Electronic injection pen

An injection pen and electronic technology, applied in the field of medical supplies, can solve the problems of low precision, easy to puncture the skin by mistake, and inability to inject according to the curve (such as slow first, etc.), to achieve a reasonable structure layout and the effect of being easy to hold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

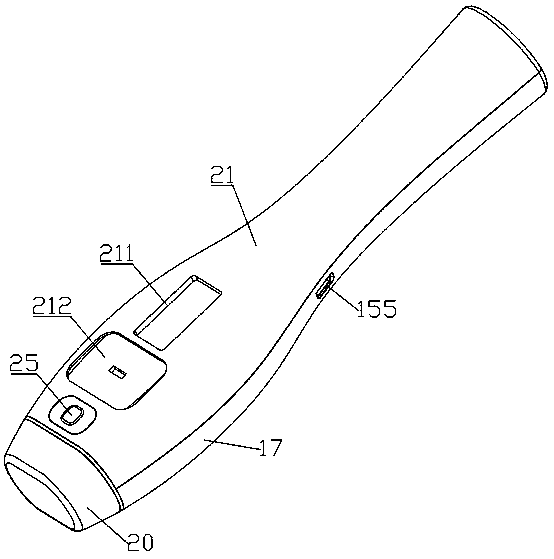

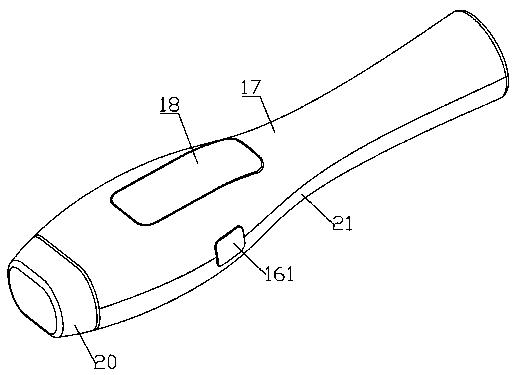

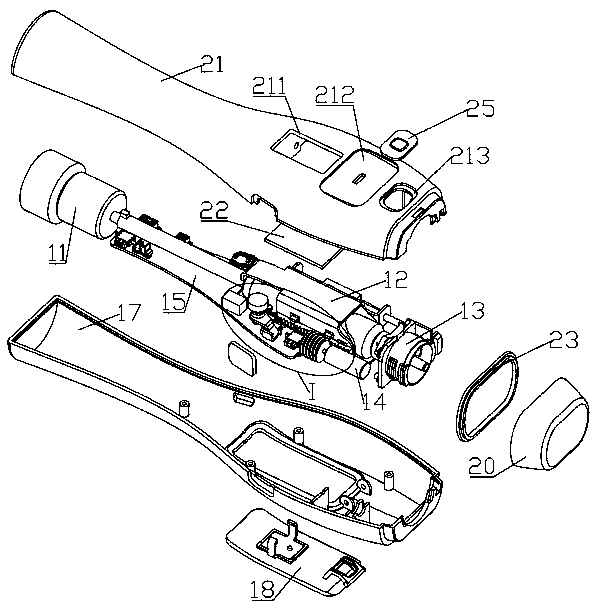

[0062] An electronic injection pen, such as Figure 1 to Figure 17 , including a pen case, a first driving mechanism 11, a liquid medicine cartridge assembly 12, a needle changing mechanism 13, a second driving mechanism 14, a sensing control unit 15, a bottle changing switch assembly 16, a display unit 22 and a battery unit 24, each mechanism , components and units are all installed in the inner cavity of the pen case, the needle exchange mechanism 13 is at the front end of the injection pen, the liquid medicine cartridge assembly 12 is at the rear side of the needle exchange mechanism 13, and the first driving mechanism 11 is at the side of the liquid medicine cartridge assembly 12 On the rear side, the battery unit 24 is located on the rear side of the first drive mechanism 11 and at the rear end of the electronic injection pen, the sensor control unit 15 is connected to the first drive mechanism 11, the second drive mechanism 14, the battery unit 24 and the display unit 22,...

Embodiment 2

[0121] In this embodiment, an electronic injection pen is provided. The first driving mechanism 11 of the electronic injection pen can adopt a linear motor or an electronic push rod, etc., and can adopt a method in which a non-exposed rotating screw rod cooperates with a linearly running screw sleeve. However, a linear stepping motor is used, that is, the exposed output shaft itself can move in a straight line, etc., as long as it can realize switching of at least two speeds.

[0122] For example, the first drive mechanism 11 includes a first motor, a screw and a threaded sleeve (nut), the output shaft of the first motor is connected to the threaded sleeve, the threaded sleeve has internal threads, and the screw is threaded on the threaded sleeve, the first motor As a stepping motor, a guide mechanism (such as a guide block or a guide groove) can be set to guide the screw so that the screw can move linearly under the action of the threaded sleeve. Other shapes, structures, and...

Embodiment 3

[0124] In this embodiment, an electronic injection pen is provided, see Figure 20 with Figure 21 , its second drive mechanism 14 includes a second motor 141, a lead screw 144 and a nut one 145, and the second motor 141 is a DC motor. The output shaft of the second motor is connected to the lead screw 144, and the lead screw 144 is screwed on the nut one 145. Specifically, the external thread on the lead screw 144 is screwed on the internal thread on the nut one 145, and the nut one 145 is fixedly mounted on the medicine On the support three 126 on the liquid cylinder assembly. One end of the nut one 145 fixed on the bracket three 126 has a protrusion, and the bracket three 126 is provided with a through hole at the fixing part for the protrusion to be engaged and fixed. A sensor triggering portion for triggering the sensors 2 and 3 protrudes from the bracket 3 126 .

[0125] The liquid medicine cartridge assembly includes a liquid medicine cartridge, a guide rod, a bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com