A shot blasting machine capable of screening steel shot

A shot blasting machine and steel shot technology, which is applied to used abrasive processing devices, metal processing equipment, manufacturing tools, etc., can solve the problem of not having the ability to screen steel shot, achieve good stability, increase effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

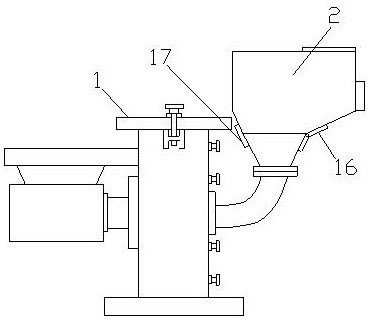

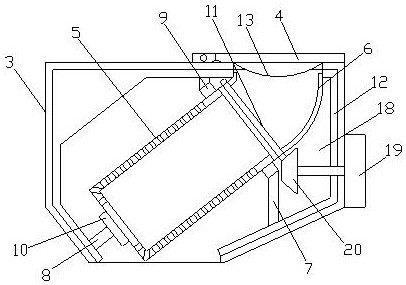

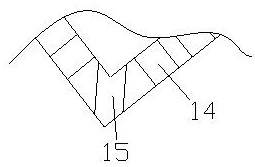

[0026] like Figure 1-4 As shown in, sieved A Shot blasting machine, shot blasting machine comprising a body 12 and the screening device, the screening device 2 includes a body 3, the discharge opening is provided with a tank 3 (not shown) and a feed port (not shown), a discharge opening at the blasting machine main body 1 is connected through the discharge opening, the upper body 2 is provided with a feed port for covering lid 4, the cover 4 is connected to the hinge body 3, the tank body 5 is provided with a sieve tube, pipe 6, a first and a second support bracket 8 7, 7 disposed on the first support a bearing 9, the bearing body 5 and the sieve tube 9 fixedly connected to the sieve drum 5 is rotatably connected through a bearing member 9 and the first support 7, the second end of the support frame 8 is provided with a turntable 10 the turntable motor 10 is fixedly connected to the sieve tube 5, the inclined screening drum 5 suspended within the tank 1, one end of the bend 6 in c...

Embodiment 2

[0029] like Figure 1-4As shown, a shot blasting machine for sieving steel pills includes a shot blasting machine body 1 and a screening device 2, the screening device 2 comprises a can body 3, and a tank 3 is provided on (Not shown) and the feed port (not shown), the hose port is in communication with the blanket machine body 1, and the tank 2 is provided with a cover for covering the feed port. 4, the cover 4 is hinged to the tank 3, and the tank is provided with a sifter 5, a bending tube 6, a first support frame 7, and a second support frame 8, and disposed on the first support frame 7. There is a bearing body 9, and the screen cartridge 5 is fixed to the bearing body 9, and the screen cartridge 5 is rotated by the bearing body 9 and the first support frame 7, and the second support frame 8 is provided with an electric turntable 10. The electric turntable 10 is fixed to the screen cartridge 5, and the screen cartridge 5 is inclined by the electric turntable 10 and the bearing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com