A Production Scheduling Method for Flexible Job Shop Based on Particle Swarm Optimization

A particle swarm algorithm and flexible operation technology, applied in computing, computing models, artificial life, etc., can solve problems such as low efficiency and poor scheduling plan target values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

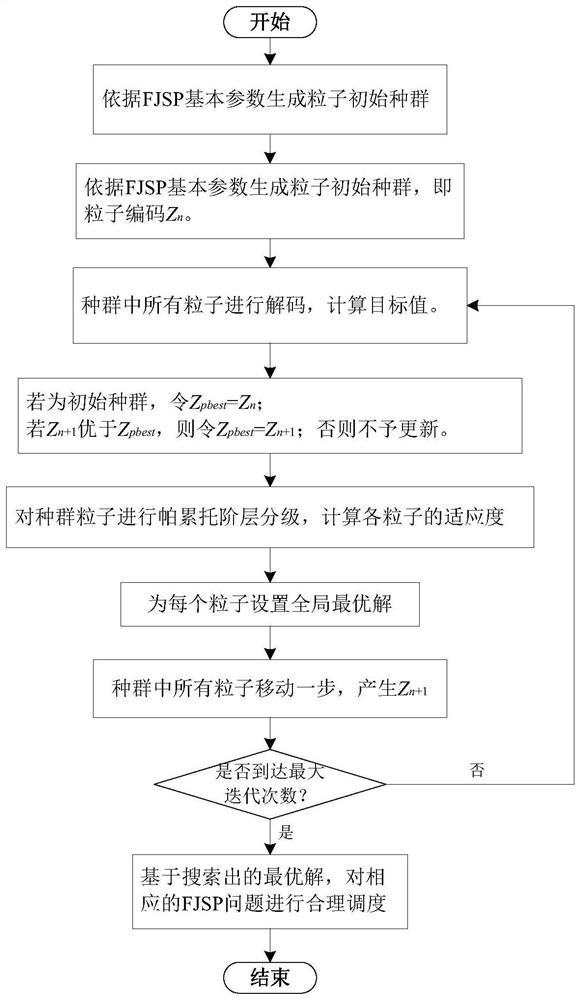

[0071] The implementation process of the present invention is as follows figure 1 shown, including the following steps:

[0072] Step 1: Based on the basic parameters of FJSP, an initial population of particles is generated, and the particles in the population generate initial spatial positions.

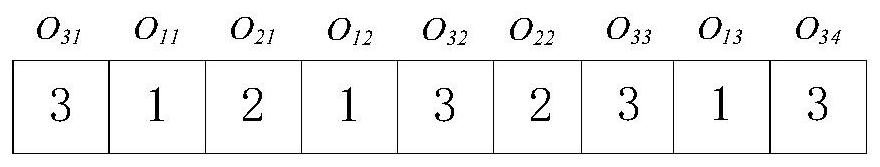

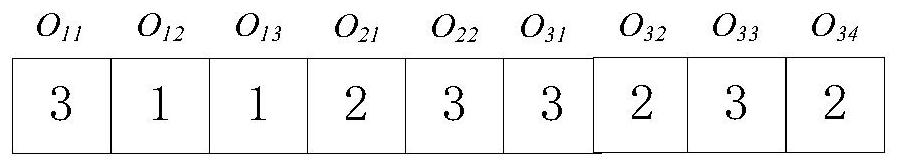

[0073] The FJSP problem can be described as: arrange n workpieces to be processed on m machines. Workpiece J i (1≤i≤n) includes n j a sequential process. Process O ij The processing time on machine k (1≤k≤m) is recorded as P ijk . Process O can be executed in m machines ij The set of machines is denoted as M ij . The FJSP problem is to assign all the operations to the appropriate machines and to determine the start and finish times of the operations. Table 1 is an example of FJSP, which describes the processing time of 3 workpieces on 3 machines. "—" indicates that a certain procedure cannot be processed on the corresponding machine.

[0074] Table 1 Examples of FJSP quest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com