PCB detection and wiping integrated machine

A technology of PCB board and all-in-one machine, applied in the field of PCB board detection and wiping all-in-one machine, can solve the problems of PCB board gold finger damage, increase production cost, insecurity, etc., to speed up production efficiency, improve effect, and save production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

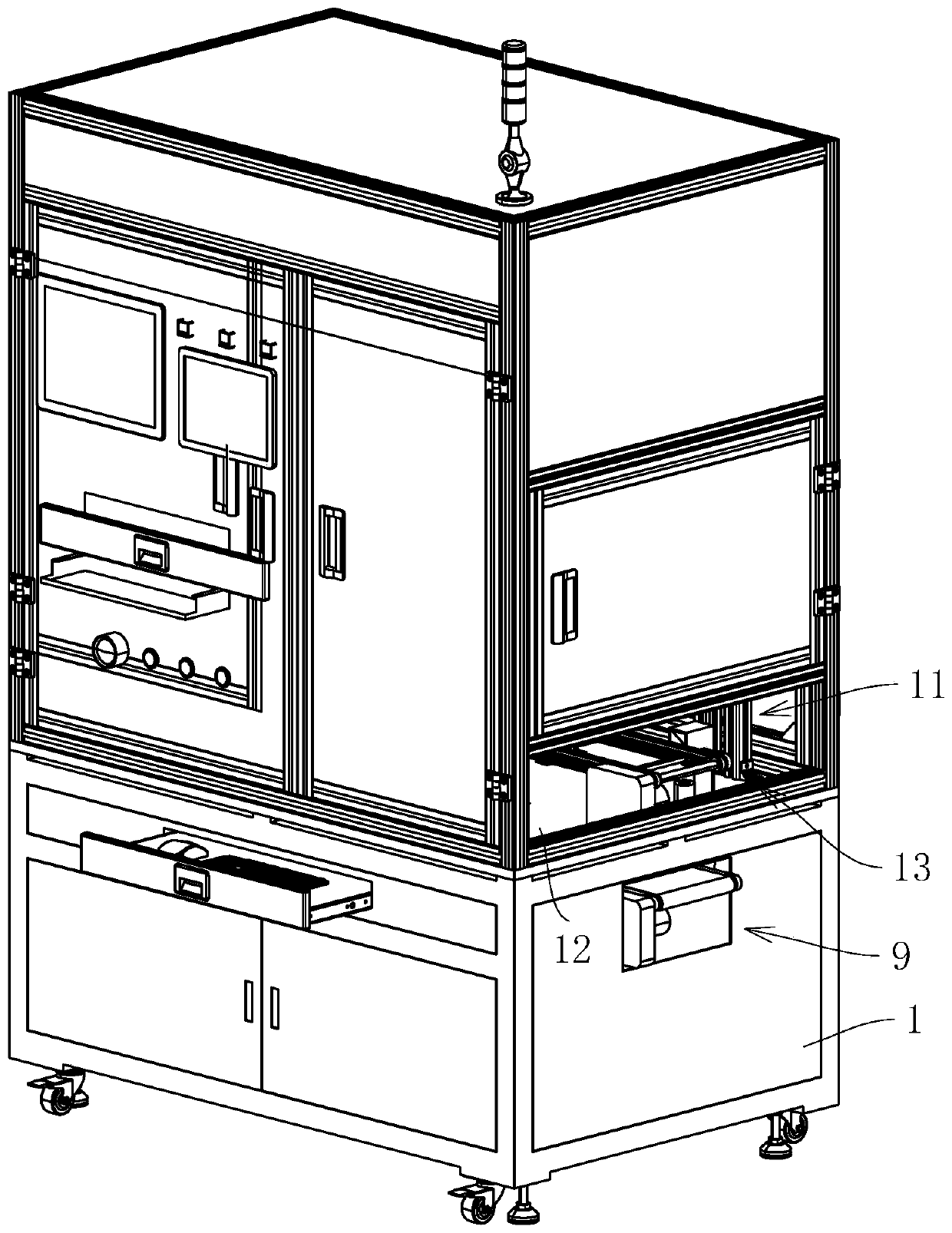

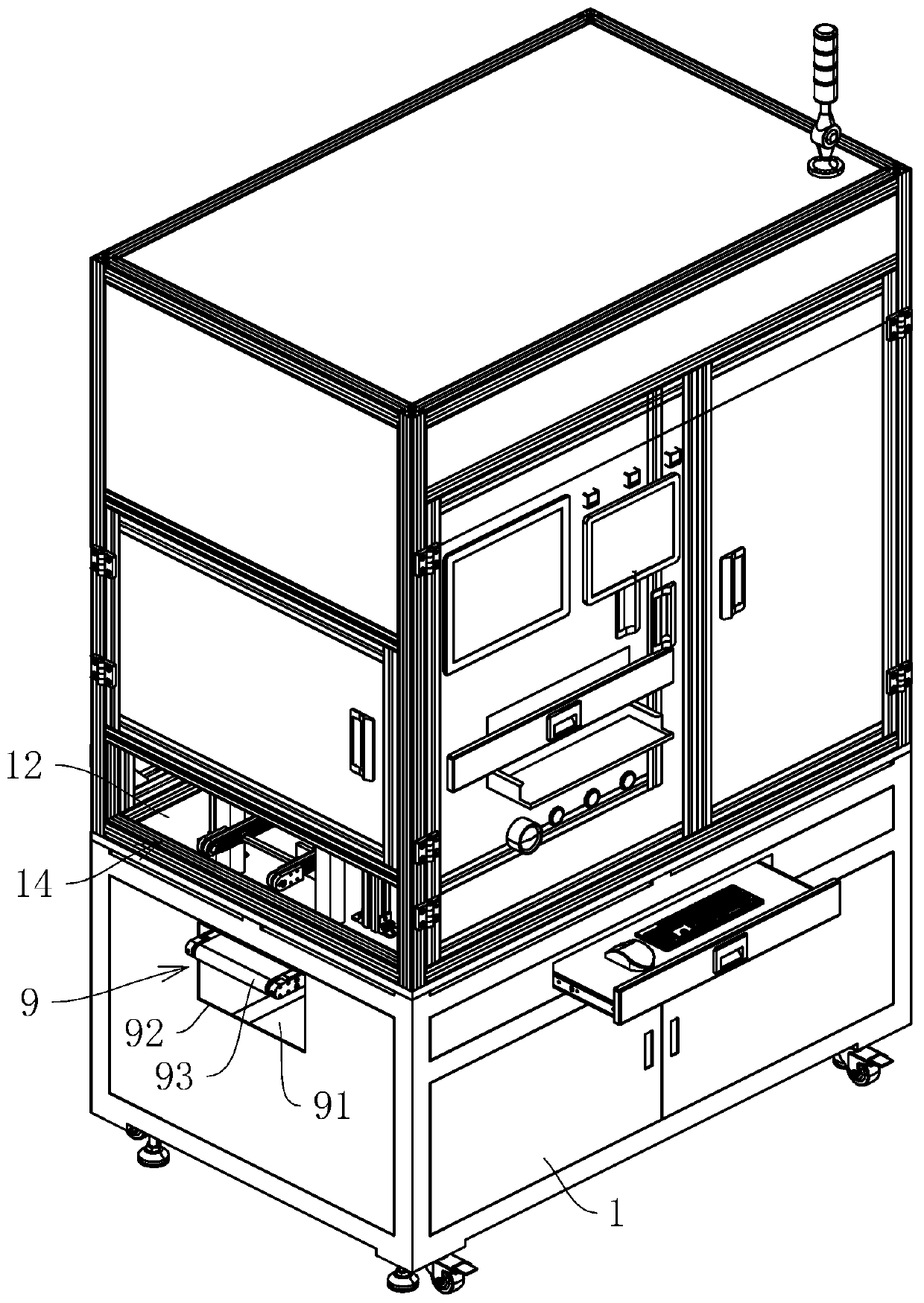

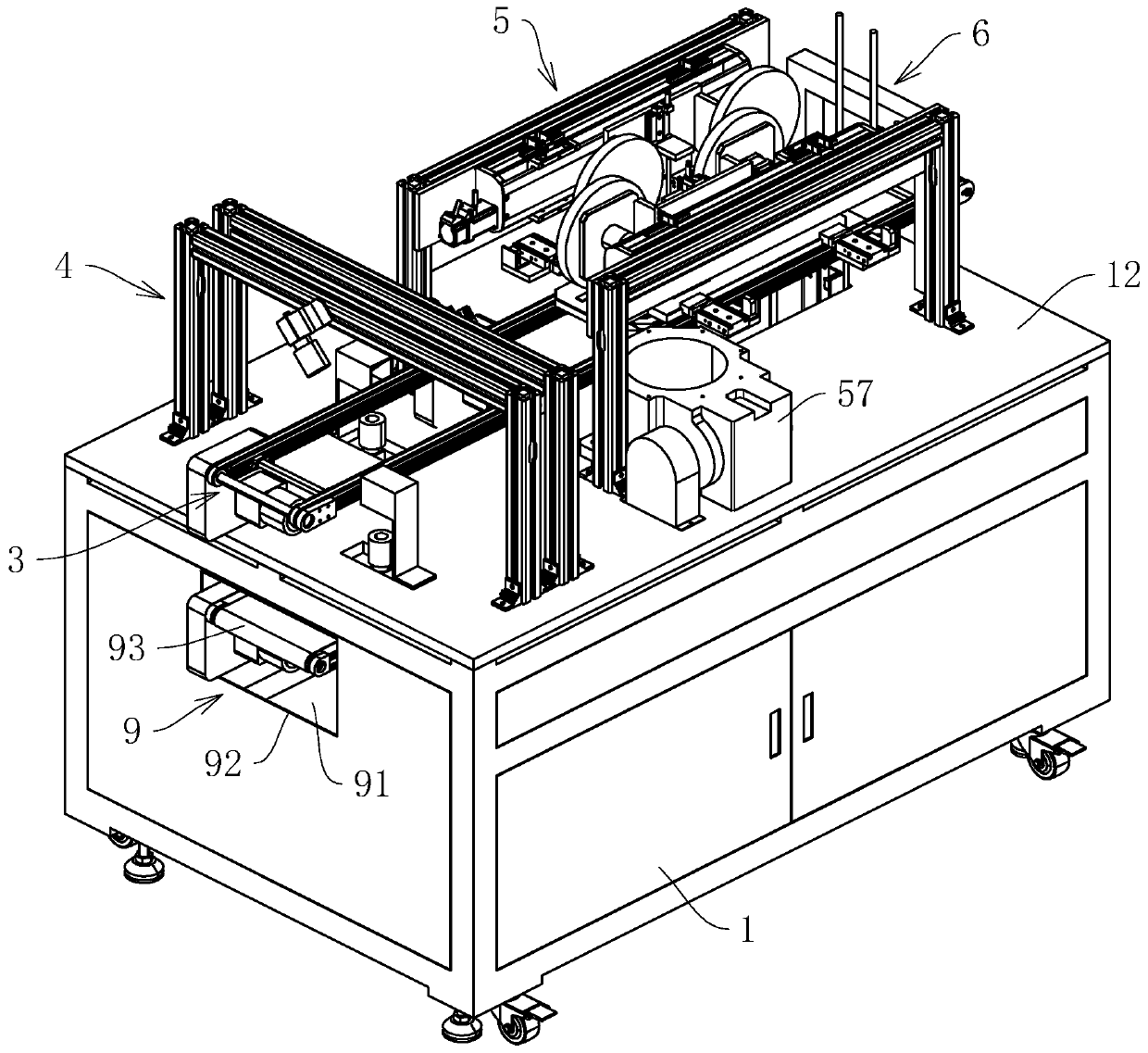

[0054] refer to figure 1 and figure 2 , is a PCB inspection and wiping all-in-one machine disclosed in the present invention, including a housing 1 and a workbench 12 horizontally arranged in the housing 1, the workbench 12 divides the inside of the housing 1 from top to bottom into a working chamber 11 And the installation cavity 91. One end of the housing 1 is provided with a material inlet 13 communicating with the working chamber 11 , and the other end of the housing 1 is provided with a material outlet 14 communicating with the working chamber 11 . The end of the housing 1 near the feed port 13 and the end near the discharge port 14 are both provided with a through port 92, and a return line 9 is provided in the installation cavity 91. Specifically, the return line 9 is provided in the installation cavity 91 The conveyor belt 93 is arranged along the direction from the feed port 13 to the discharge port 14, and both ends of the conveyor belt 93 protrude from the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com