Clamping jaw mechanism for round tube loading and unloading

A round tube and material clip technology, which is applied in the field of round tube loading and unloading jaw mechanisms, can solve the problems of easily damaged round tube detail structure, defective products, labor-intensive and other problems, so as to ensure accurate clamping, time saving, and feeding position. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

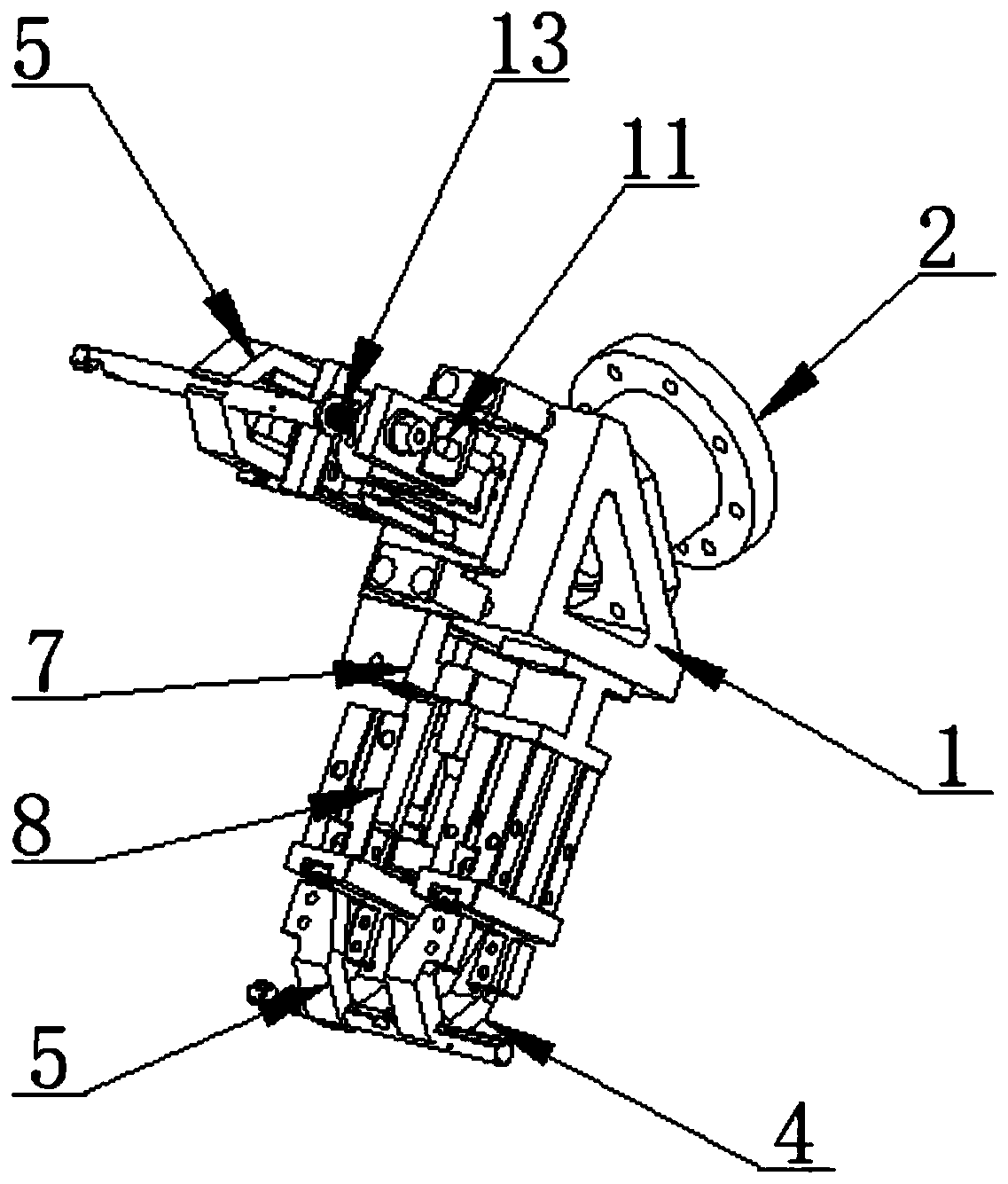

[0017] Embodiment: A gripper mechanism for loading and unloading round pipes, including a gripper mounting seat 1, a connecting seat 2, a gripper 3 for discharging finished round pipes, a gripper 4 for discharging waste materials in round pipes, and a gripper 5 for loading round pipes. Gripper conversion driving device and control system, the jaw mounting base 1 is rotatably installed on the connection base 2, the jaw conversion driving device drives the jaw mounting base 1 to rotate, and the clamping jaw mounting base 1 is spaced along its rotation direction There are a first installation surface and a second installation surface, the round tube finished product blanking jaw 3 and the round tube waste material blanking jaw 4 are coaxially installed on the first installation surface, and the round tube feeding jaw 5 is installed on the second On the second installation surface, the circular tube finished product blanking jaw 3 and the circular tube waste material blanking jaw 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com