Double-sealing structure

A self-sealing structure, double-sealing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of leakage, insufficient sealing reliability, endangering the safe operation of the system, etc., and achieve the effect of improving the sealing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

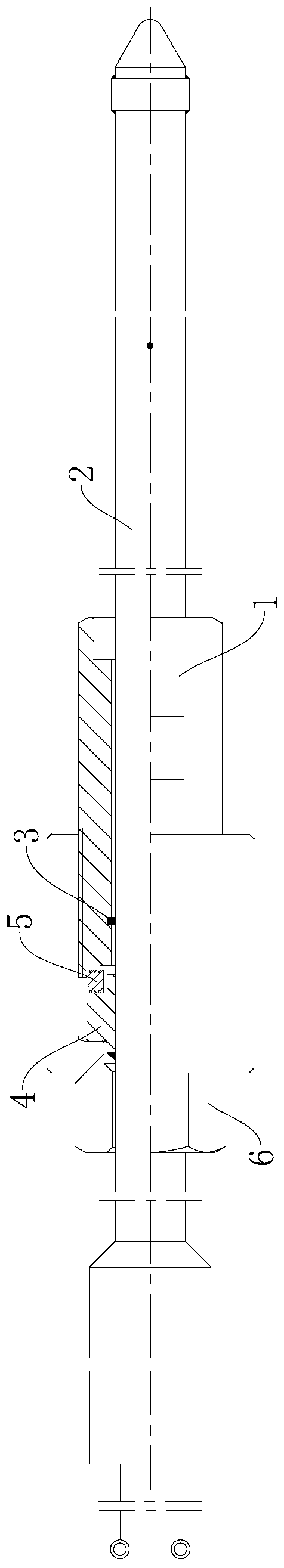

[0032] refer to figure 1 , the present invention provides a technical solution: a double sealing structure, including a self-sealing structure and a forced sealing structure, the self-sealing structure includes a sealing seat 1, a penetrating member 2 and an O-shaped rubber ring 3, and the inner sealing seat 1 There is a first groove, and the right angles of the first groove are rounded, and the rounded corners can effectively prevent the O-shaped rubber ring 3 from being scratched during compression deformation. The O-shaped rubber ring 3 is set In the first groove, the penetrating member 2 penetrates the sealing seat 1 and cooperates with the sealing seat 1, and the O-shaped rubber ring 3 provided in the sealing seat 1 is compressed to deformation by the penetrating member 2 , the self-sealing is achieved through the size fit between the through-piece 2 and the first groove in the sealing seat 1, and compresses the O-shaped rubber ring 3 arranged in the first groove to defor...

Embodiment 2

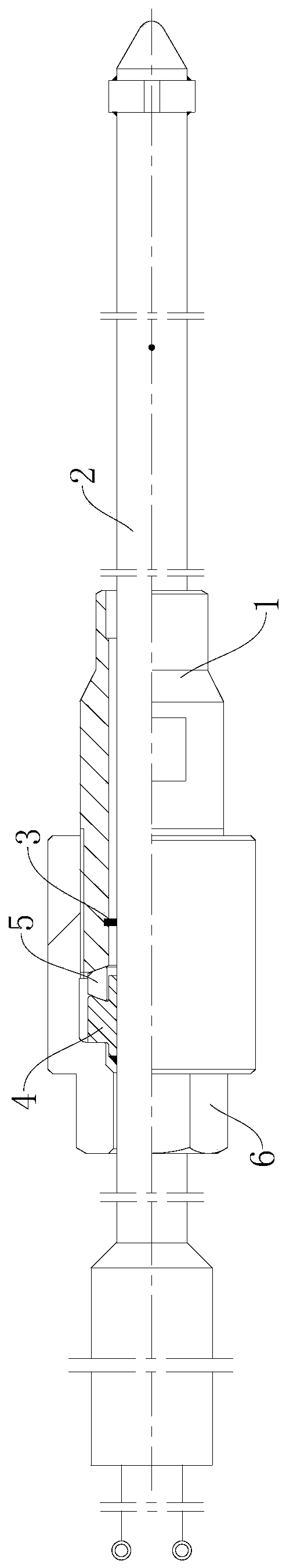

[0037] refer to figure 2 , the present invention provides a technical solution: a double sealing structure, including a self-sealing structure and a forced sealing structure, the self-sealing structure includes a sealing seat 1, a penetrating member 2 and an O-shaped rubber ring 3, and the inner sealing seat 1 There is a first groove, and the right angles of the first groove are rounded, and the rounded corners can effectively prevent the O-shaped rubber ring 3 from being scratched during compression deformation. The O-shaped rubber ring 3 is set In the first groove, the penetrating member 2 penetrates the sealing seat 1 and cooperates with the sealing seat 1, and the O-shaped rubber ring 3 provided in the sealing seat 1 is compressed to deformation by the penetrating member 2 , the self-sealing is achieved through the size fit between the through-piece 2 and the first groove in the sealing seat 1, and compresses the O-shaped rubber ring 3 arranged in the first groove to defo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com