Self-traction type wire coating robot wire feeding and hanging method and corresponding robot

A robot and self-tracting technology, which is applied in the direction of coating, manipulator, and device for coating liquid on the surface, etc., which can solve the problems of manual climbing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

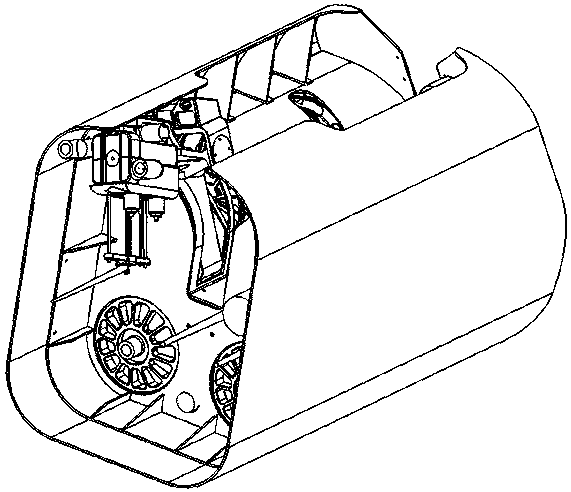

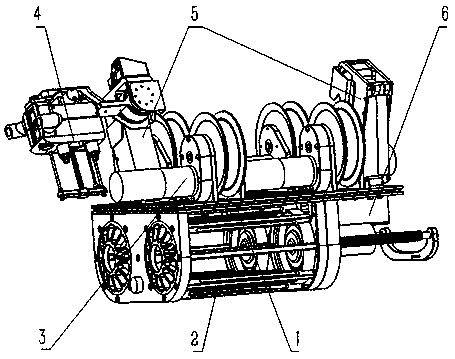

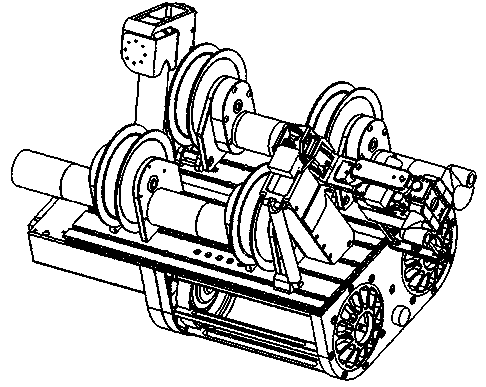

[0040] Such as Figure 1-8 Shown is a self-drawing type wire coating robot on-line hanging method, which is provided on the coating robot with a coating module 4 and a walking module that can automatically take the top of the robot as the axis and rotate toward the extension direction of the non-overhead bare wire 5. Add the reeling traction module 3 on the top of the robot. The power supply and control module 6 is at the end of the robot. Rotate the robot sideways, and then use unmanned equipment such as drones and crawling robots or directly hang the traction belt on the overhead bare wire through a long insulating rod, and tighten the traction belt through the winding traction module 3 to hang the robot on the Under the overhead bare wire, finally control the coating module 4 and the walking module 5 to rotate back to the top of the robot, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com