Overhauling tool of Hall-type reversing switch instrument

A technology for maintenance tools and switches, which is applied in the field of maintenance tools for hall-type reverse switch instruments, can solve the problems of occupying the main line of overhaul and the unit's return status, and achieve the effects of saving maintenance time, improving work efficiency, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

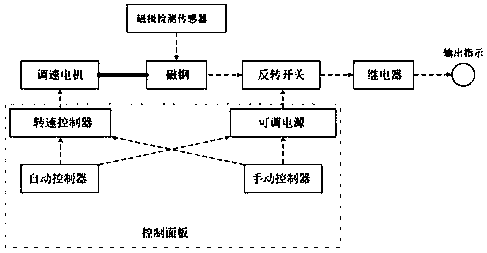

[0029] A maintenance tool for a Hall-type reversing switch instrument, which is designed in an integrated manner and mainly includes the following components: magnetic pole detection sensor device, control panel, speed-regulating motor, magnet, reversing switch, relay and output instruct.

[0030] The control panel includes speed controller, automatic controller, adjustable power supply and manual controller.

[0031] In the control panel, the automatic controller can control the speed regulating motor by controlling the speed controller, and control the reverse switch by controlling the adjustable power supply;

[0032] The manual controller can control the speed regulating motor by controlling the speed controller, and control the reversing switch by controlling the adjustable power supply.

[0033] The speed-regulating motor can control the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com