Damping machine base for mounting electromechanical equipment

A technology for electromechanical equipment and installation, which is applied in the field of shock-absorbing bases for installation of electromechanical equipment, can solve the problems of poor shock-absorbing effect of shock-absorbing bases, and achieve the effects of improving shock-absorbing effect, improving fluency, and reducing frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

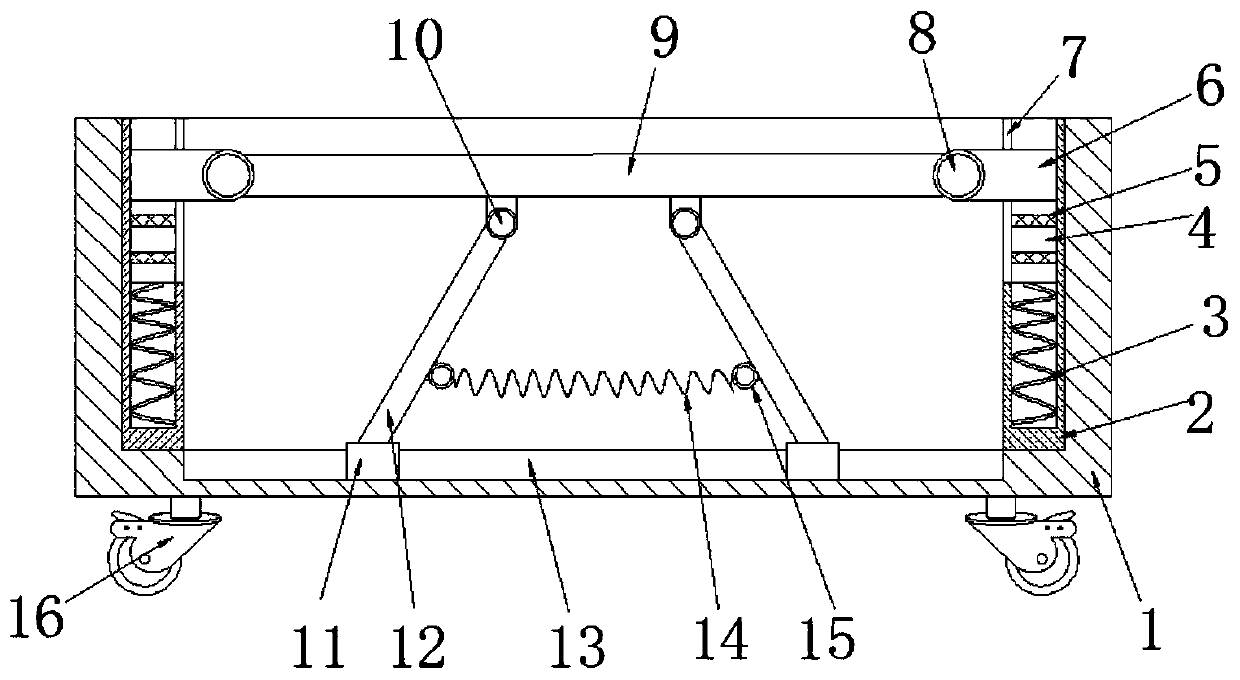

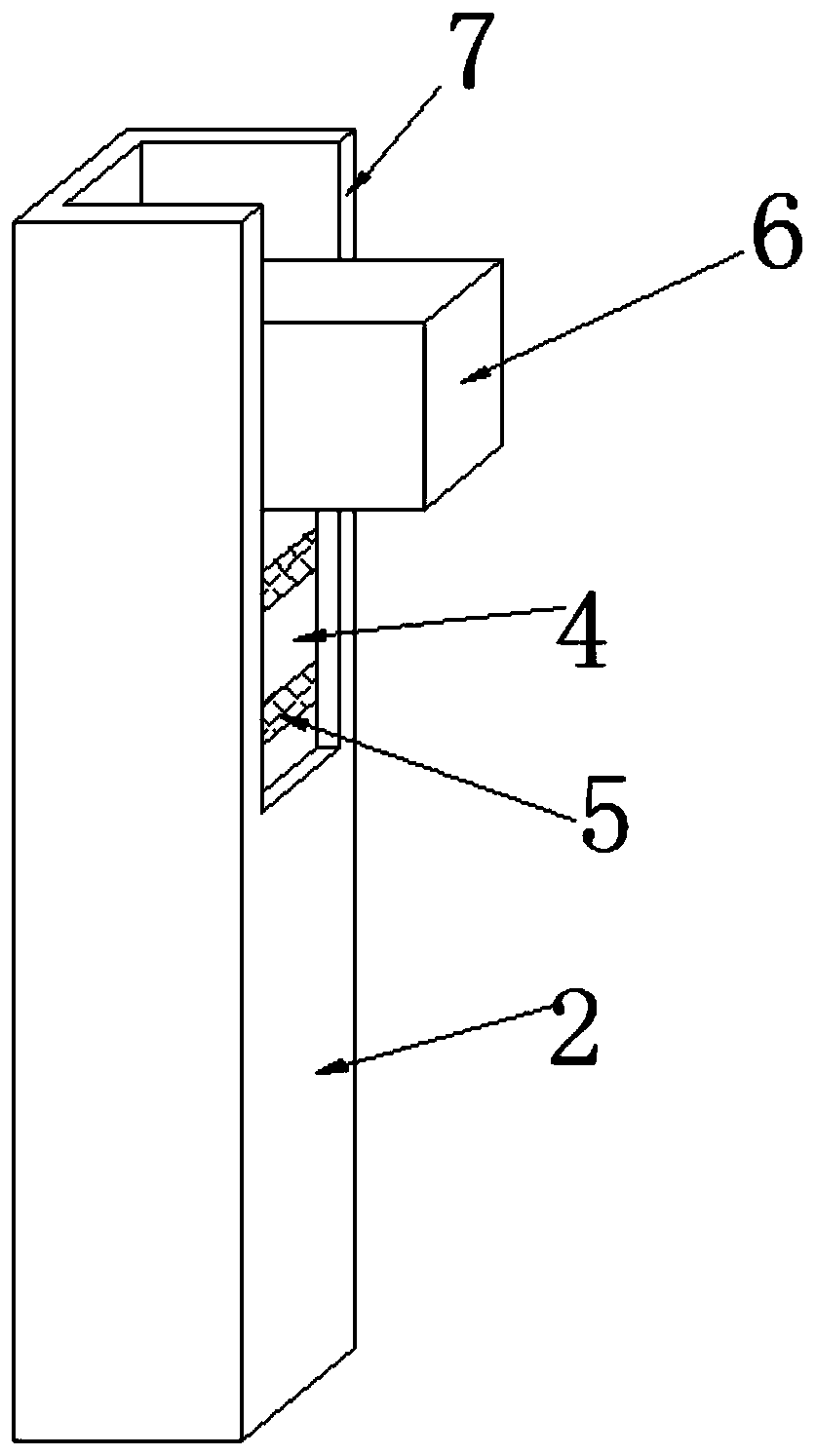

[0025] refer to figure 1 and figure 2 , a shock-absorbing machine base for installing electromechanical equipment, including a box body 1, a casing 2 is fixed at four corners inside the box body 1, and a support spring 3 is fixed inside the casing 2, and the outer wall of the casing 2 is opened. There is a movable port 7, a piston 4 is movably inserted in the casing 2, and a plurality of annular grooves are opened on the piston 4, and a rubber ring 5 that fits the inner wall of the casing 2 is embedded in the annular groove, and the top of the piston 4 is fixed. There are sliders 6 that form snap fit with the movable opening 7, and one end of the four sliders 6 is fixed with connecting ears 8, and the same storage board 9 is fixed between the connecting ears 8, and the outer wall of the bottom of the storage board 9 is fixed with two symmetrical Distributed shaft sleeves 10, support rods 12 are rotatably inserted in the shaft sleeves 10, and a reset mechanism is fixed betwee...

Embodiment 2

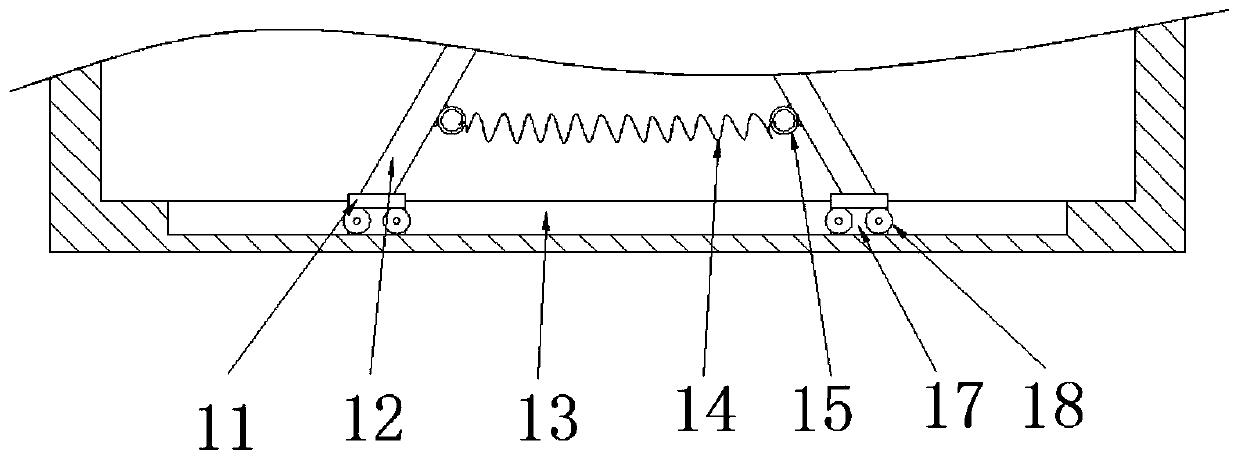

[0029] refer to image 3 , a shock-absorbing machine base for installing electromechanical equipment. The difference between this embodiment and Embodiment 1 is that the outer wall of the bottom of the guide block 11 also has a rolling groove 17, and a roller 18 is installed in the rolling groove 17 for rotation.

[0030] The working principle of this embodiment: the roller 18 can reduce the frictional resistance between the guide block 11 and the guide groove 13 and improve the smoothness of the movement of the guide block 11 .

Embodiment 3

[0032] refer to Figure 4 , a shock-absorbing machine base for installing electromechanical equipment. The difference between this embodiment and Embodiment 1 is that two symmetrically distributed clamping plates 19 are fixed on the outer wall of the top of the storage plate 9, and the clamping surface of the clamping plate 19 is fixed with Clamping pad 20 .

[0033] The working principle of this embodiment: two clamping plates 19 can be used to clamp the two sides of the electromechanical equipment body installed on the storage plate 9, and the clamping pad 20 can play an anti-slip protection effect on the outer wall surface of the electromechanical equipment body, improving The stability of clamping work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com