Circuit board developing solution recycling system

A technology of recycling and developing solution, which is applied in photography, optics, instruments, etc., can solve the problems of high pollution of developing solution, mesh clogging and filtration cost, etc., to prevent the sedimentation and accumulation of rubber slag, reduce filtration cost and reduce pollution degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

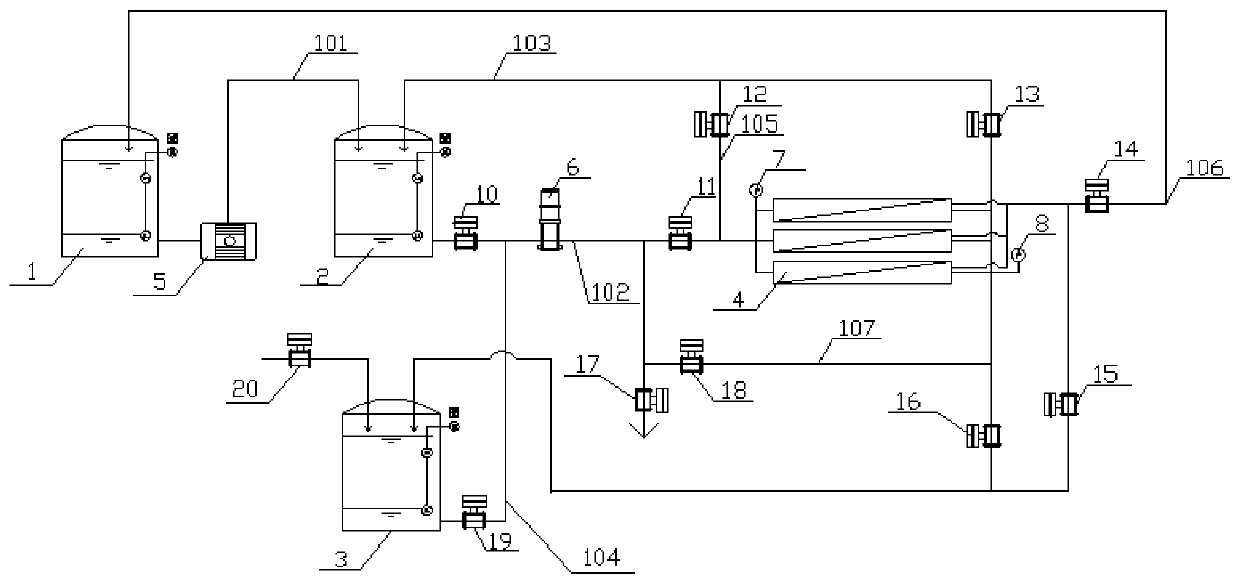

[0017] A circuit board developing solution circulation recovery system, comprising a developing solution tank 1, the discharge port of the developing solution tank 1 is connected to the feed port of the concentrated water tank 2 through a first pipeline 101, and a stock solution lifting pump 5 is installed on the first pipeline 101, The discharge port of the concentrated water tank 2 is connected to the feed port of the membrane filtration device 4 through the second pipeline 102, and the water inlet valve 10, the filter high-pressure pump 6 and the forward water inlet valve 11 are successively installed on the second pipeline 102, and the membrane filter The first discharge port of the device 4 is connected to the feed port of the developer tank 1 through the sixth pipeline 106, the sixth pipeline 106 is equipped with a water production valve 14, and the second discharge port of the membrane filtration device 4 passes through the third The pipeline 103 is connected to the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com