Silicon steel sheet painting equipment for transformer

A silicon steel sheet and transformer technology, applied in the direction of inductance/transformer/magnet manufacturing, coating, surface coating liquid device, etc., can solve the problems of high labor cost and low degree of automation, achieve high degree of automation and reduce labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

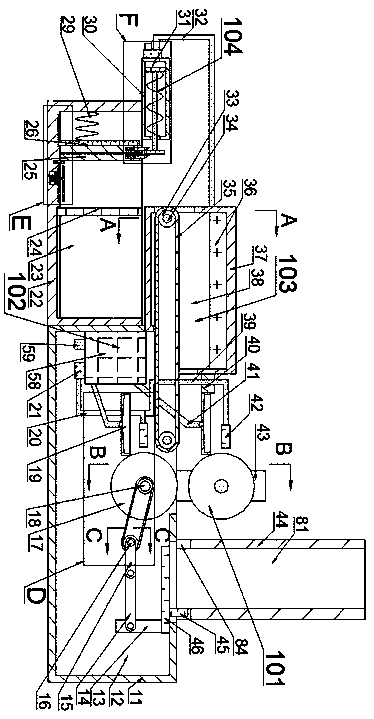

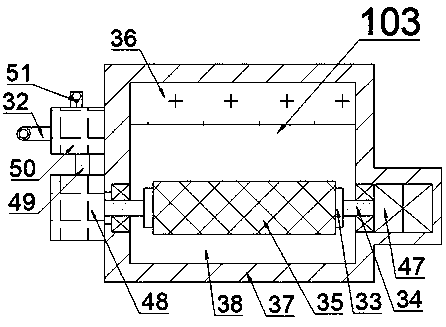

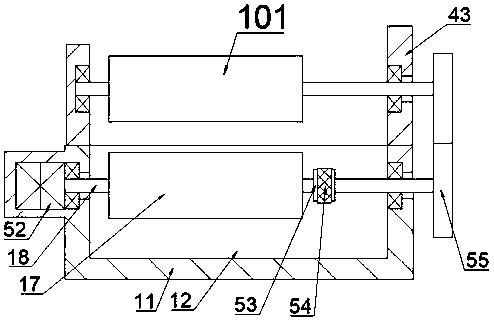

[0018] Combine below Figure 1 to Figure 7 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0019] The present invention relates to a silicon steel sheet painting equipment for transformers, which is mainly used for painting silicon steel sheets. The present invention will be further described below in conjunction with the accompanying drawings of the present invention:

[0020] A silicon steel sheet painting equipment for transformers according to the present invention comprises a chassis 11, a power chamber 12 with an opening facing upwards is provided in the chassis 11, a painting device 101 is arranged in the power chamber 12, and a painting device 101 is provided in the power chamber 12. The paint device 101 includes two symmetrical fixed plates 43 fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com