhesive layer 4 , PET substrate 5, acrylic adhesive layer 6, anti-scratch adhesive layer 7, second PET release film 8, second ink layer 9, the bottom surface of the first ink layer 1 and the top surface of the first PET release film 2 connected, the bottom surface of the first PET release film 2 is connected to the top surface of the silica gel layer 3, the bottom surface of the silica gel layer 3 is connected to the top surface of the PU adhesive layer 4, and the bottom surface of the PU adhesive layer 4 is connected to the top surface of the PE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com