Intelligent control device and method for concrete manual vibration fluctuation

A technology of intelligent control and control method, which is applied to the analysis of solids, buildings, and building structures using sound waves/ultrasonic waves/infrasonic waves. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

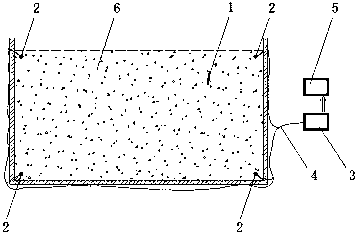

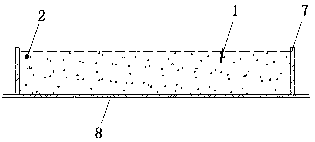

[0018] Example. An intelligent control device for artificial vibration of concrete, which is composed of figure 1 and 2 As shown, it includes a vibration signal sensor 2 for receiving the vibration signal of the vibrator 1, the vibration signal sensor 2 is connected to the acoustic wave instrument 3, and the acoustic wave instrument 3 is connected to the system 5 for collecting and processing the wave signal. Between the vibration signal sensor 2 and the acoustic wave instrument 3, and the acoustic wave instrument 3 and the acquisition and fluctuation signal processing system 5 can be connected by a wire 4 (such as figure 1 As shown), it can also be connected through the wireless network module, which can be selected according to actual needs.

[0019] The aforementioned vibration signal sensors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com