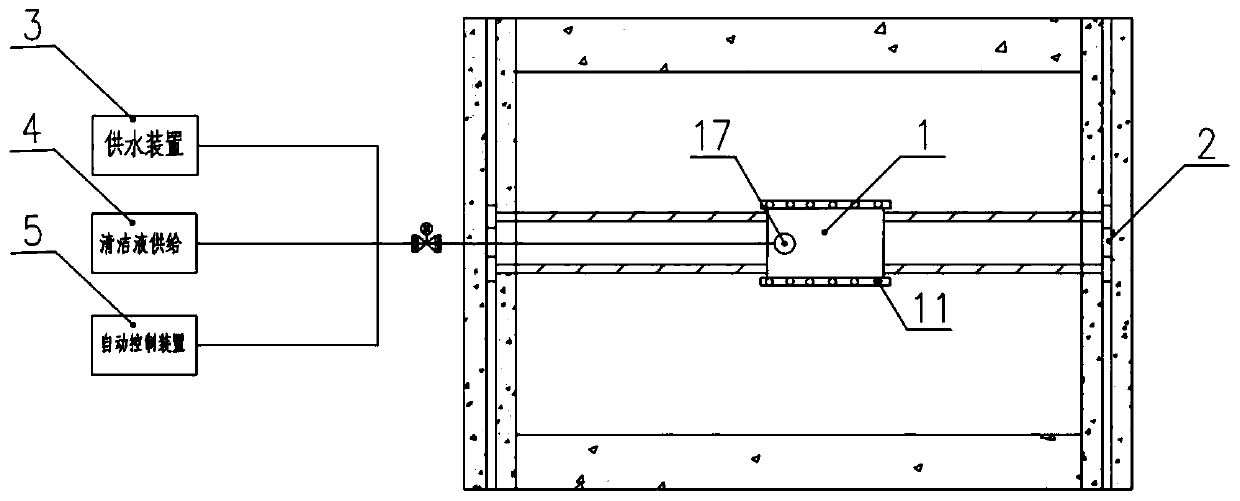

Glass cleaning device for control room of waste incineration power plant

A glass cleaning and waste incineration technology, applied in applications, cleaning equipment, household appliances, etc., can solve the problems of short service life, low reliability, affecting the observation and operation of operators, and achieve the effect of long service life and simplified moving mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

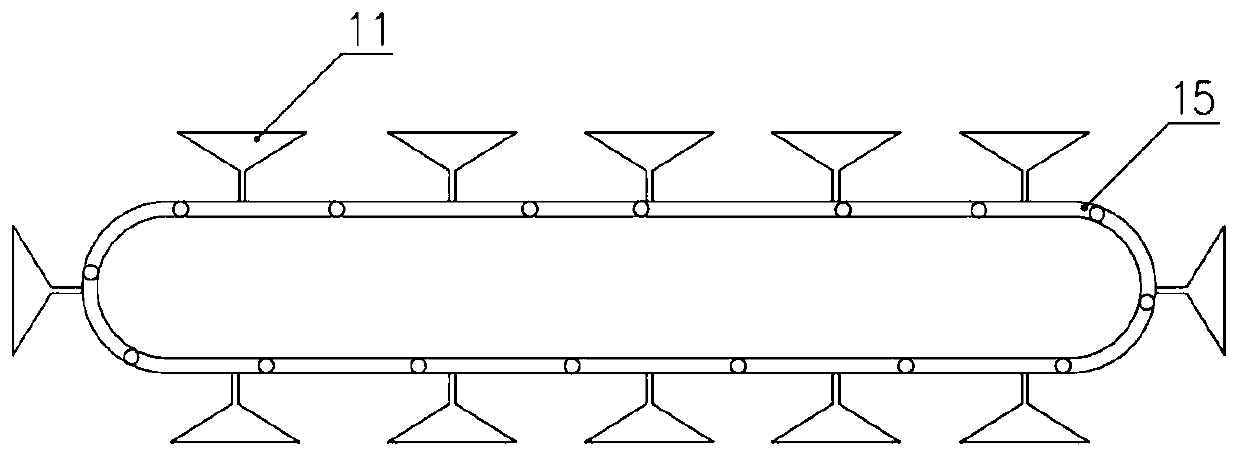

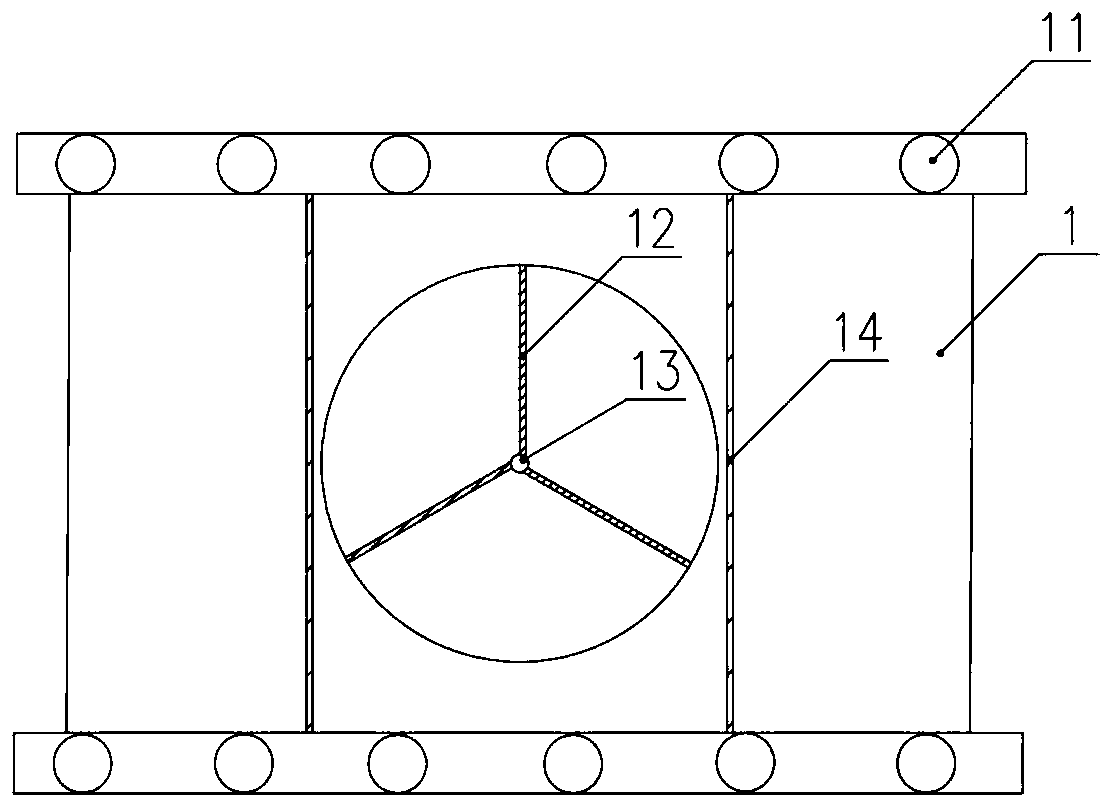

[0023] For details on cleaning component 1 above, see figure 1 and image 3 , the cleaning assembly 1 includes a cleaning plate driven by the second driving assembly, a rotating cleaning piece 12 mounted on the cleaning plate, and a spray head 13 for spraying cleaning liquid or water, and the spray head 13 is installed on the cleaning plate. On the rotary cleaning element 12 described above. In this embodiment, the cleaning method is to use rotary cleaning. During the rotation of the rotary cleaning member 12, the stains on the glass are cleaned. The nozzle 13 can spray cleaning liquid on the glass before cleaning, so as to facilitate cleaning. After cleaning, spray water to rinse off the stains. Installing the spray head 13 on the rotating cleaning element 12 can most directly spray the liquid to the area to be cleaned. Preferably, a sponge is placed at the bottom of the cleaning assembly 1, specifically, a sponge is placed at the bottom of the cleaning plate, and a cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com