Multi-liquid-chamber annular hydraulic torsional vibration damper

A technology of torsional vibration damper and liquid chamber, which is applied in the direction of shock absorber, shock absorber-spring combination, shock absorber, etc., can solve the problems of insufficient vibration damping performance, complex structure, unsatisfactory and other problems, and achieve the overall cost Low, eliminates dynamic hardening, dampening effect of torsional vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be described in detail below in conjunction with the drawings:

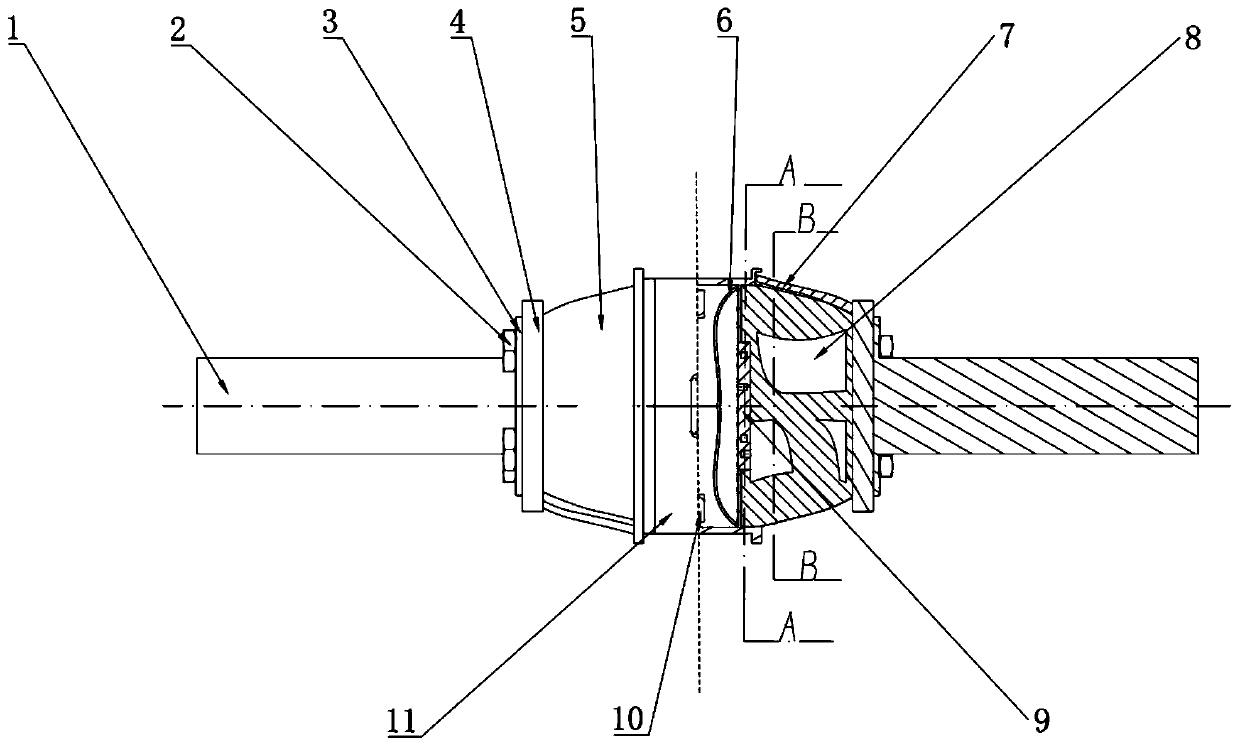

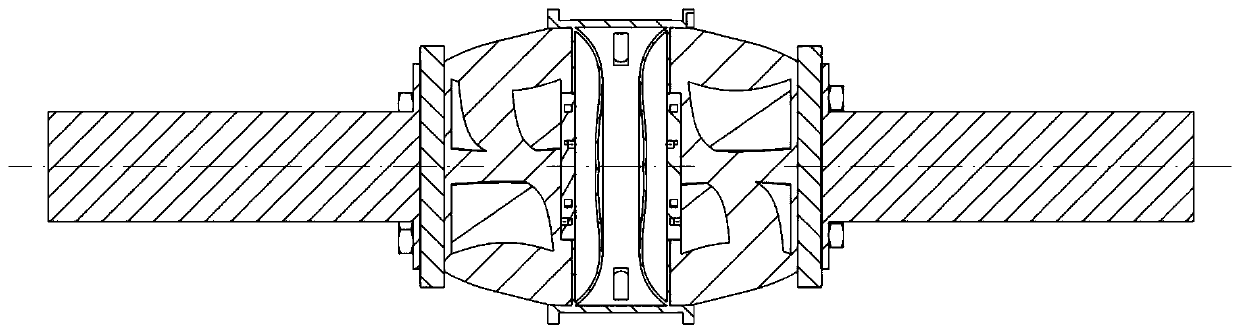

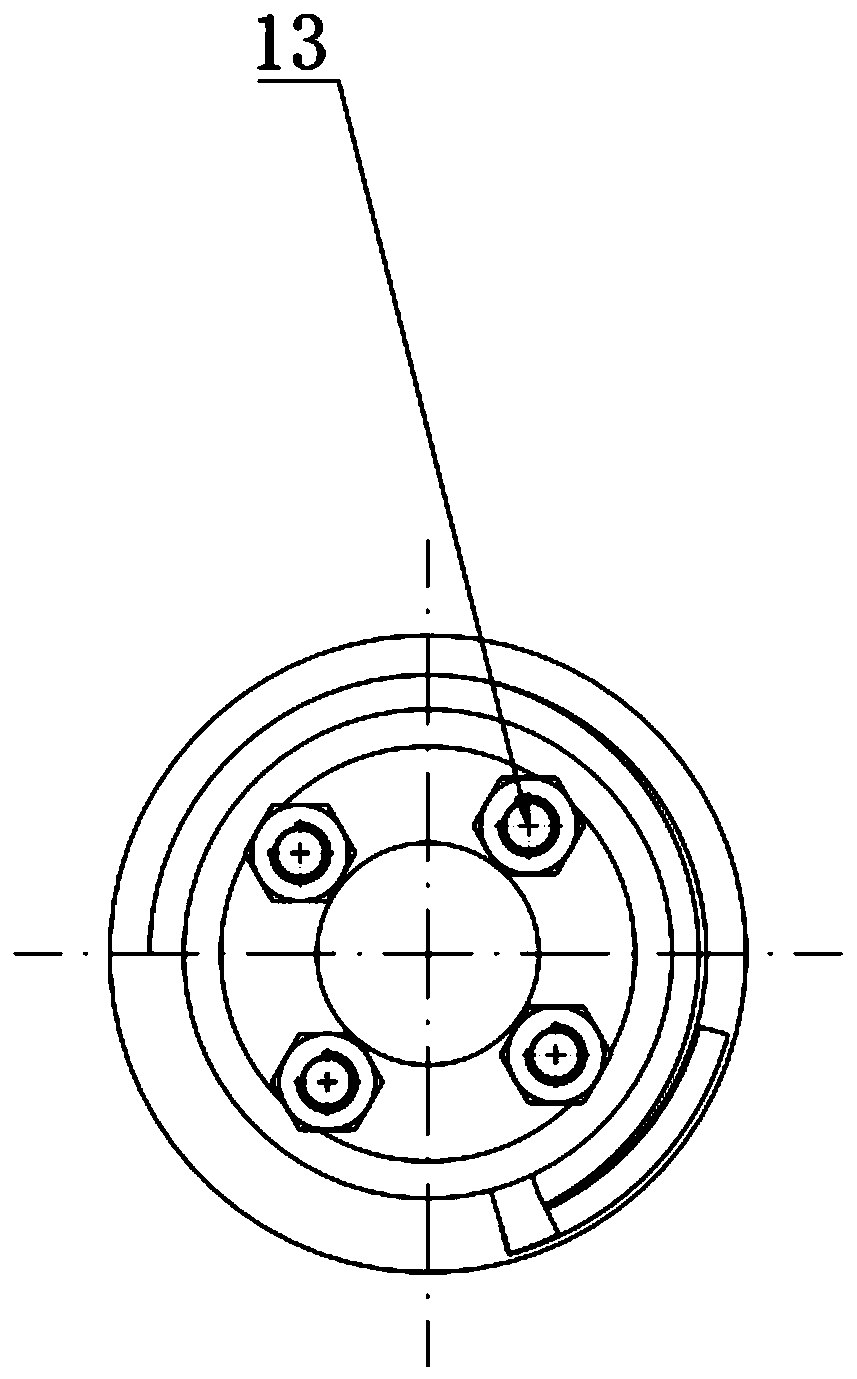

[0036] Such as Figure 1 to Figure 6 As shown, a multi-liquid annular hydraulic torsional vibration damper includes: a rubber fixing plate 4 connected to the shaft end of the left engine crankshaft 1 through a flange 3, and a left rubber liquid connected to the rubber fixing plate 4 Chamber 5, the housing 11 connected to the other end of the rubber liquid chamber 5, the right rubber liquid chamber connected to the other end of the housing, the rubber fixing plate connected to the other end of the right rubber liquid chamber, the rubber fixing plate passes through the flange Connect with the crankshaft end of the right engine. After the rubber liquid chambers 5 on the left and right sides are connected with the housing 11, the whole structure is mirror-symmetrical with respect to the axial center surface of the housing 11. Inertial channels 9 are provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com