Method for controlling fuel metering system

A technology of fuel metering and fuel temperature, which is applied in the direction of charging system, electrical control, fuel injection pump, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

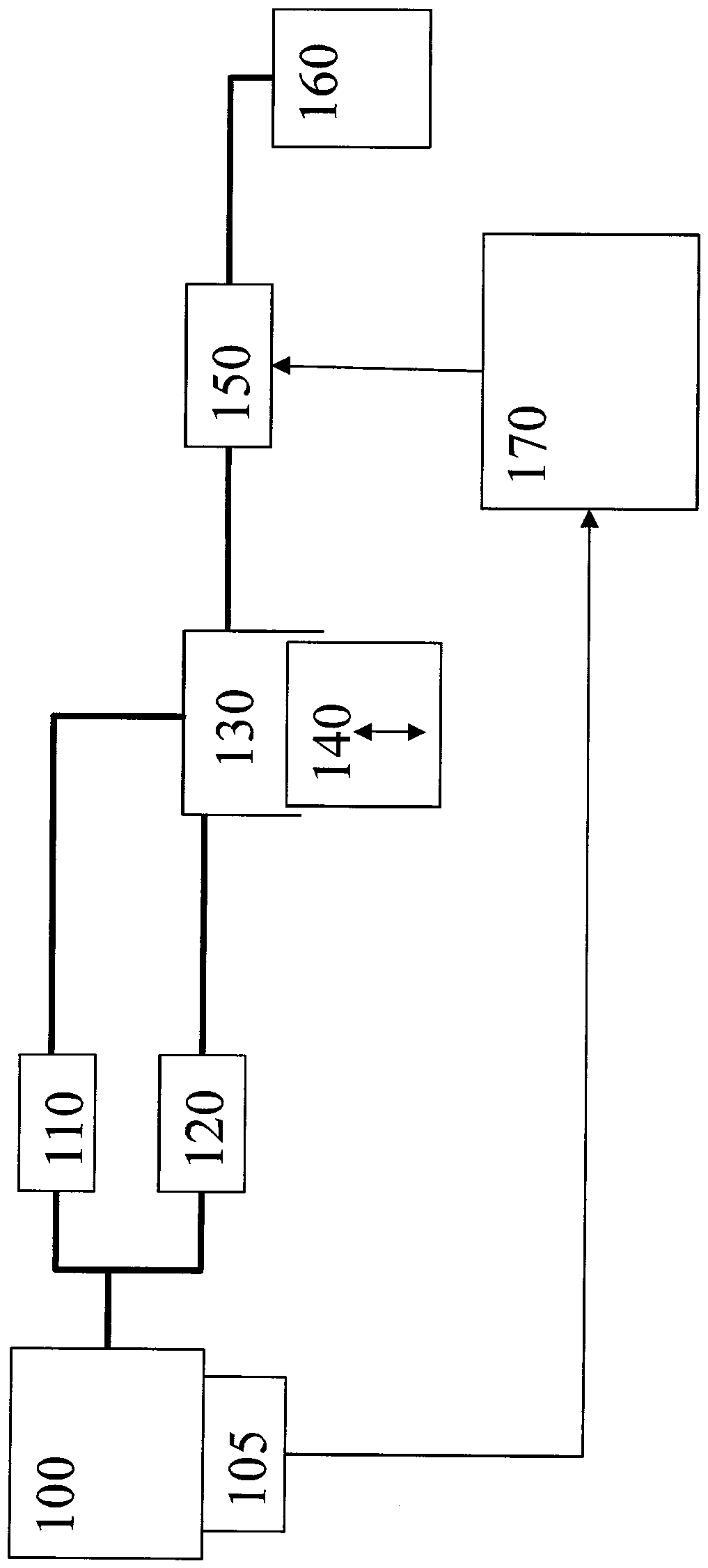

[0011] figure 1 The main elements of a fuel metering system of a fuel supply system of an internal combustion engine are shown. Use 100 to represent rails. Fuel passes from this rail 100 via injectors (not shown) into the combustion chamber of the internal combustion engine. The pressure P in the rail 100 , also referred to as rail pressure, is detected by the sensor 105 . The rail 100 is connected via a pressure limiting valve 110 and an outlet valve 120 to a delivery chamber 130 , ie a high-pressure pump. The fuel in delivery chamber 130 is compressed by piston 140 . For this purpose, the piston is driven by a drive unit from the camshaft or crankshaft of the internal combustion engine and expands and contracts the delivery chamber 130 by moving it back and forth.

[0012] Pressure limiting valve 110 is designed such that it releases the connection between the rail and delivery chamber 130 when the pressure in rail 100 exceeds a certain threshold value. Outlet valve 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com