Rotor iron core piece, rotor iron core, rotor, permanent magnet synchronous motor and related products

A rotor core and rotor iron technology, applied to synchronous motors with stationary armatures and rotating magnets, motors, magnetic circuits, etc., can solve the problems of increased cost and large amount of permanent magnets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

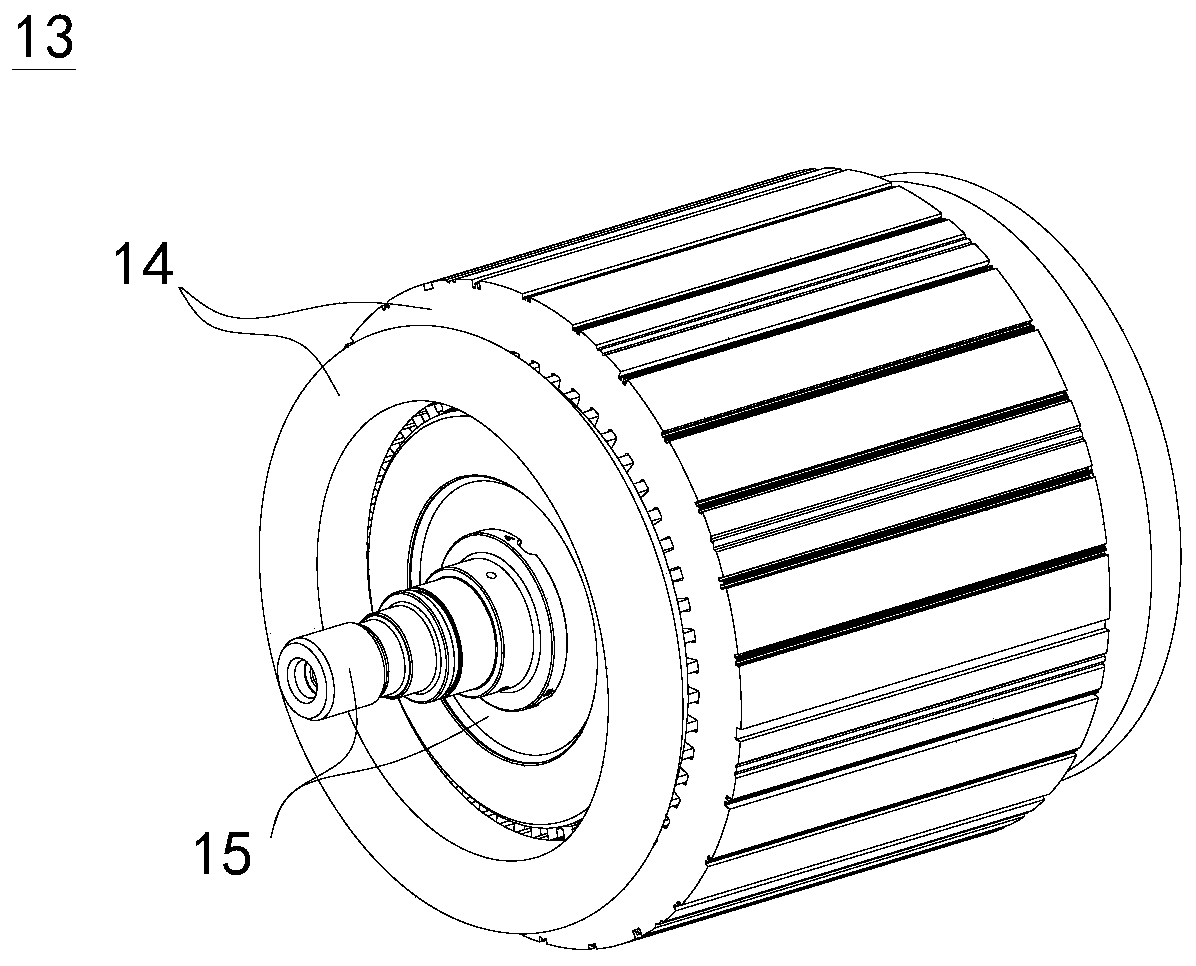

[0038] The embodiment of this application provides an electric vehicle, including but not limited to electric cars, electric buses, electric motorcycles, etc., for example figure 1 An electric SUV (Sport Utility Vehicle, sport utility vehicle) 10 is schematically shown. The electric vehicle 10 may include a frame and a powertrain mounted on the frame. Among them, the vehicle frame serves as the structural skeleton of the electric vehicle 10, and is used to support, fix and connect various assemblies, and bear loads from the interior of the vehicle system and from the external environment. A powertrain is a system of components used to generate and transmit power to the road. Such as figure 2 As shown, the powertrain 11 may include a motor controller 12 and a permanent magnet synchronous motor 13 . The motor controller 12 is electrically connected with the permanent magnet synchronous motor 13 and used for controlling the operation of the permanent magnet synchronous motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com