Sucking and throwing separated type steering granary flattening robot

A robot and steering device technology, applied in the field of warehouse closing robots, can solve problems such as poor working environment, inability to meet the use requirements, and inability to give full play to the advantages of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

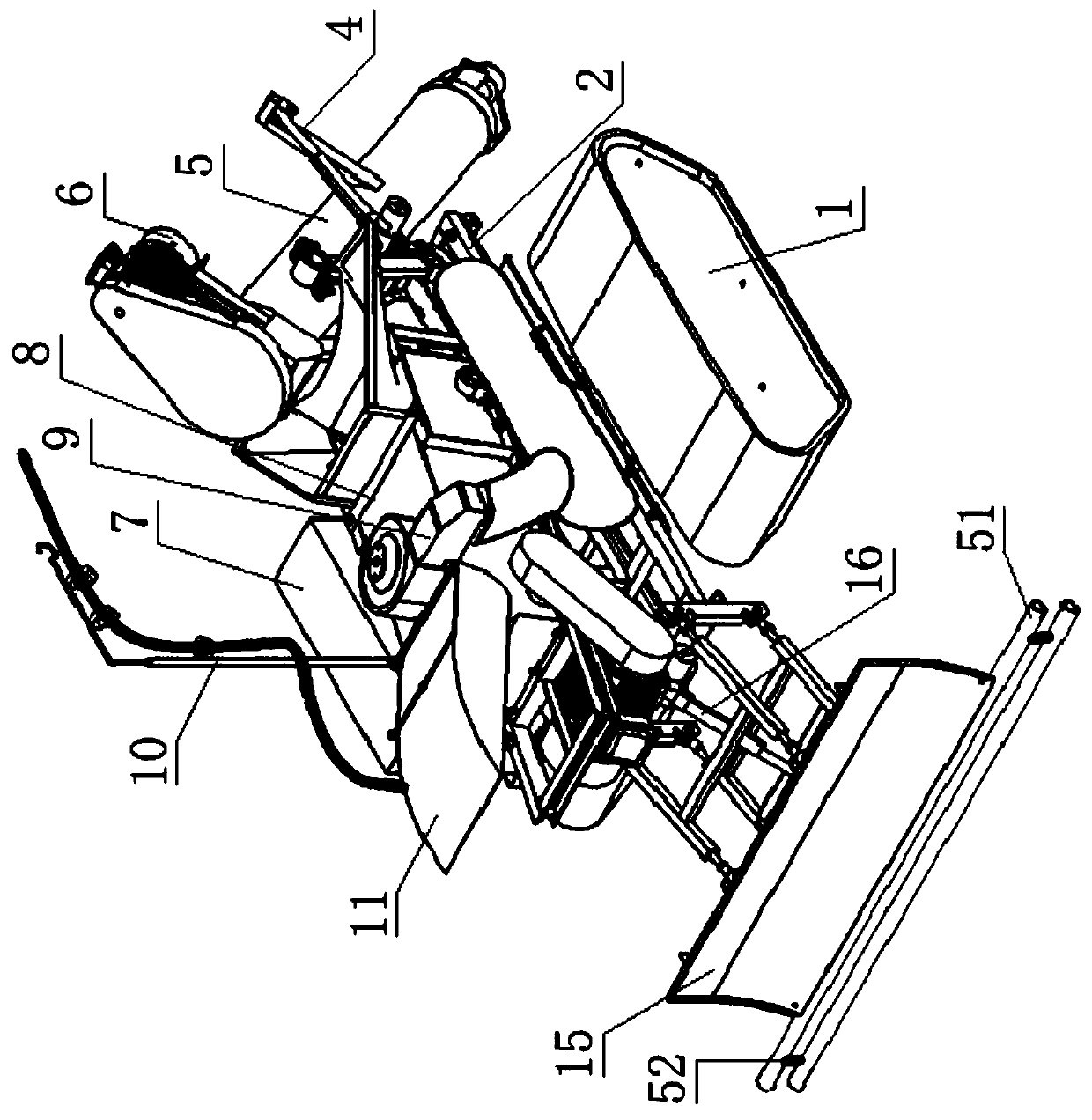

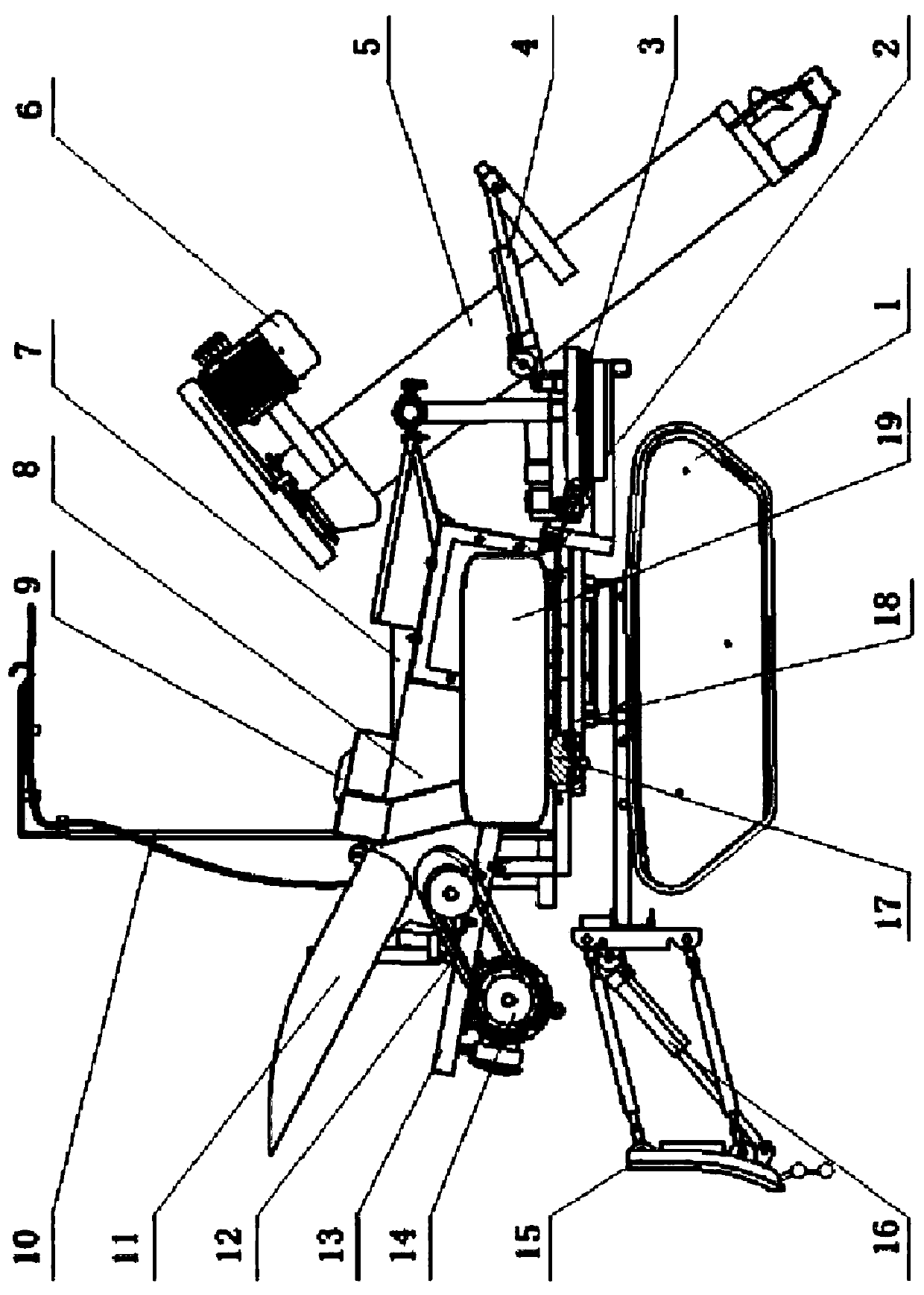

[0088] A steering-type unwinding robot that separates pumping and throwing according to the present invention includes a bottom bracket, a grain-absorbing auger device 5 , a grain-throwing conveyor belt device 8 , a grain-leveling device, a walking device 1 and a control device 7 .

[0089] Among them, there are two running devices 1, both of which are crawler-type running devices 1, and the two running devices 1 are arranged side by side on both sides of the bottom bracket at intervals, and are used to drive the bottom bracket to walk.

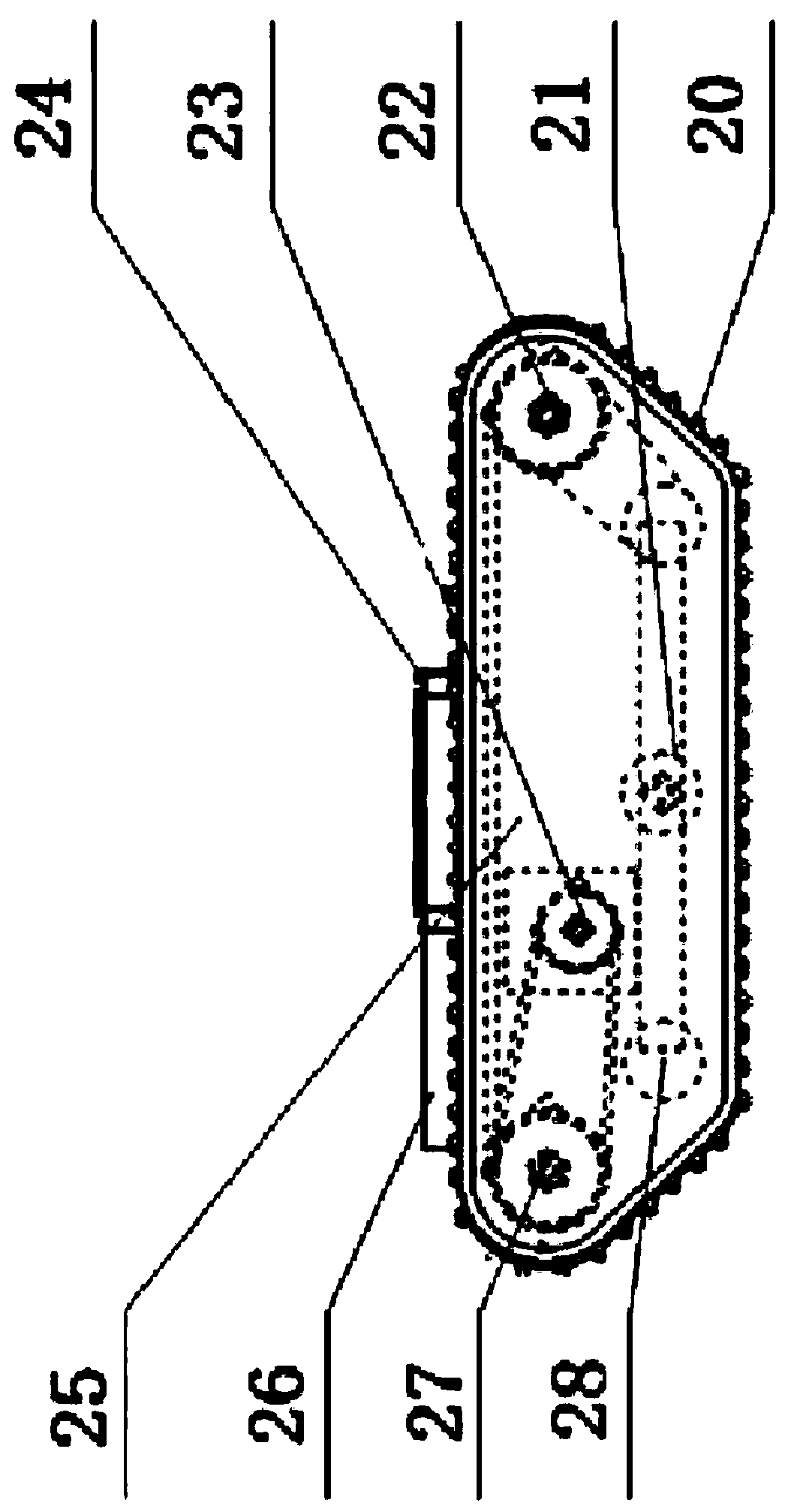

[0090]In this embodiment, the traveling device 1 is mainly composed of crawler belts 20 , supporting wheels 21 , guide wheels 22 , crawler belt drive motors 23 , bottom frames 24 , driving wheels 27 and supporting wheels 28 . The supporting wheel 21, the guiding wheel 22, the driving wheel 27 and the supporting wheel 28 are all rotatably assembled on the bottom frame 24, and the track drive is connected between the supporting wheel 21, the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com