Electric heating control system based on power line carrier communication and working method

A technology of power line carrier and control system, which is applied in heating system, heating mode, space heating and ventilation, etc. It can solve the problems of cost increase, wireless communication control dead angle, and low actual utilization rate, so as to reduce radiation and facilitate construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

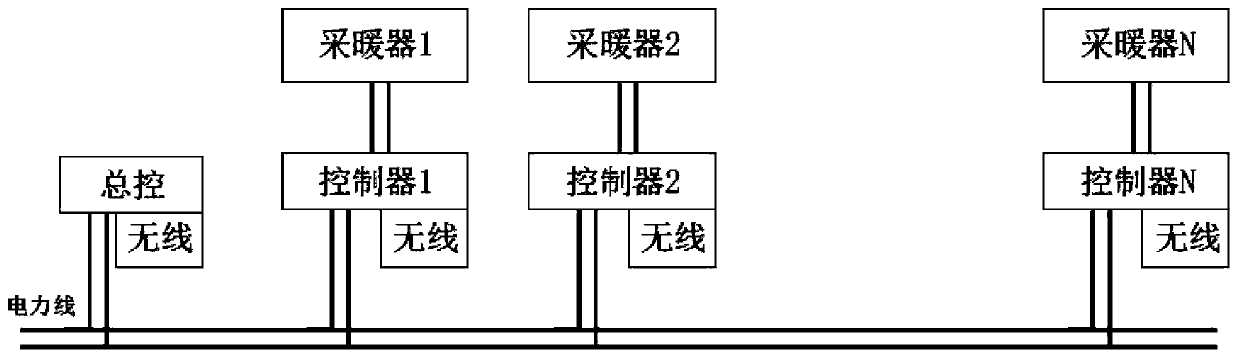

[0041] Embodiment 1 of the present application provides an electric heating control system based on power line carrier communication, including a quantifier and multiple temperature controllers connected in parallel on the power line, and is suitable for electric heating control systems of single-phase power line and multi-phase power line carrier , each thermostat is used to control the start and stop of the heating equipment connected to it, the quantifier communicates with the thermostat through the power line carrier, and calculates the most suitable target thermostat for starting and stopping through the adjustment algorithm, so that the corresponding heating Equipment starts and stops heating to achieve optimal energy allocation.

[0042] image 3is a single-phase power line carrier control diagram, such as image 3 As shown, the power line is a 220V AC bus, and the quantifier and multiple thermostats are connected in parallel on the power line. The quantifier controls ...

Embodiment 2

[0071] Embodiment 2 of the present application provides a working method of an electric heating control system based on power line carrier communication, which is applied to a system composed of a quantifier and a thermostat;

[0072] Described quantifier working method comprises:

[0073] After the quantifier is powered on, the start signal is coupled to the power line through the power line carrier module and sent to the corresponding thermostat group;

[0074] And, the quantifier collects the total current of all thermostats from the power line. If the total current of the thermostat exceeds the preset total current set in the quantifier, it will query the most suitable thermostat group to stop. According to the most suitable The stopped thermostat group gets a stop instruction, and the stop instruction is coupled to the power line through the power line carrier module;

[0075] And, the quantifier receives the adjusted power consumption instruction sent by the upper appli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com