Laboratory research device for coal and electricity integrated three-waste-based foaming material

A foaming material and laboratory technology, applied in the direction of mixed material pretreatment, transportation and packaging, chemical instruments and methods, etc., can solve problems such as single method, poor feasibility, and low comprehensive utilization of waste from coal-electricity integration. To achieve the effect of ensuring constant current or constant pressure supply, shortening foaming time and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

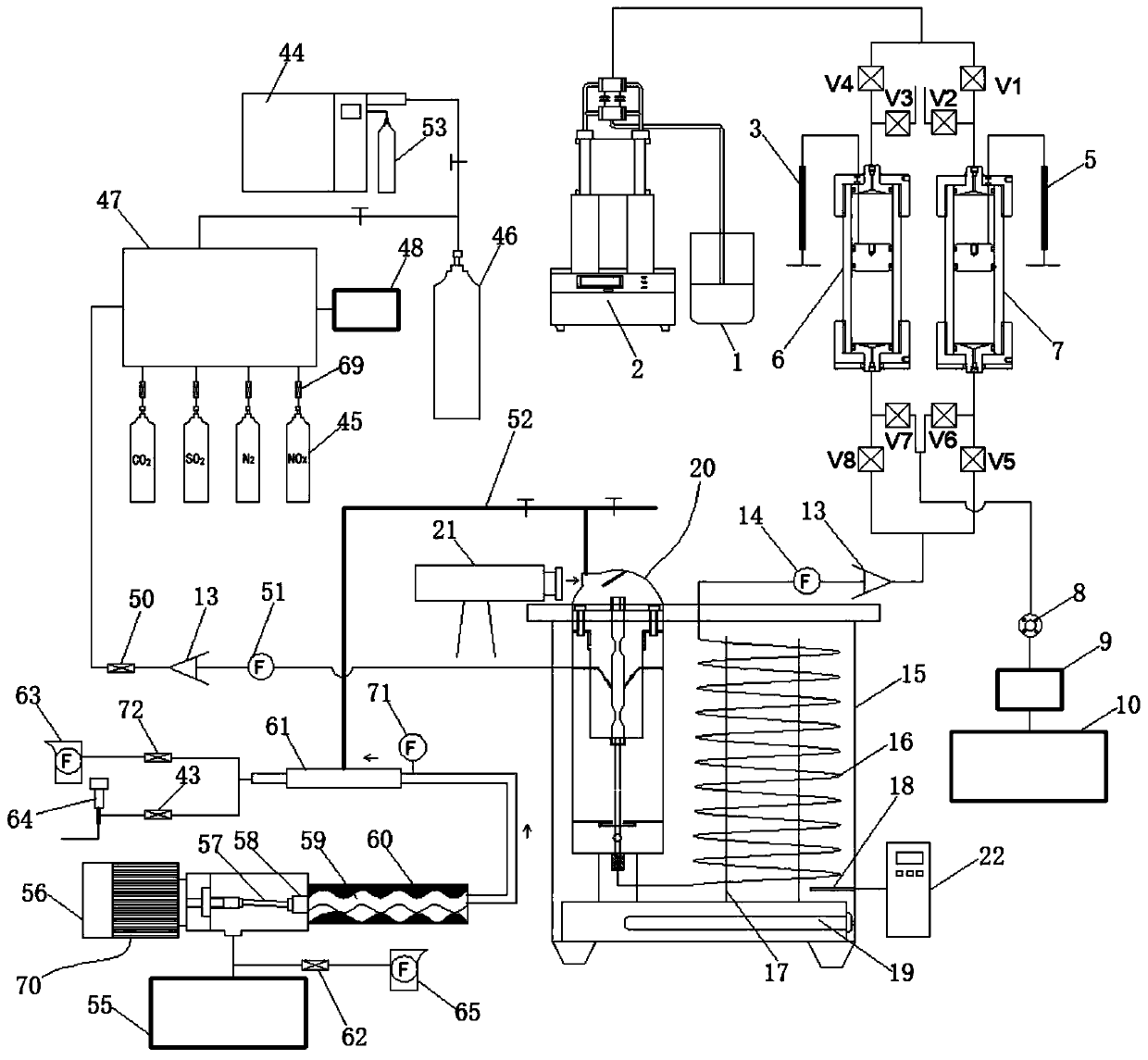

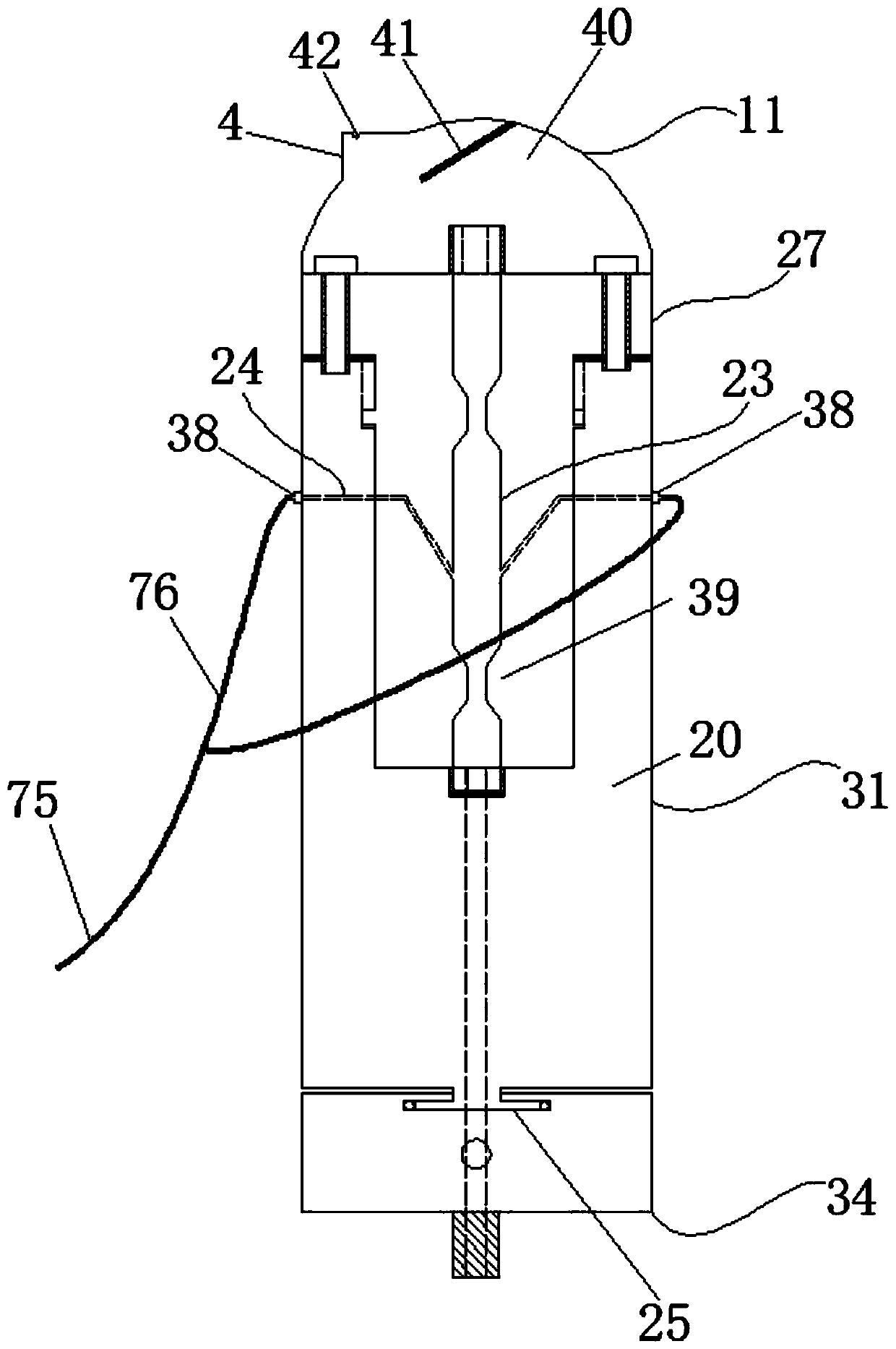

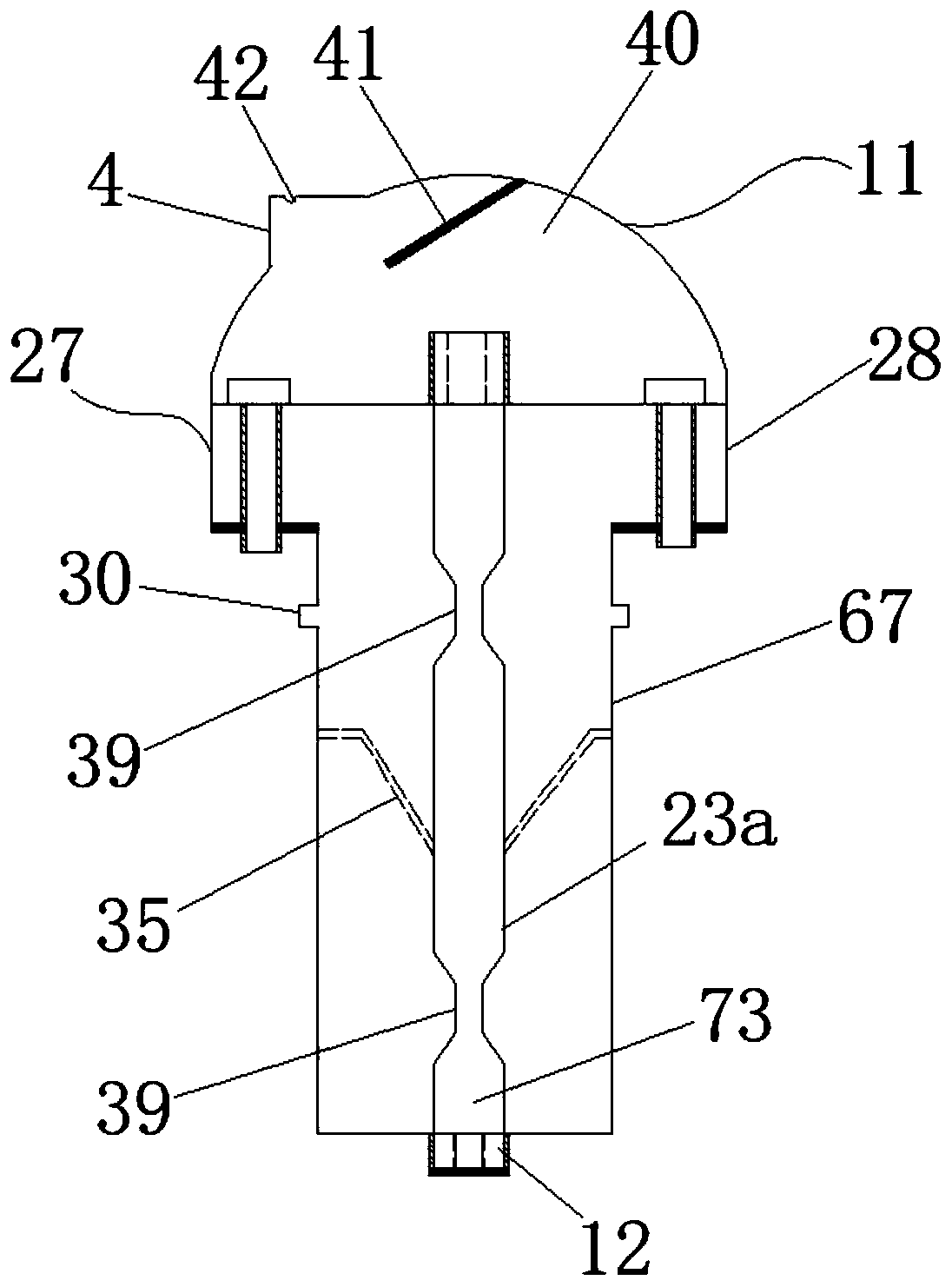

[0036] Such as figure 1 As shown, a laboratory research device for coal-electricity integration three-waste-based foaming material, including coal-electricity integration three-waste-based foaming material generation device, constant flow device for foaming agent mixed solution, foam generation and observation device, smoke Gas component analysis and gas distribution device and console; as a preference, the console is an industrial computer;

[0037] The constant flow device of the foaming agent mixed solution comprises a water-liquid mutual driving unit, a constant current and constant pressure pump 2 and a foaming agent solution mixing unit; the water-liquid mutual driving unit comprises a first two-way piston cylinder 6, a second two-way Piston cylinder 7 and a plurality of switching valves; The structure of the first two-way piston cylinder 6 and the second two-way pis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com