A sand scraping mechanism for cast iron casting

A technology of pig iron castings and gear cylinders, which is applied in the field of pig iron casting castings, can solve problems such as time-consuming and labor-intensive problems, and achieve the effects of improving the quality of finished products, saving casting time, and simple and labor-saving sand scraping processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

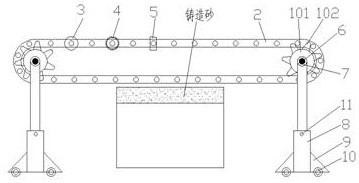

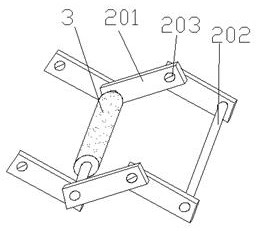

[0022] refer to Figure 1-2 , a sand scraping mechanism for pig iron castings, including a chain plate 2 erected by two gear cylinders 1, the gear cylinder 1 is specifically composed of a horizontally placed cylinder 101 and rings distributed outside the cylinder 101 The gear bar 102 is formed, the chain plate 2 is composed of link units, and each link unit includes four straight plates 201 and connecting shafts 202, one end of the connecting shaft 202 passes through two straight plates 201 in turn, and shoulders are set on both sides of the two straight plates 201 part, so that two straight plates 201 are positioned at one end of the connecting shaft 202, and the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com