Cable bushing

A technology for cables and some components, applied in the field of cable lead-throughs, can solve the problems of high sealing and non-allowance, and achieve the effect of high sealing and simple sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

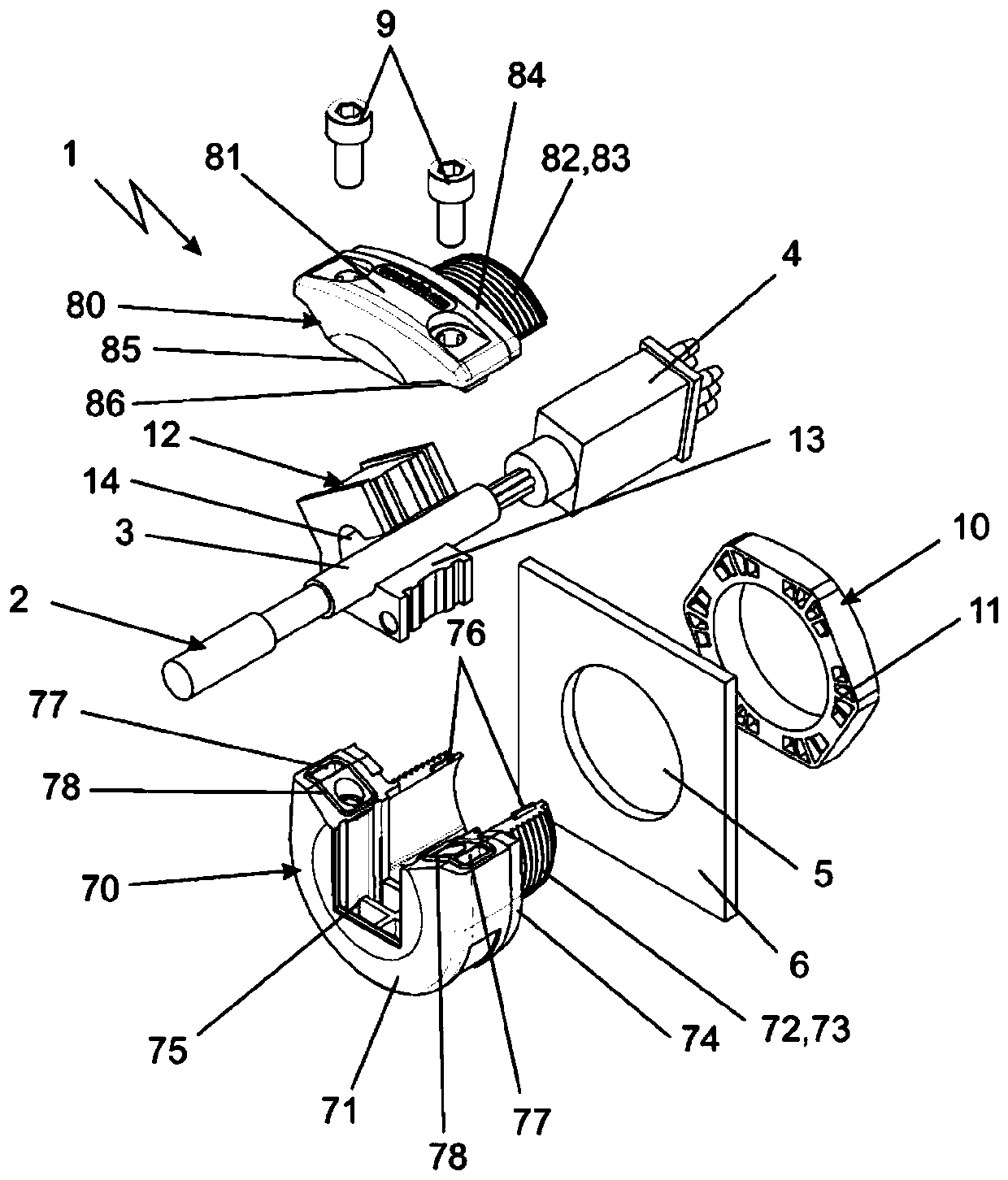

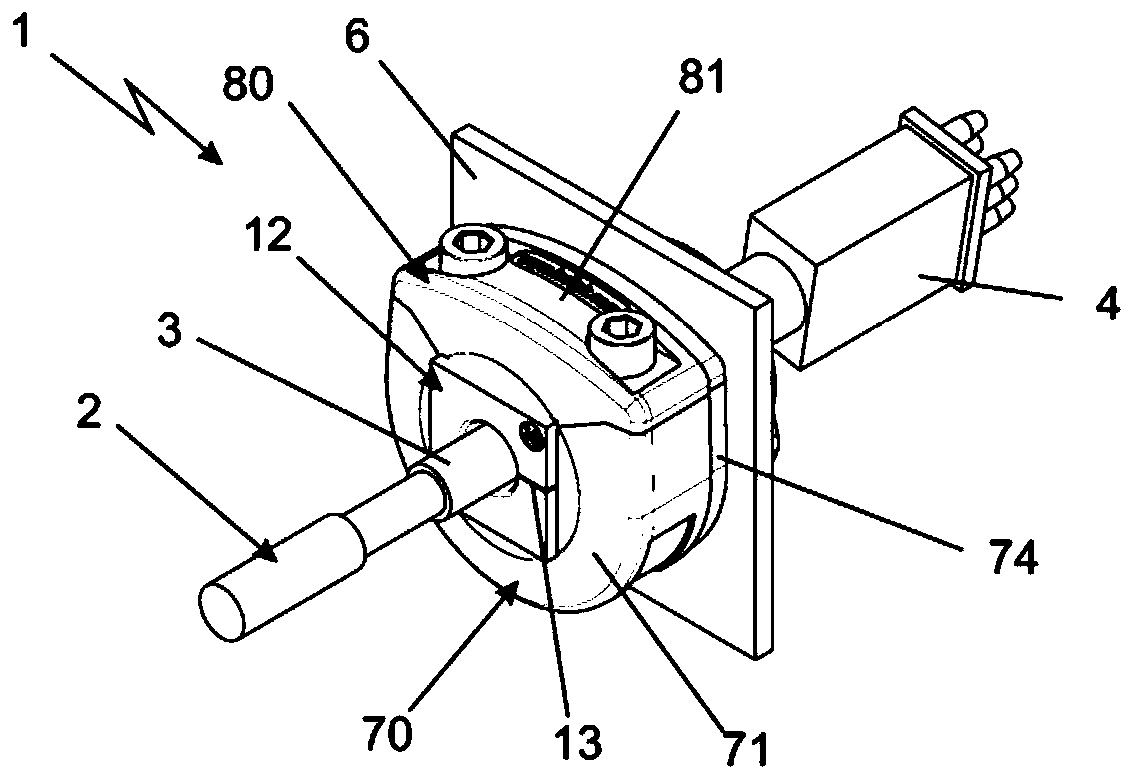

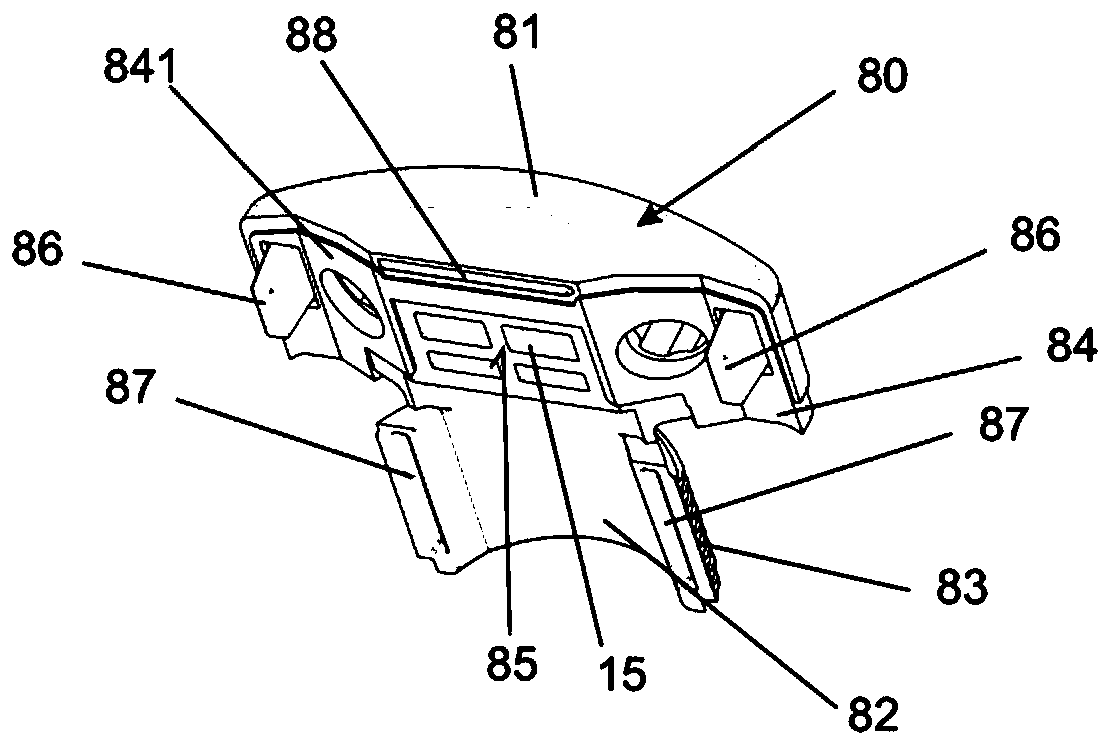

[0025] exist figure 1 A three-dimensional exploded representation of the cable lead-through 1 can be seen in the illustration of . The cable lead-through 1 serves to accommodate a prefabricated cable 2 , which is shown here, for example, as a cable section 3 and a plug 4 mounted thereon. Such a prefabricated cable 2 should pass through a recess 5 in the wall marked with reference 6 , only a section of which is shown here. The wall indicated at 6 can in particular be a wall of a switchgear cabinet which is not shown in its entirety. The cable lead-through 1 comprises two sub-elements 70 , 80 which are screwed together by means of two screws 9 . Each partial element 70 , 80 has a receiving section 71 , 81 facing the viewer and a threaded section 72 , 82 with an external thread 73 , 83 arranged facing away from the viewer. The threaded section 72 passes through the recess 5 of the wall 6 and is screwed through the nut 10 . Thus, the wall 6 is held clampingly between the nut 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com