Molten salt conveying system for solar photo-thermal power station

A technology of solar energy and power stations, applied in the field of molten salt delivery system, can solve the problems of rising production cost, long delivery cycle and high price of molten salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

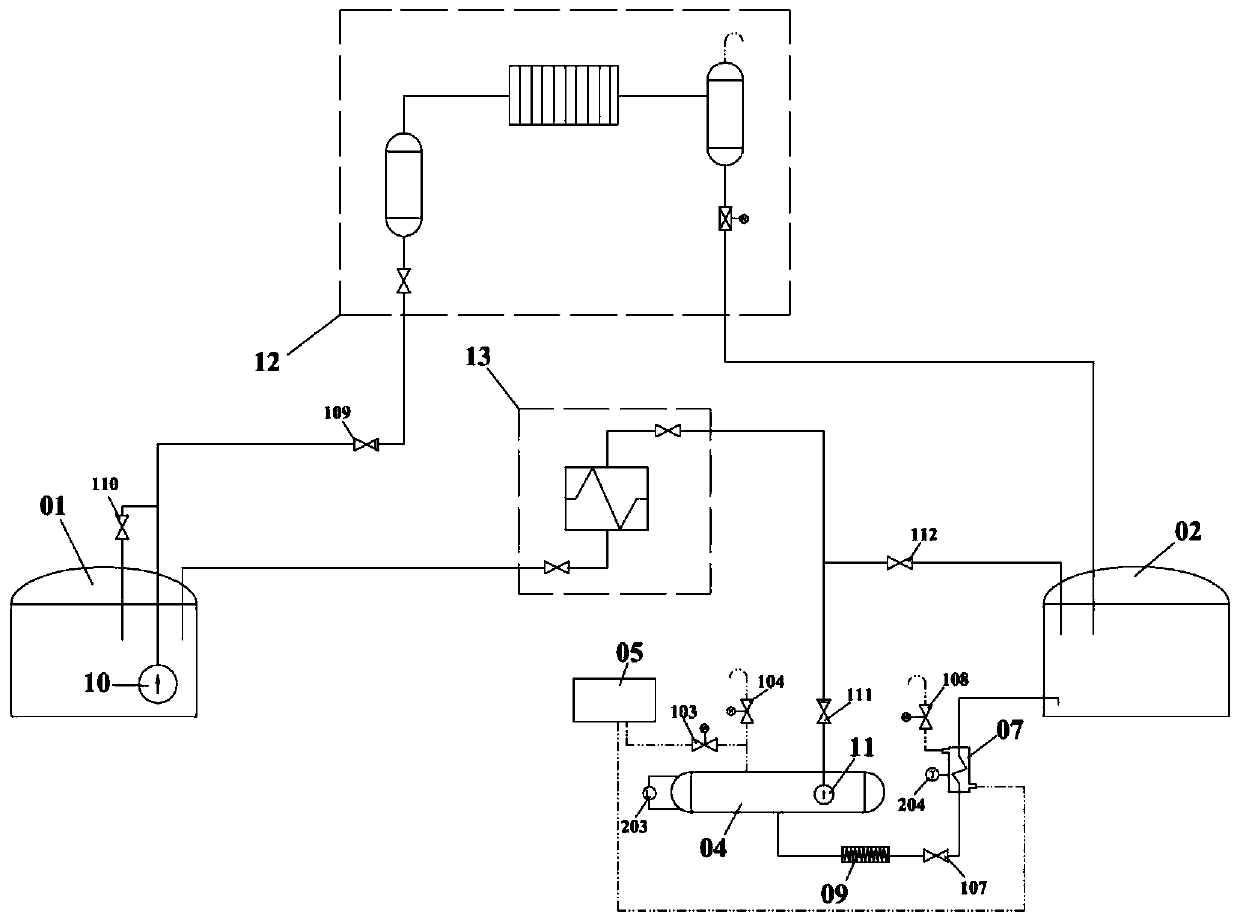

[0050] as attached figure 1 As shown, a molten salt delivery system for a solar thermal power station includes: a high-level tank system, a molten salt heat absorption subsystem 12, a molten salt heat exchange subsystem 13, and a molten salt transmission subsystem;

[0051] The high-level tank system includes: low-temperature molten salt storage tank 01, high-temperature molten salt storage tank 02;

[0052] The molten salt transmission subsystem includes a high temperature molten salt transmission subsystem.

[0053] The high-temperature molten salt transmission subsystem is set corresponding to the high-temperature molten salt storage tank 02; the high-temperature molten salt transmission subsystem includes a high-temperature molten salt low-level tank 04; the installation height of the high-temperature molten salt low-level tank 04 is lower than the The high-temperature molten salt storage tank 02; the volume of the high-temperature molten salt low-level tank 04 is smaller...

Embodiment 2

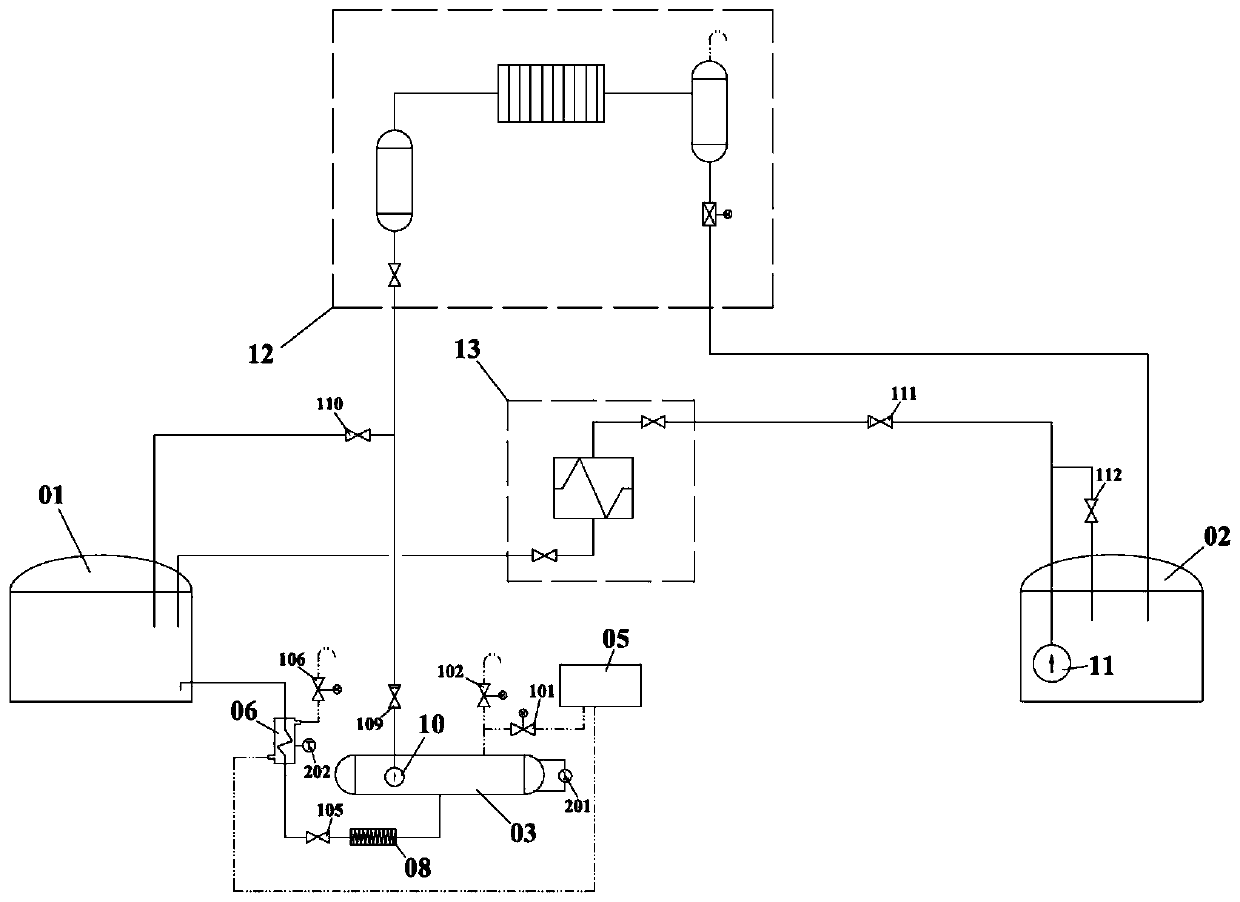

[0078] as attached figure 2 As shown, a molten salt delivery system for a solar thermal power station includes: an elevated tank system, a molten salt heat absorption subsystem 12, a molten salt heat exchange subsystem 13, and a molten salt transmission subsystem.

[0079] The high-level tank system includes: low-temperature molten salt storage tank 01, high-temperature molten salt storage tank 02;

[0080] The molten salt transmission subsystem includes a low temperature molten salt transmission subsystem.

[0081] The low-temperature molten salt transmission subsystem is set corresponding to the low-temperature molten salt storage tank 01; the low-temperature molten salt transmission subsystem includes a low-temperature molten salt low-level tank 03; the installation height of the low-temperature molten salt low-level tank 03 is lower than the The low-temperature molten salt storage tank 01; the volume of the low-temperature molten salt low-level tank 03 is smaller than th...

Embodiment 3

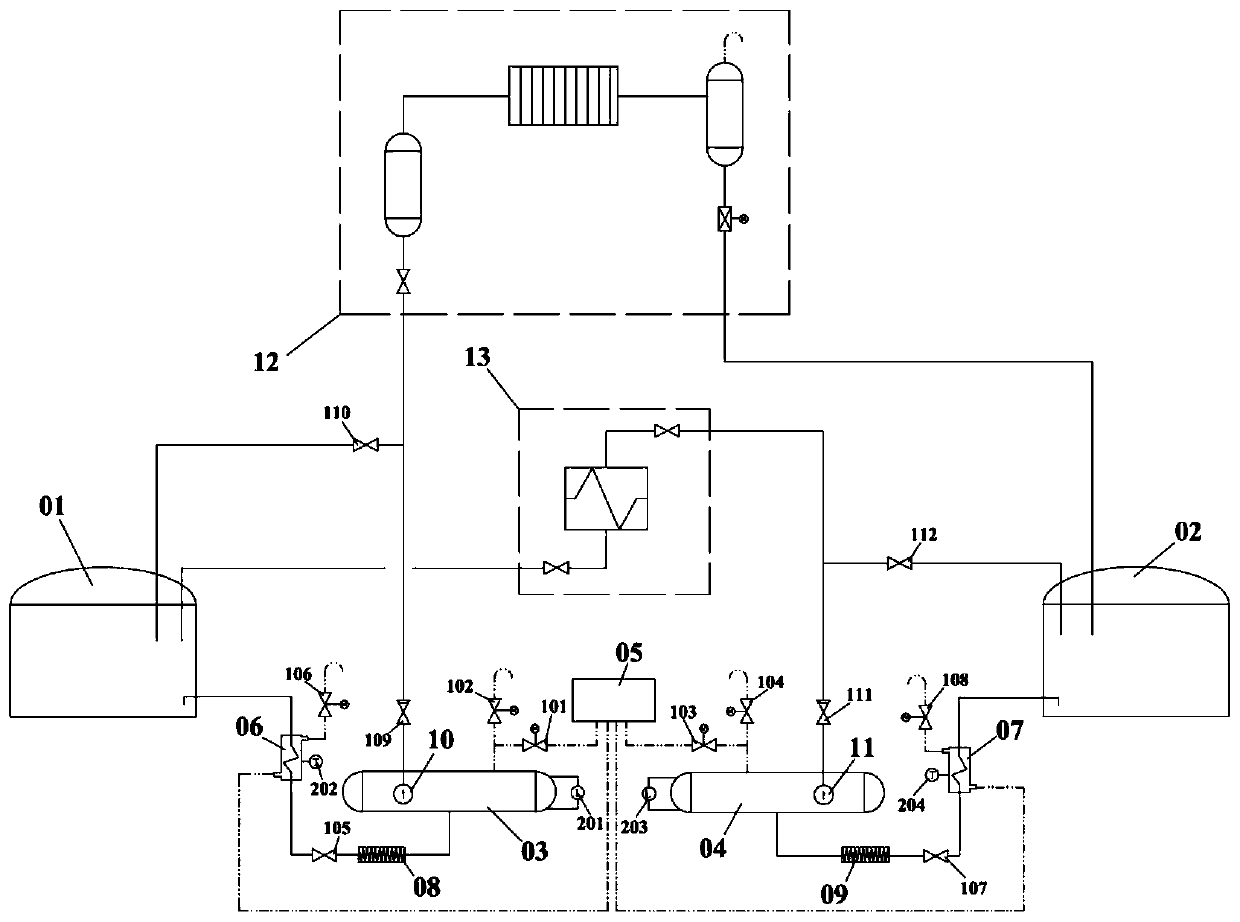

[0108] as attached image 3 As shown, a molten salt delivery system for a solar thermal power station includes: a high-level tank system, a molten salt heat absorption subsystem 12, a molten salt heat exchange subsystem 13, and a molten salt transmission subsystem;

[0109] The high-level tank system includes: low-temperature molten salt storage tank 01, high-temperature molten salt storage tank 02;

[0110] The molten salt transmission subsystem includes a high temperature molten salt transmission subsystem and a low temperature molten salt transmission subsystem.

[0111]The high-temperature molten salt transmission subsystem is set corresponding to the high-temperature molten salt storage tank 02; the high-temperature molten salt transmission subsystem includes a high-temperature molten salt low-level tank 04; the installation height of the high-temperature molten salt low-level tank 04 is lower than the The high-temperature molten salt storage tank 02; the volume of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com