Stepped anti-puncture fabric with lap joint seam and preparation method thereof

A ladder-like fabric technology, applied in protective equipment, offensive equipment, personnel protection equipment, etc., can solve problems such as the impossibility of sewing stab-resistant fabrics and the risk of gaps in stab-resistant sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

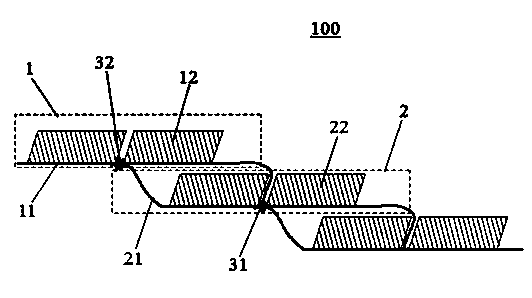

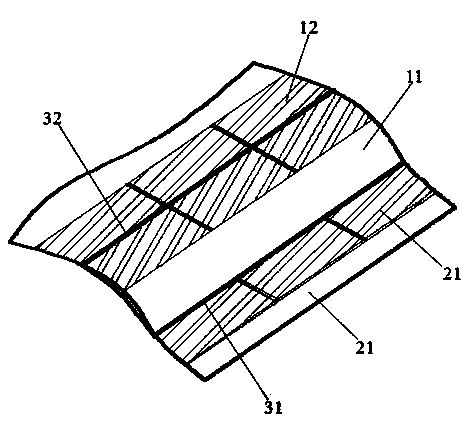

[0035] Please refer to Figure 1-Figure 5 , the present embodiment is a stepped stab-resistant fabric 100 with overlapping gaps, which includes a number of alternately overlapping first fabric units 1 and second fabric units 2, the first fabric unit 1 includes a first base fabric 11, Several rows of the first stab-proof sheet group 12 laid on the first base cloth 11, the second fabric unit 2 includes the second base cloth 21, several rows of the second stab-proof sheet group 22 laid on the second base cloth 21, The tail end of the first base cloth 11 is sewn with the second base cloth 21 at the first seam line 31 from above, and the front end of the second base cloth 21 is sewn with the first base cloth 11 at the second seam line 32 from below. A stitching line 31 is positioned between two adjacent rows of first stab-proof sheet groups 12, and a second stitching line 32 is positioned between two adjacent rows of second stab-proof sheet groups 22; The anti-stab group 12 overla...

Embodiment 2

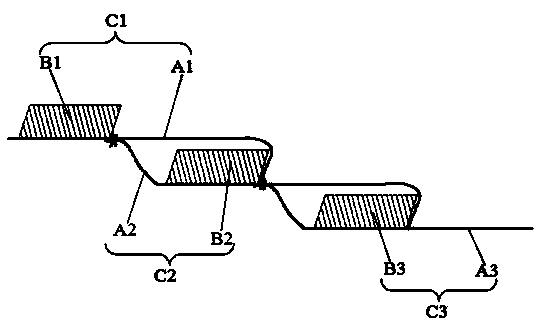

[0050] The present embodiment provides a preparation method of a stepped stab-resistant fabric with lapped gaps, which comprises the following steps:

[0051] 1) A base fabric A is provided, and two rows of anti-stab sheet groups B and D are laid on the base cloth at a set distance to obtain a fabric unit C. The anti-stab sheet group B is located in the first row of the fabric unit C. Sheet group D is located in the last row of fabric unit C;

[0052] Several rows of anti-stab sheet groups can be laid in the middle setting distance, and non-contact lap joints are set between two adjacent rows of anti-stab sheet groups;

[0053] 2) Repeat step 1) to obtain several fabric units C1, C2, ..., Cn with the same structure;

[0054] 3) Sew the front end of a fabric unit C2 together with a fabric unit C1 near the front edge of the last row of anti-stab sheet group D1 from below, then take another fabric unit C3, and sew its front end together with the fabric unit C2 from below Sew to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com