Oil well paraffin remover and inhibitor adding pipe string and method

A technology for removing and preventing wax from oil wells, which is applied to cleaning appliances, earth-moving drilling, wellbore/well components, etc., can solve the problems of waste of medicines, high labor intensity, and difficulty in controlling the concentration of medicines, so as to avoid waste. , Control the effect of dosing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

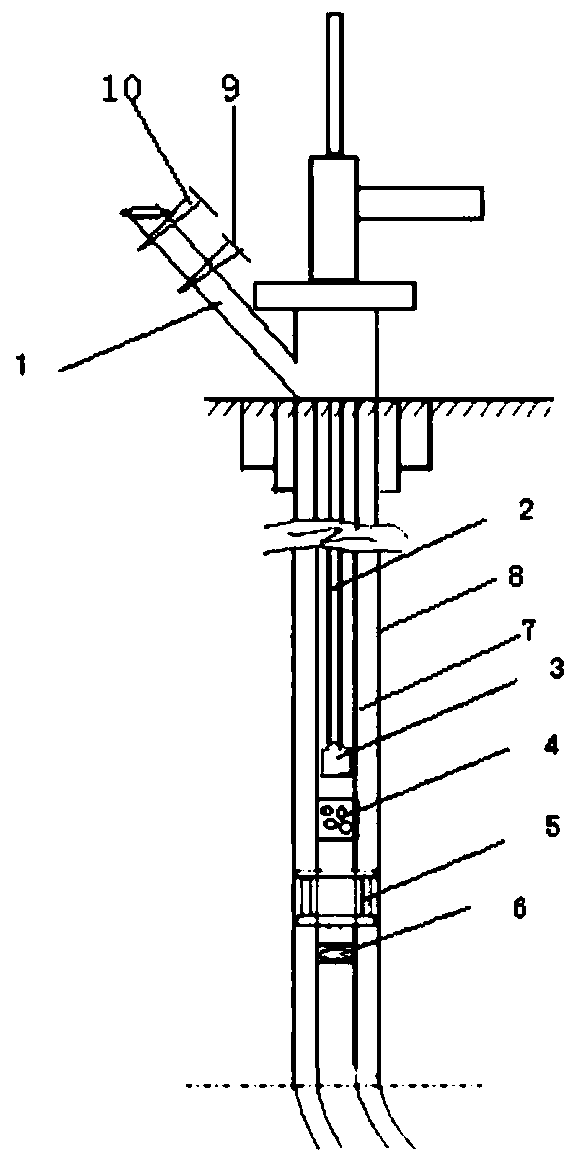

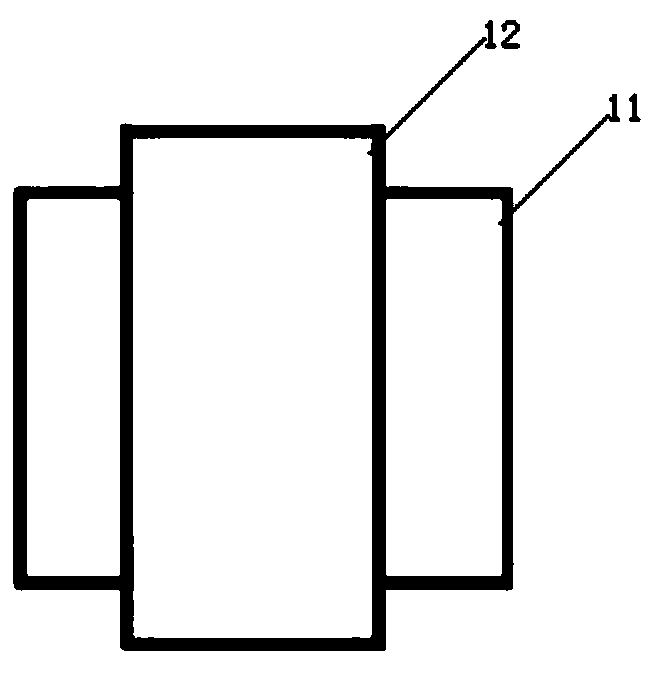

[0031] according to figure 1 The shown dosing string of wax-removing and anti-waxing agent for oil wells includes at least oil pipe 7 and casing 8, and also includes drug dosing pup 1, sucker rod 2, oil well pump 3, screen 4, receiving device 5 and box plugging 6; the dosing nipple 1 is connected to the outer wall of the casing 8 outside the wellhead, and a gate valve is arranged on the dosing nipple 1; the sucker rod 2 is connected in the tubing 7; the pumping The oil pump 3 is connected to the lower end of the sucker rod 2; the screen pipe 4 and the female plug 6 are connected to the inner wall of the oil pipe 7 from top to bottom in sequence, and the screen pipe 4 is located below the oil well pump 3; the receiving device 5 is connected to the screen pipe 4 On the outer wall of the oil pipe 7 between the plug and the female plug 6.

[0032] In actual use, the dosing nipple 1 is installed on the wellhead outer casing 8; the dosing nipple 1 is installed with a gate valve for...

Embodiment 2

[0036] according to figure 1 The shown dosing string of paraffin-removing and anti-paraffin agent for oil wells is different from the first embodiment in that the dosing pup 1 is obliquely connected to the casing 8 .

[0037] Preferably, the included angle between the drug-feeding nipple 1 and the upward direction of the axis of the wellhead casing 8 is 40°-50°.

[0038] Preferably, the angle between the drug-feeding nipple 1 and the upward direction of the axis of the wellhead casing 8 is 45° and the length is 80 cm.

[0039] In actual use, the technical solution of obliquely connecting the dosing nipple 1 and the casing 8 enables the added solid paraffin remover to fall smoothly into the receiving device 5 by gravity.

Embodiment 3

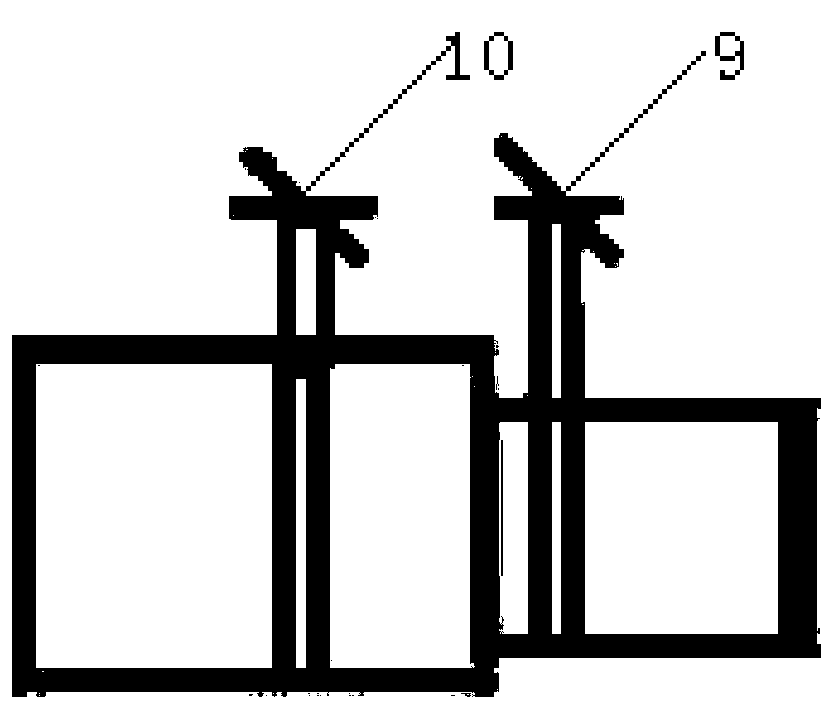

[0041] according to figure 1 and figure 2 The dosing string of an oil well wax remover and anti-wax agent shown is different from the first embodiment in that: the dosing nipple 1 is formed by connecting up and down two cylinders with different diameters, and each cylinder has a A gate valve is respectively installed, the first gate valve 9 is installed on the small diameter cylinder, and the second gate valve 10 is installed on the large diameter cylinder; one end of the small diameter cylinder is connected with the wellhead casing 8 .

[0042] Preferably, the dimensions of the two cylinders with different diameters are respectively: the cylinder with a diameter of 25mm has a length of 50cm, and the cylinder with a diameter of 62mm has a length of 30cm.

[0043] In actual use, when there is no casing gas in the oil well to add the solid paraffin remover, open the first gate valve 9 and the second gate valve 10 at the same time, and then directly add the solid paraffin remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com