Optimized sweep frequency excitation method for vibrating wire collector

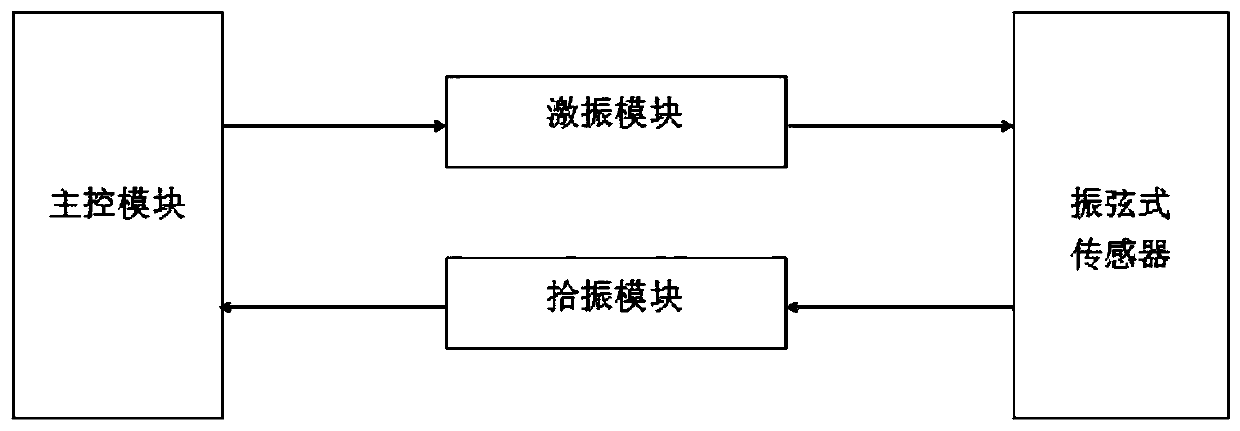

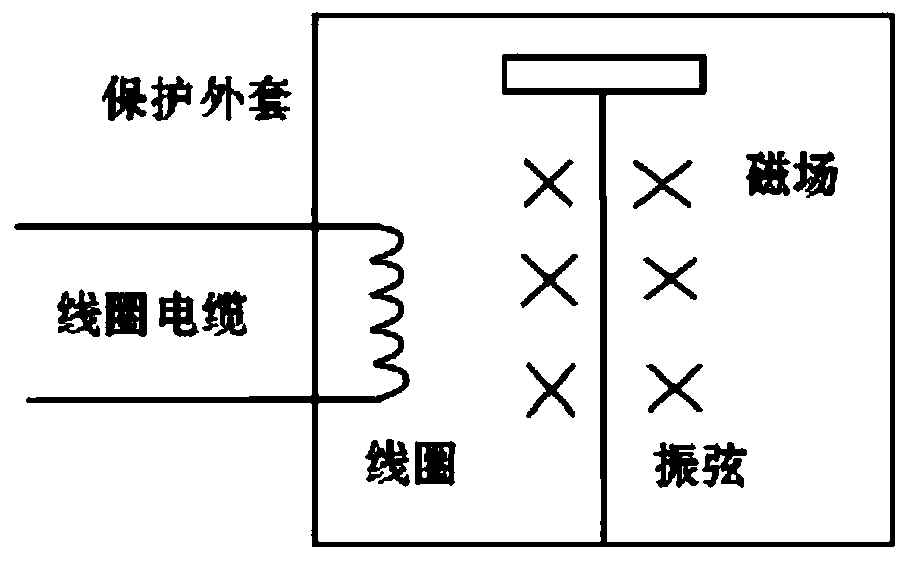

A collection instrument and frequency sweeping technology, which is applied in the field of optimized vibrating wire collection instrument sweep frequency excitation, can solve the problems of frequency measurement quantization error, frequency measurement method quantization error, sensor signal can not be measured, etc., to shorten time and prolong work the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

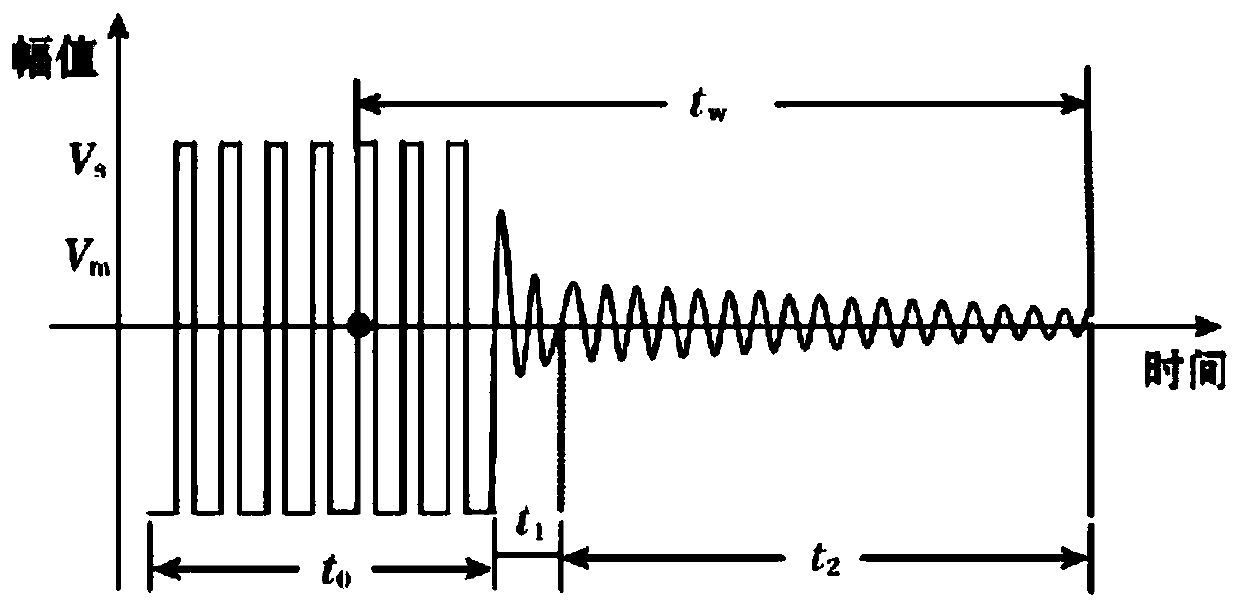

[0044] Example 1. An optimized frequency sweep excitation method for a vibrating wire collector, the method comprising:

[0045] Step 1: In the pre-sweep frequency excitation stage, first set the pre-sweep frequency excitation range and the incremental step size of the pulse sequence. The frequency sweep range in the pre-sweep frequency excitation stage is the working frequency range of the full frequency band of the vibrating wire [f min , f max ], where f min = 400Hz, f max =6000Hz, the pre-sweep pulse sequence incremental step is set to f p =20Hz, and then send the pre-sweep frequency excitation pulse sequence to pick up the vibration and measure the frequency. According to the frequency measurement data, check whether the vibrating wire is reliably excited. If so, obtain the resonance frequency of the sensor and enter the second step. If not, do error processing;

[0046] The frequency sweep excitation parameters mentioned above, the sweep frequency excitation duration...

Embodiment 2

[0058] Example 2. An optimized vibrating wire acquisition instrument sweep frequency excitation method, the method is the same as the method in embodiment 1, wherein the pre-sweep frequency excitation stage adopts a 10Hz sweep pulse sequence incremental step; the complex sweep stage adopts a 0.1Hz sweep Frequency pulse increment step size.

Embodiment 3

[0059] Example 3. An optimized vibrating wire acquisition instrument sweep frequency excitation method, the method is the same as the method in embodiment 1, wherein the pre-sweep frequency excitation stage adopts a 30Hz sweep pulse sequence incremental step; the complex sweep stage adopts a 0.9Hz sweep Frequency pulse increment step size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com