Intelligent electro-hydraulic lifting control device and intelligent electro-hydraulic lifting control method for paddy field agricultural machine

A control device and electro-hydraulic technology, which is applied to the hoisting device of agricultural machinery, agricultural machinery, and adjustment device, etc., can solve the problems of increasing labor intensity, affecting work efficiency, and difficult to control the slip rate, so as to achieve enhanced fuel economy, The device has a compact structure and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

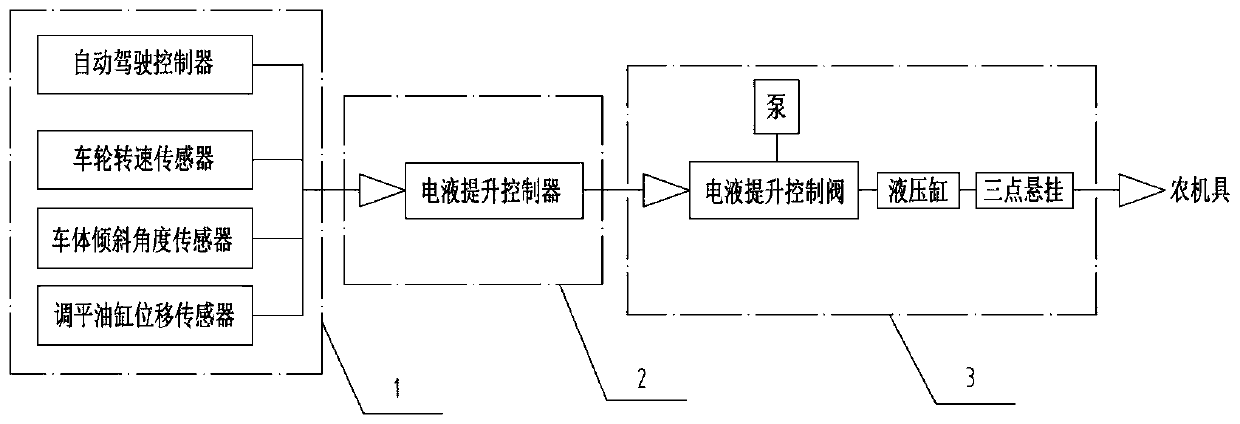

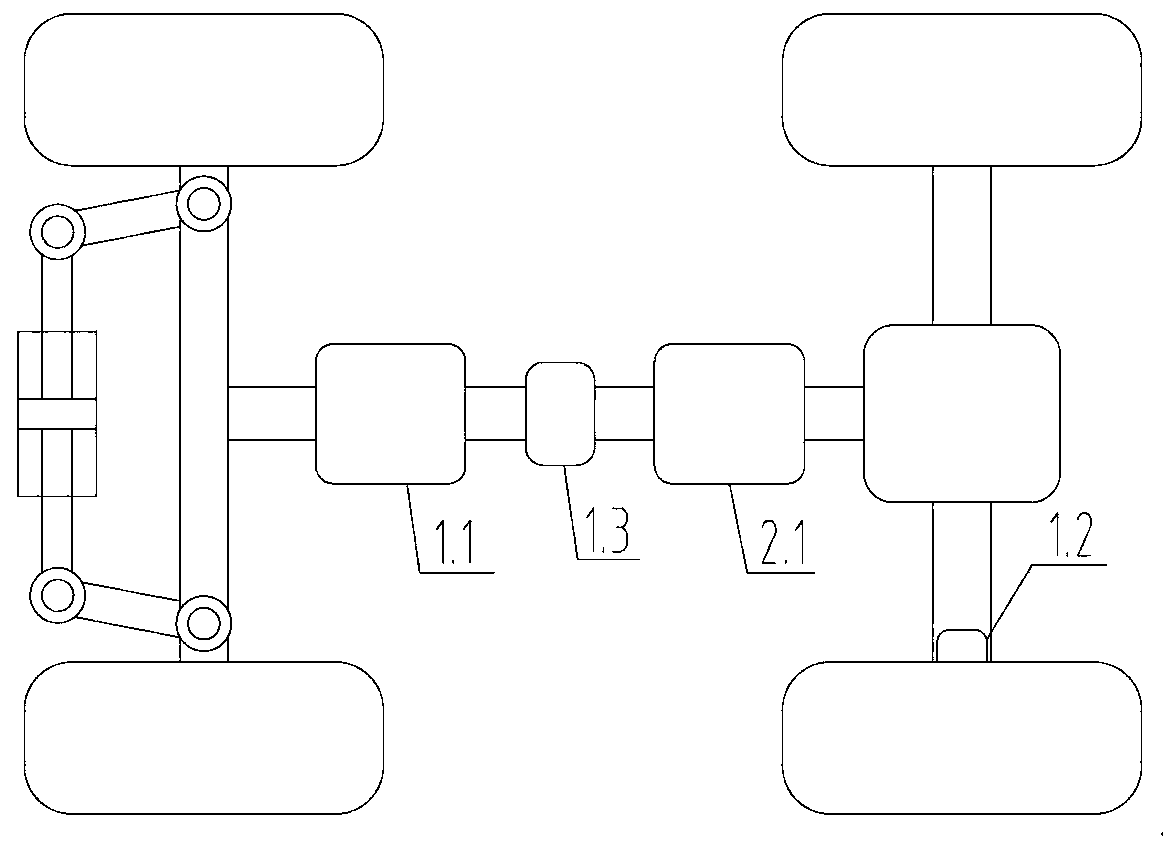

[0062] The slip rate of the agricultural machinery is controlled by the automatic driving controller 1.1 and the wheel speed sensor 1.2.

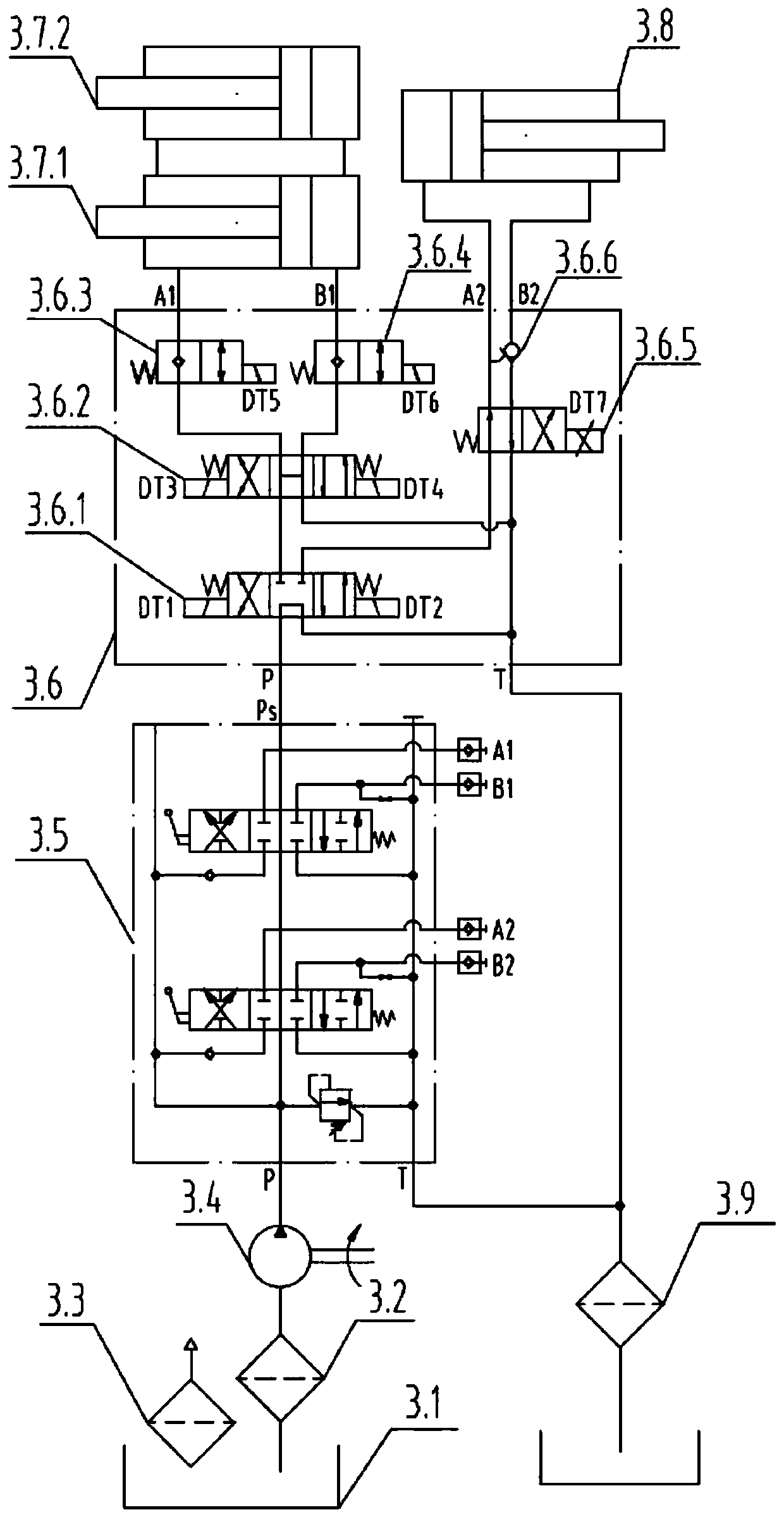

[0063] When the slip rate Sr is greater than 9%, lift the agricultural implements to reduce the plowing depth, and the direction of the oil circuit is the electro-hydraulic lifting controller 2.1 to control the first three-position four-way solenoid valve 3.6.1 to work in the right position (DT2 is energized), and the second No. 3-position, 4-way solenoid valve 3.6.2 works in the left position (DT3 is powered), No. 1, 2-position, 2-way solenoid valve 3.6.3 works in the right position (DT5 is powered), No. 2, 2-position, 2-way solenoid valve 3.6.4 The right position works (DT6 is energized); the pressure oil of the oil pump 3.4 enters the left lift cylinder 3.7.1 and the right lift cylinder 3.7.2 through the multi-way valve 3.5 middle position, each working position of the electro-hydraulic lift control valve block 3.6 and its B1 port Interc...

Embodiment 2

[0067] Utilize the automatic driving controller 1.1 to control the U-turn of the agricultural machinery.

[0068] In order to enable the tractor to automatically lift the agricultural implements to reduce load resistance when the tractor is working until the end of the field and turn around, and automatically lower the agricultural implements to restore the preset plowing depth to the straight line operation when the turn is completed.

[0069] In this technical solution, the automatic driving controller 1.1 outputs two state signals of turning around and working in a straight line to the electro-hydraulic lifting controller 2.1. When turning around and turning, the electro-hydraulic lifting controller 2.1 lifts the agricultural implement according to the preset lifting height; The electro-hydraulic lifting controller 2.1 lowers the agricultural implements according to the preset tillage depth. The direction of the oil passage is the same as that of Embodiment 1, and will not ...

Embodiment 3

[0073] The vehicle body inclination angle sensor 1.3 and the leveling oil cylinder displacement sensor 1.4 are used to realize the leveling of the agricultural machinery.

[0074] In order to be able to level the local uplift area of the paddy field well, so that the irrigation water can evenly cover each area. The technical solution realizes independent control of the left and right tilt angles of the agricultural machinery through a set of leveling mechanisms. Its working process is that the car body inclination angle sensor 1.3 detects the inclination angle of the car body in real time, the leveling oil cylinder displacement sensor 1.4 detects the displacement of the leveling oil cylinder 3.8 in real time, and the electro-hydraulic lifting controller 2.1 performs the displacement of the leveling oil cylinder 3.8 according to the car body inclination angle. Control to control the left and right inclination angle of the agricultural implement, because the left and right inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com