Rubber-tired track mine car traction device with offset compensation function

A technology of offset compensation and mine car traction, which is applied in traction devices, transportation and packaging, railway car body parts, etc., can solve problems such as swing compensation, achieve convenient disassembly and assembly, prevent lateral swing and derailment, and has a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

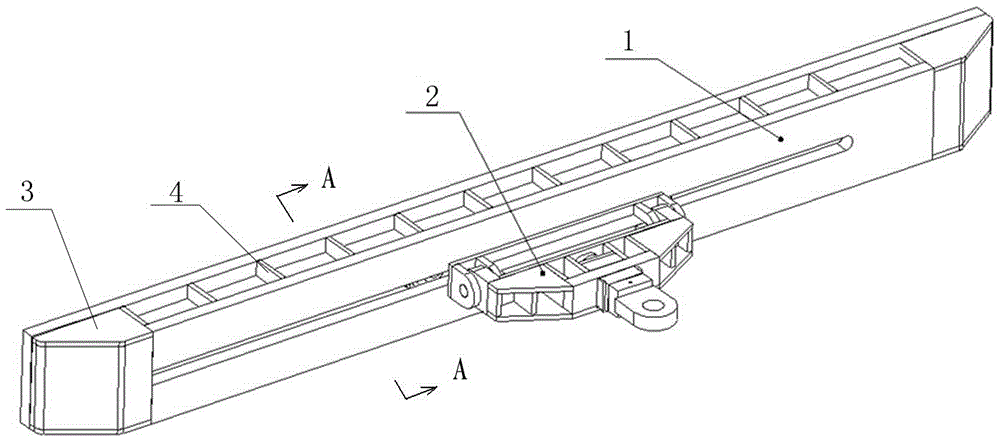

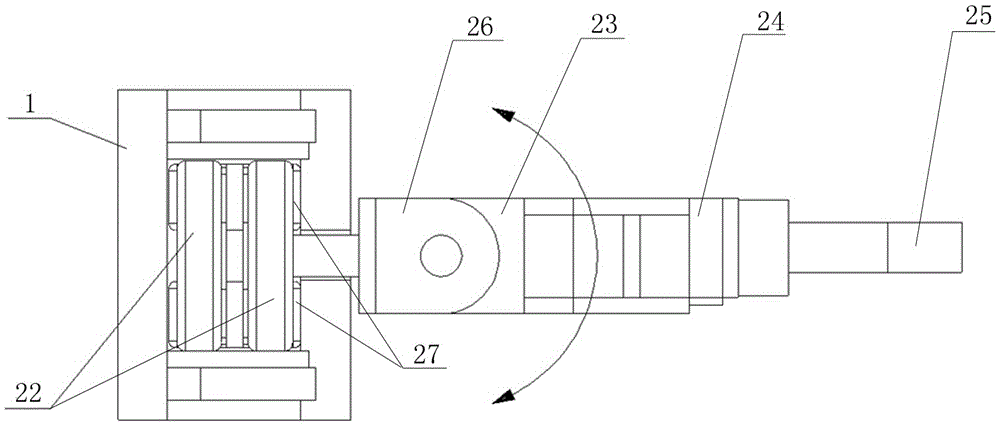

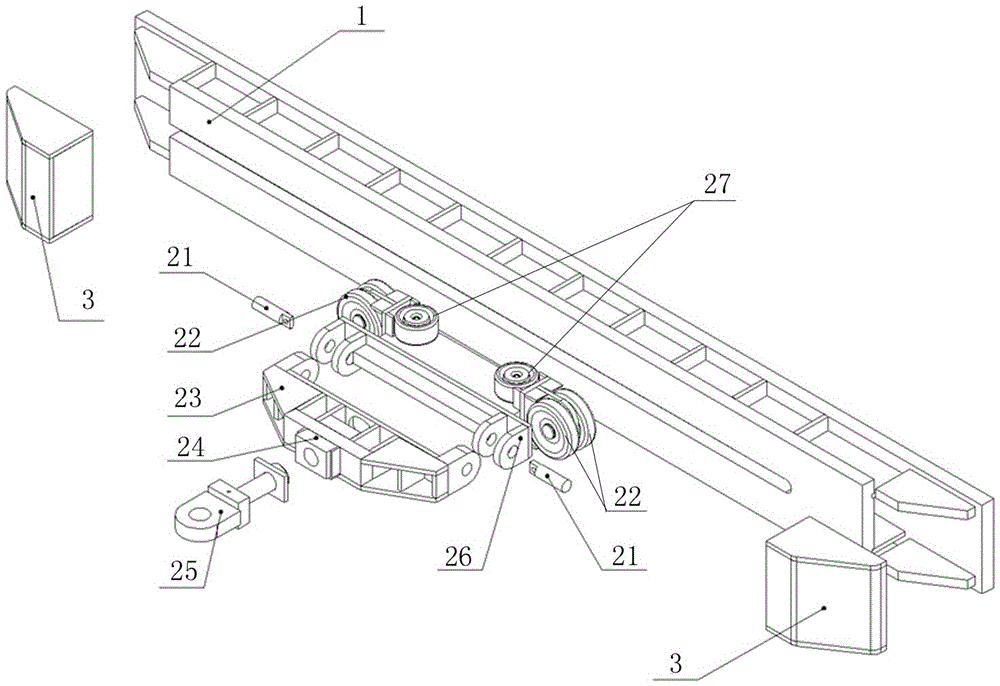

[0026] like figure 1 , 3 The shown rubber-wheeled rail mine car traction device with offset compensation function includes a slide rail 1 and a rail trolley 2, and the rail trolley 2 includes a guide wheel set, a wheel frame 26, a turret 23 and a traction member 25, and the guide The wheel group is connected with the wheel frame 26, and the guide wheel group is arranged in the rail groove of the slide rail 1, the wheel frame 26 and the turret 23 are connected by a pin shaft 21 arranged horizontally, and the turret 23 and the traction member 25 are connected and form a rotating pair .

[0027] The slide rail 1 is installed on the main frame of the rubber-tyred tractor. The front and rear plates adopt thick steel plates and are provided with reinforcing ribs. On the one hand, the bearing capacity is large, and on the other hand, welding deformation is preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com