Outer yarn rack device for automatically changing yarns

A creel, automatic technology, applied in the direction of piecing device, spinning machine, continuous winding spinning machine, etc., can solve the problems of human injury, personal safety hazards of staff, etc., to avoid safety hazards, realize full automation, The effect of increasing automation penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

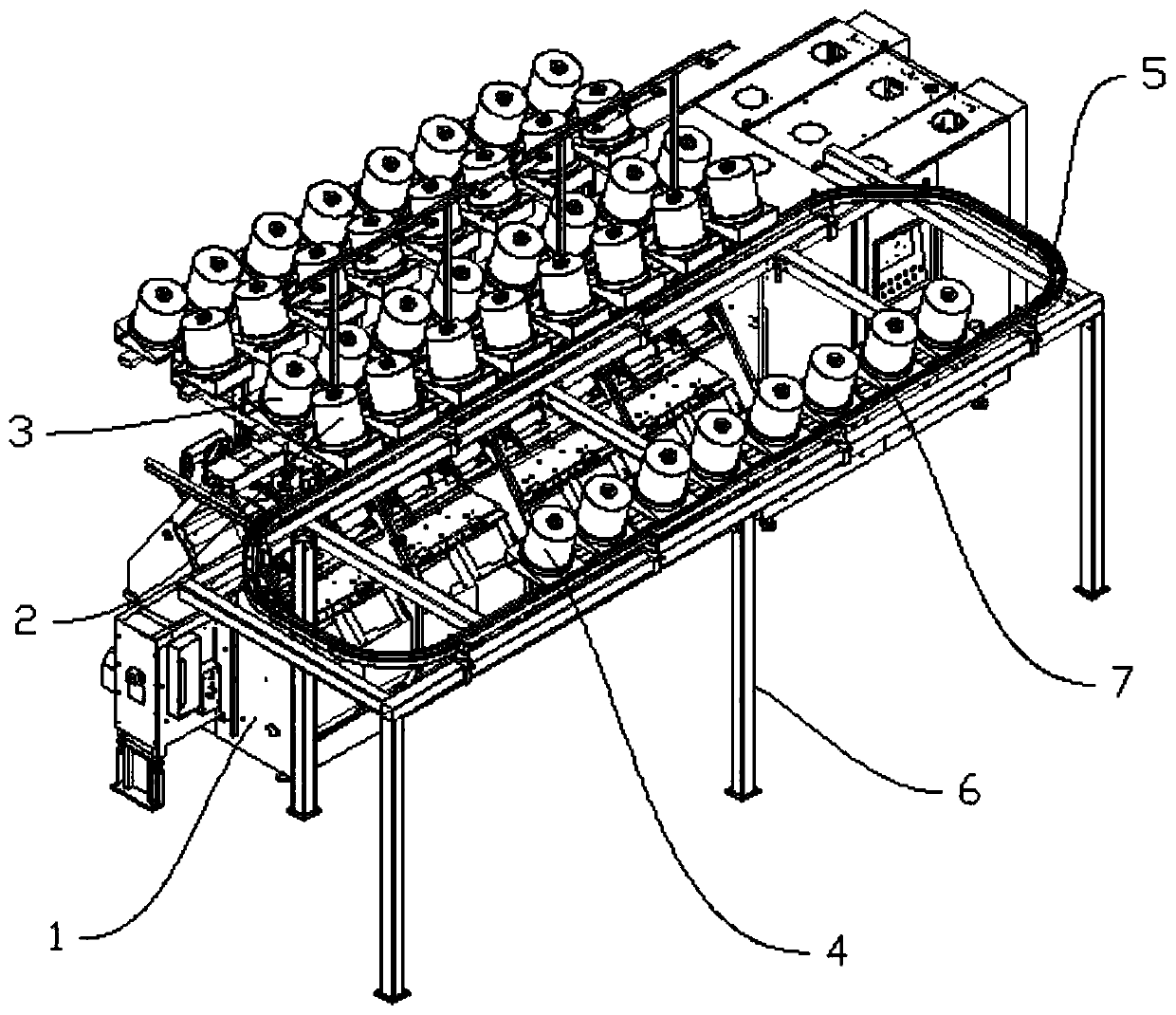

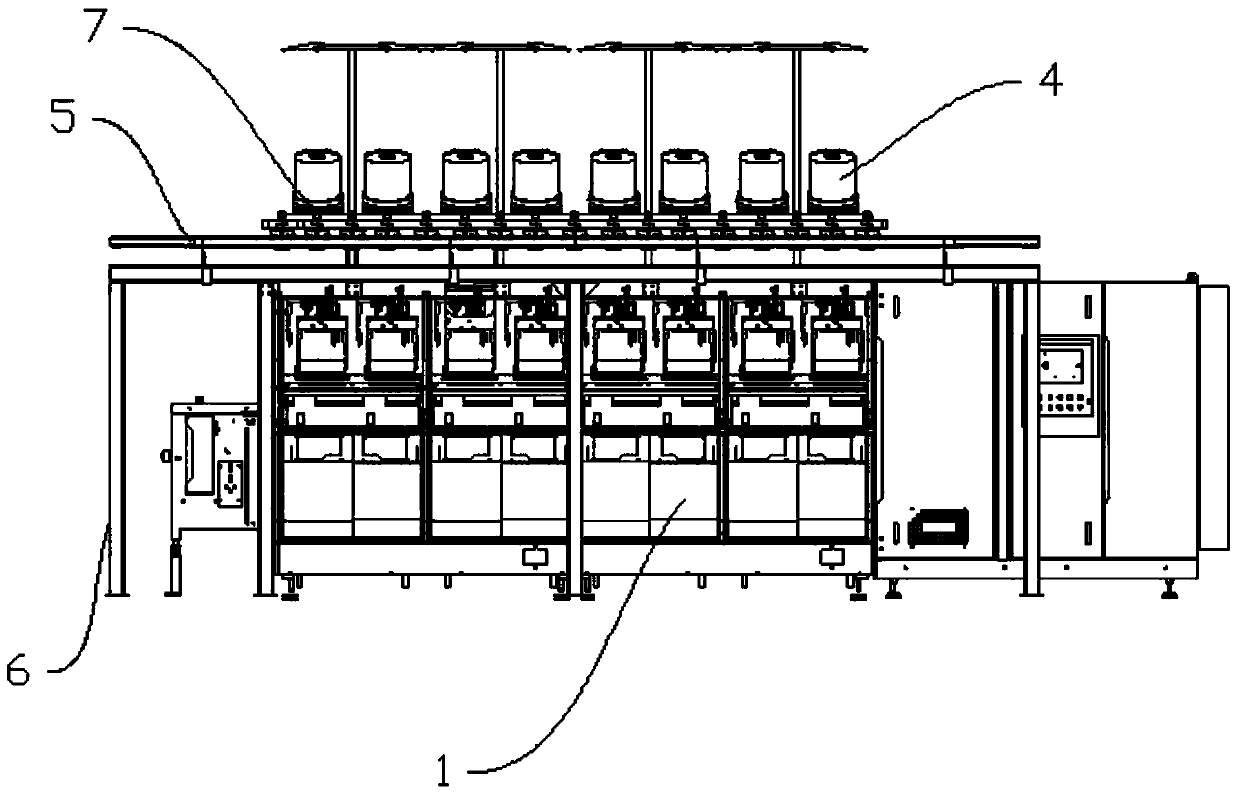

[0028] Such as Figure 1-4 As shown, the present invention proposes an outer creel device for automatic yarn change. The outer creel device of the present invention is used in conjunction with the main machine 1 that needs to be loaded with yarn. Several yarn feeding mechanisms are arranged side by side, and each yarn feeding mechanism includes two outgoing yarn reels 2 and a discharge spindle, wherein the two yarn reels 2 are arranged up and down, and the discharge spindle is arranged in the middle of the two yarn reels 2, Thereby saving space. The yarn reels 2 positioned above in each yarn feeding mechanism on the top of the main frame 1 have just formed a row of yarn reels 2 arranged in a straight line. And because each yarn roll 2 is provided with a spare yarn roll 3, then the top of the main frame 1 also has a row of spare yarn rolls 3 arranged side by side with the original yarn roll 2. In this embodiment, the main machine 1 includes yarn feeding mechanisms arranged si...

Embodiment 2

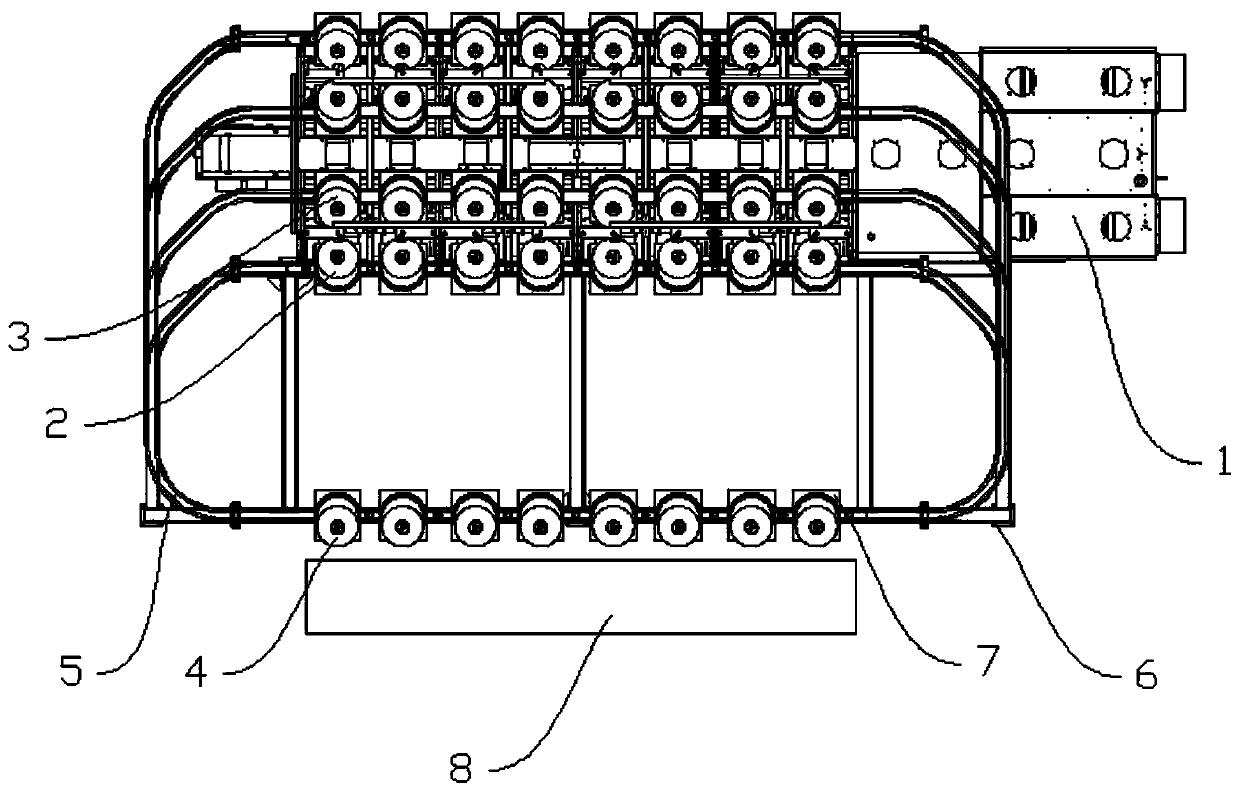

[0038] Such as Figure 5 As shown, the remaining parts in this embodiment are the same as in Embodiment 1, the difference is that the guide rail 5 exists between the different main machines 1 arranged in parallel, and corresponds to the yarn roll 2 and the spare yarn on each main machine 1. The guide rail 5 of roll 3 is bent and merged in the same direction at both ends to form a plurality of partially overlapping annular structures, so that all the main machines 1 in the factory can be simultaneously replaced by yarn roll 2 to further improve efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com