Production method of 2,3-dichloro-1-propene compound and production device of production method of 2,3-dichloro-1-propene compound

A dichloropropene and preparation device technology, applied in 2 fields, can solve problems such as low yield, high cost, and poor product quality, and achieve high yield, low cost, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

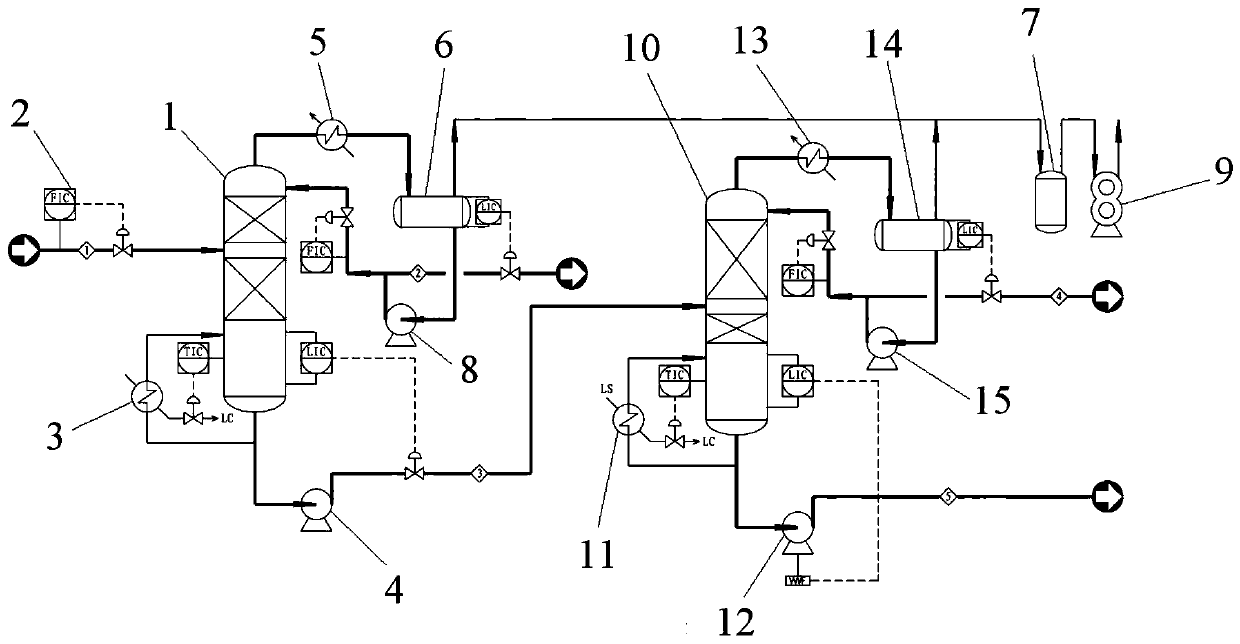

preparation example Construction

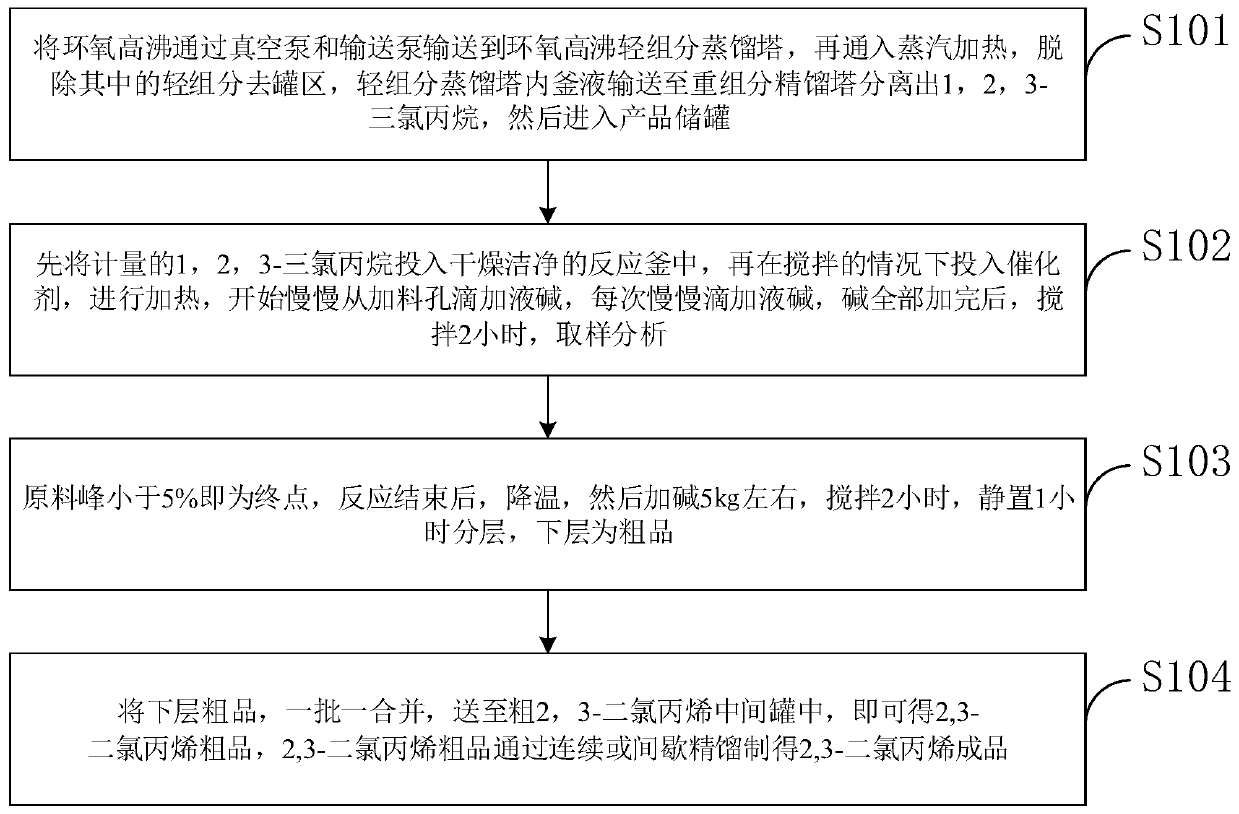

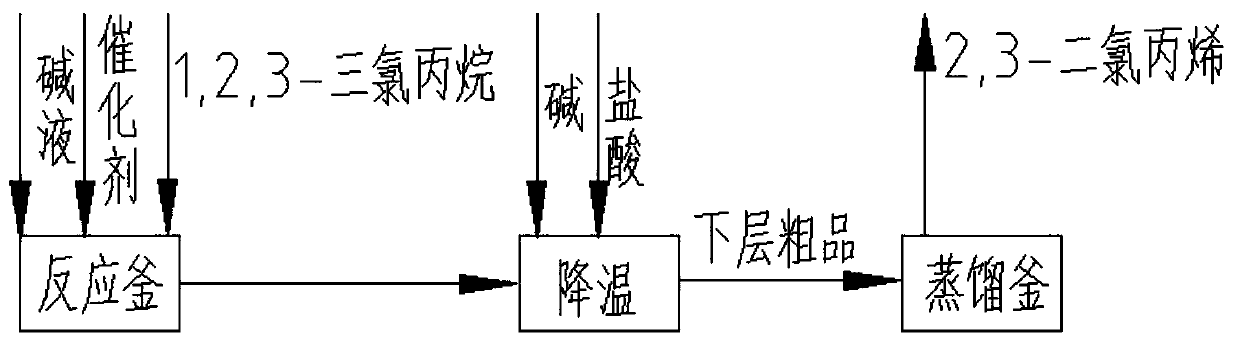

[0041] like figure 1 As shown, the preparation method of 2,3-dichloropropene compound provided by the embodiments of the present invention includes:

[0042] S101: Transport the epoxy high-boiler to the epoxy high-boiler light component distillation tower through a vacuum pump and a delivery pump, and then pass it into steam for heating, remove the light component and go to the tank area, and transport the still liquid in the light component distillation tower The 1,2,3-trichloropropane is separated from the heavy component rectification column, and then enters the product storage tank.

[0043] S102: First put the metered 1,2,3-trichloropropane into a dry and clean reaction kettle, then put in the catalyst while stirring, heat it, and start to slowly add liquid caustic soda from the feeding hole, slowly each time Add liquid caustic soda dropwise. After all the caustic soda is added, stir for 2 hours, and take samples for analysis.

[0044]S103: The peak of the raw material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com