A kind of low-smoke halogen-free EPDM rubber composition and preparation method

A technology of EPDM rubber and its composition, which is applied in the field of flame retardants, can solve the problems of large impact on rubber mechanics and mechanical properties, easy precipitation of small organic molecule flame retardants, and large dosage of halogen-free flame retardants, etc., to achieve Excellent flame retardant performance, good char formation and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

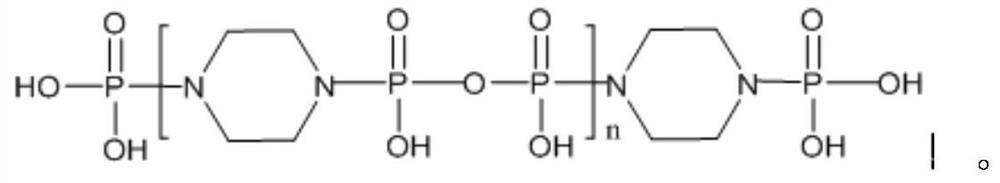

Method used

Image

Examples

Embodiment 1~9

[0046] According to the mass ratio of each component in Table 1 and the above-mentioned processing and preparation method, intumescent halogen-free flame retardant and flame retardant EPDM rubber material were prepared.

[0047] (1) Preparation of intumescent halogen-free flame retardants

[0048] Add the focus piperazine phosphate, hypophosphite and zinc borate in the intumescent flame retardant to the high-speed mixer according to the formula ratio of each component, control the stirring speed and stirring time, and ensure that the components are uniformly dispersed and mixed. The mixing time and speed are adjusted according to the actual operation of the high-speed mixer equipment.

[0049] (2) Preparation of flame retardant EPDM rubber

[0050] 1) adding a certain quality of EPDM rubber into the internal mixer for plasticizing, time 3min, rotating speed 50r / min, to obtain masterbatch;

[0051] 2) Add the corresponding quality of intumescent halogen-free flame retardant, ...

Embodiment 10~16

[0062] According to the mass ratio of each component in Table 2 and the above-mentioned processing and preparation method, an intumescent halogen-free flame retardant and a flame-retardant EPDM rubber material were prepared. In Examples 10 to 16, white carbon black, montmorillonite or silicon was added. One or a mixture of limestone fills and reinforces flame retardant EPDM rubber.

Embodiment 17

[0070] An intumescent halogen-free flame retardant, comprising the following components in parts by weight:

[0071] 85 parts of silane coupling agent modified focus piperazine phosphate;

[0072] 15 parts of zinc hypophosphite;

[0073] Zinc borate 5 parts.

[0074] Add the focused piperazine phosphate, hypophosphite and zinc borate to the high-speed mixer according to the formula ratio of each component. By controlling the stirring speed to 600r / min and the stirring time to 60min, ensure that the components are uniformly dispersed and mixed.

[0075] A low-smoke halogen-free EPDM rubber composition, the composition comprises the following components in parts by weight:

[0076]

[0077] The vulcanization aid is composed of the following components in parts by weight: 0.5 part of sulfur as vulcanizing agent, 0.5 part of sulfenamide vulcanization main accelerator CZ, 0.5 part of thiuram-type secondary accelerator TMTD, and 0.5 part of stearic acid as vulcanization active ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com