A kind of electroplated silver carbon fiber electrode and preparation method thereof

A carbon fiber electrode and silver electroplating technology, applied in the field of materials, can solve the problems of complex equipment, difficult to process carbon fiber continuously and stably for a long time, and achieve the effects of good potential range performance, low cost and good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The purity of raw materials used in the preparation method of the present invention are respectively AgNO 3 (>99.0%) (commercially available), NaNO 3 (>99.0%) (commercially available), carbon fiber (commercially available). According to the design formula of the electroplating solution, the required metering of raw materials is calculated according to the stoichiometric ratio.

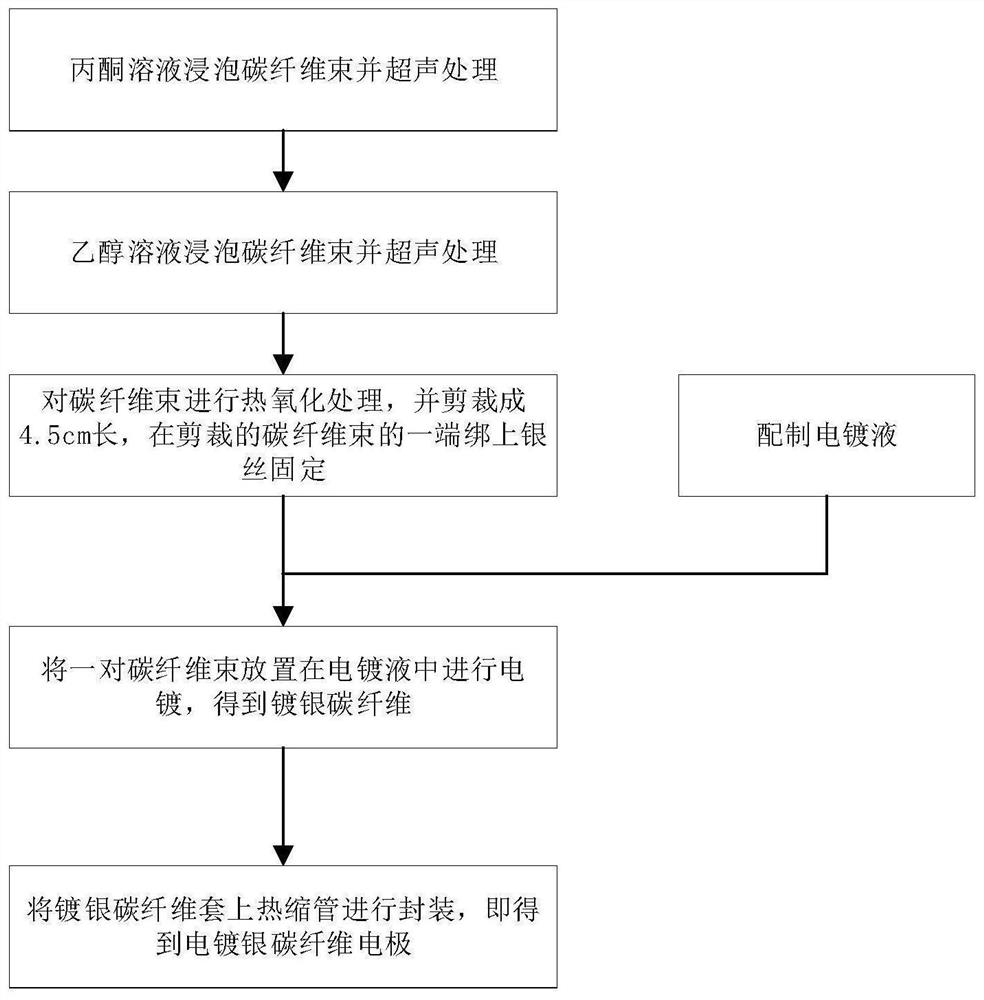

[0021] refer to figure 1 , the preparation process of embodiment 1 is:

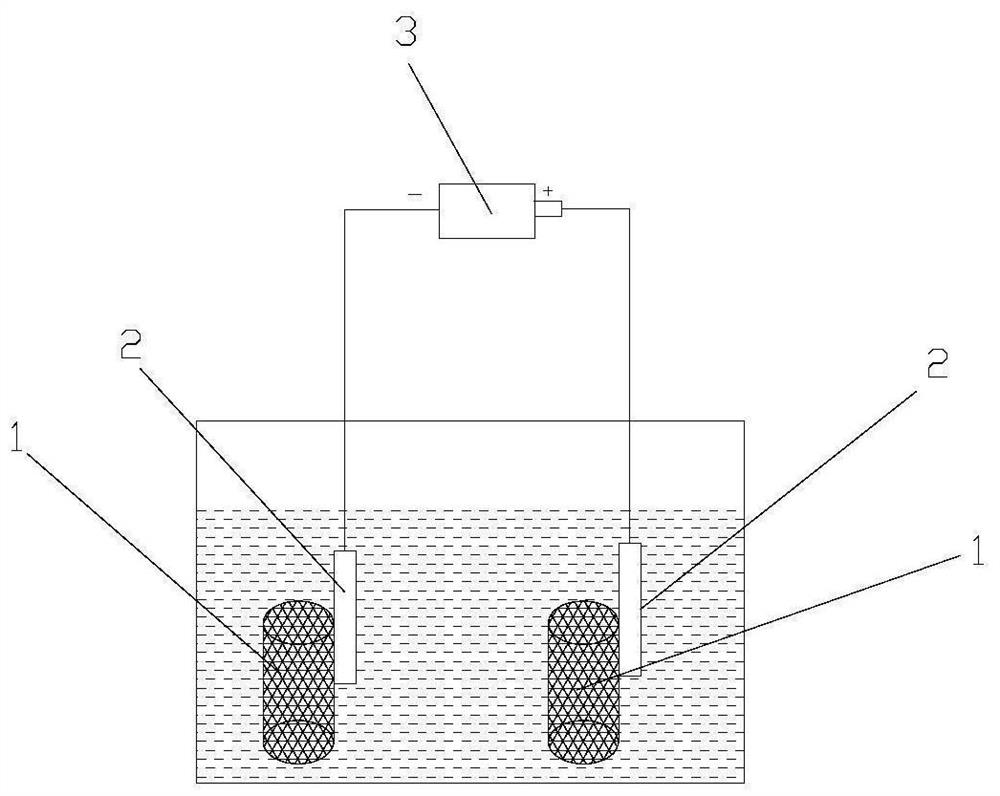

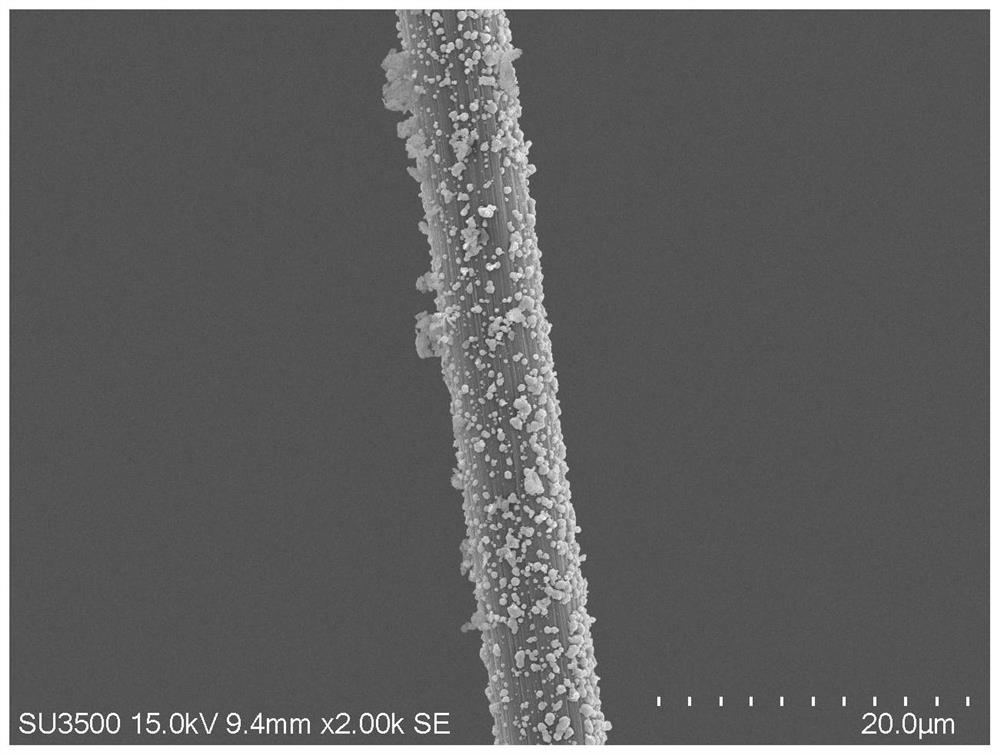

[0022] First weigh 2g of carbon fiber bundles and soak them in acetone solution for 24 hours to remove surface sizing agents and other impurities, then ultrasonically treat the carbon fiber bundles soaked in acetone solution for 30 minutes, and wash them with deionized water until neutral; then soak the carbon fiber bundles in ethanol solution And ultrasonic treatment for 30min, washed with deionized water until neutral, and then placed in a 60°C oven for 2h. Place the dried carbon fiber bundles in a muffle furnace for ...

Embodiment 2

[0027] The difference between Embodiment 2 and Embodiment 1 is only that the output voltage of the constant voltage power supply is 3V; the rest are basically the same as Embodiment 1.

Embodiment 3

[0029] The difference between embodiment 3 and embodiment 1 is only that the output voltage of the constant voltage power supply is 4V; the rest are basically the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com