Manipulation display panel, manufacture method thereof and induction cooker

A display panel and induction cooker technology, which is applied in the field of induction cooker, can solve the problems of touch feedback sensitivity reduction, touch operation interference, and inability to ensure surface bonding, etc., and achieve the effect of improving touch sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

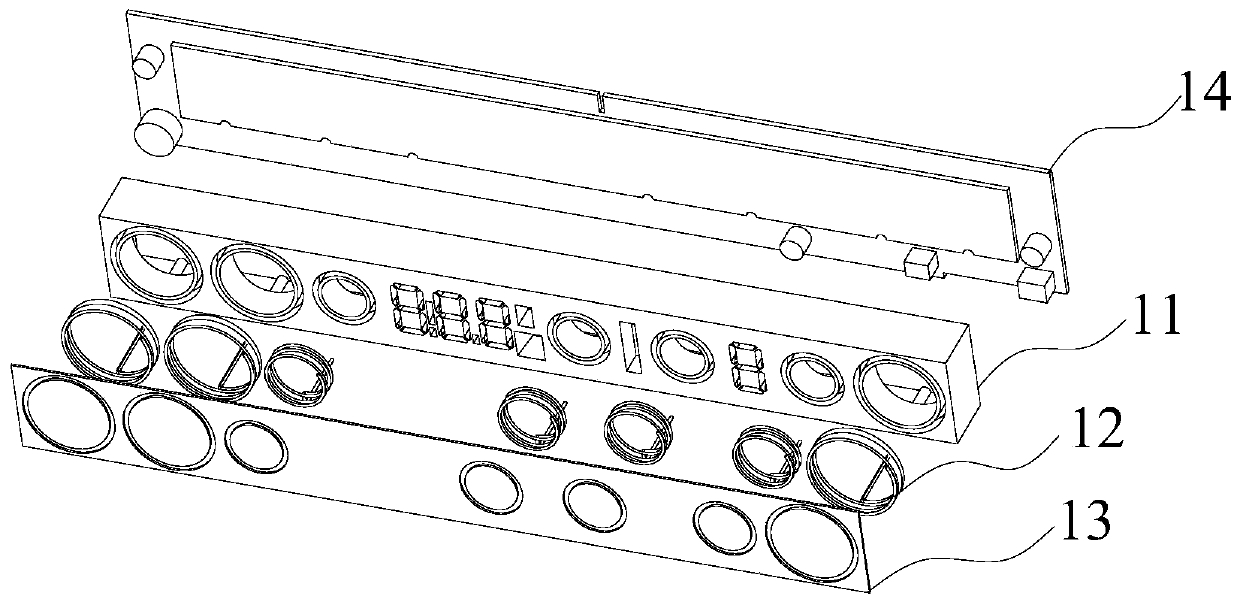

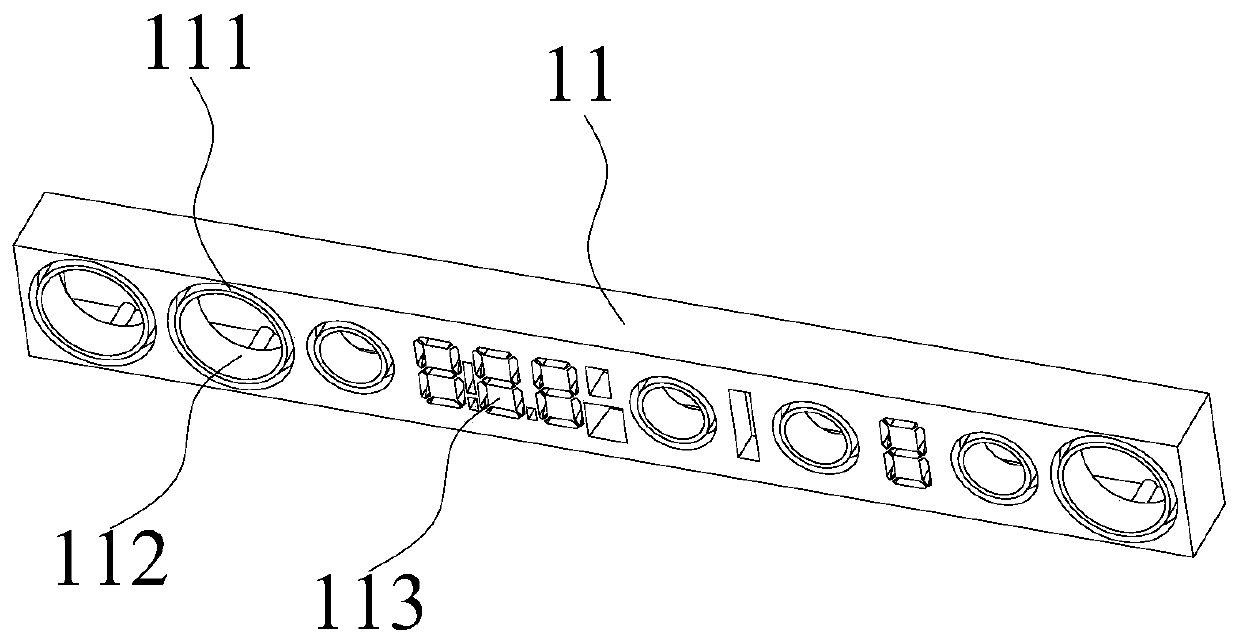

[0025] refer to figure 1 A schematic structural diagram of the manipulation display panel provided in this embodiment is shown; figure 2 An exploded view of the manipulation display panel provided in this embodiment is shown; image 3 A schematic structural diagram of the manipulation display module provided in this embodiment is shown; Figure 4 A schematic structural view of the character display film provided in this embodiment is shown.

[0026] like Figure 1-4 As shown, the present embodiment provides a control display panel, which includes a control display module 11. The surface of the control display module 11 is provided with an annular groove 111. The foot is perforated, and the touch spring 12 is arranged in the annular groove 111. The top of the touch spring 12 is higher than the surface of the control display module 11, and the solder leg of the touch spring 12 is connected to the circuit board 14 through the solder leg perforation; the control display panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com