Large-span cable-stayed bridge stay cable anchoring traction device and traction construction method thereof

The technology of a traction device and a cable-stayed anchor is applied in the construction field of cable-stayed bridges, which can solve the problems that the installation and operation requirements of large traction equipment cannot be met, the construction efficiency and construction period of the cable-stayed bridge are affected, and the operation and construction space is limited. The effect of saving anchoring box space, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

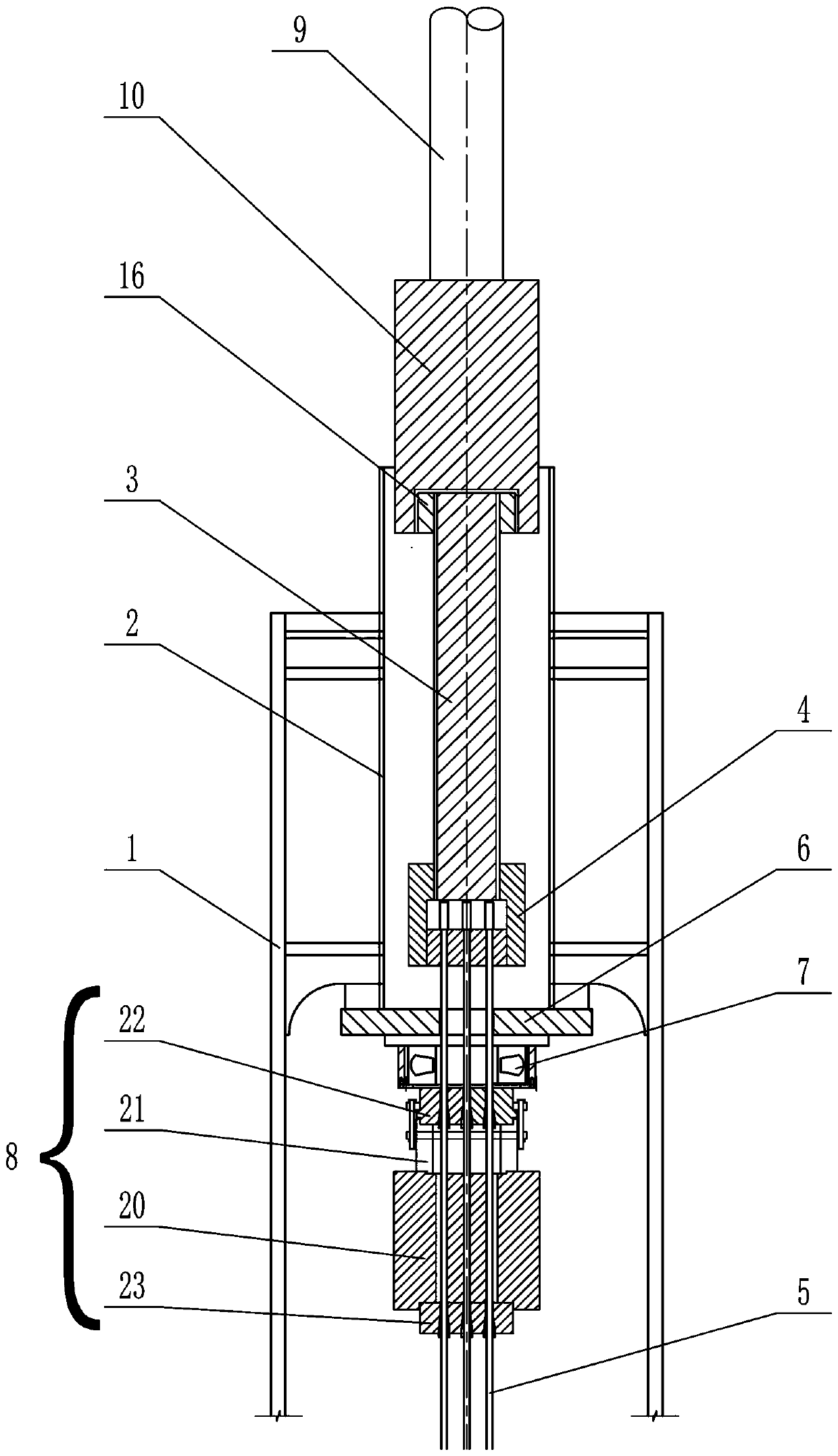

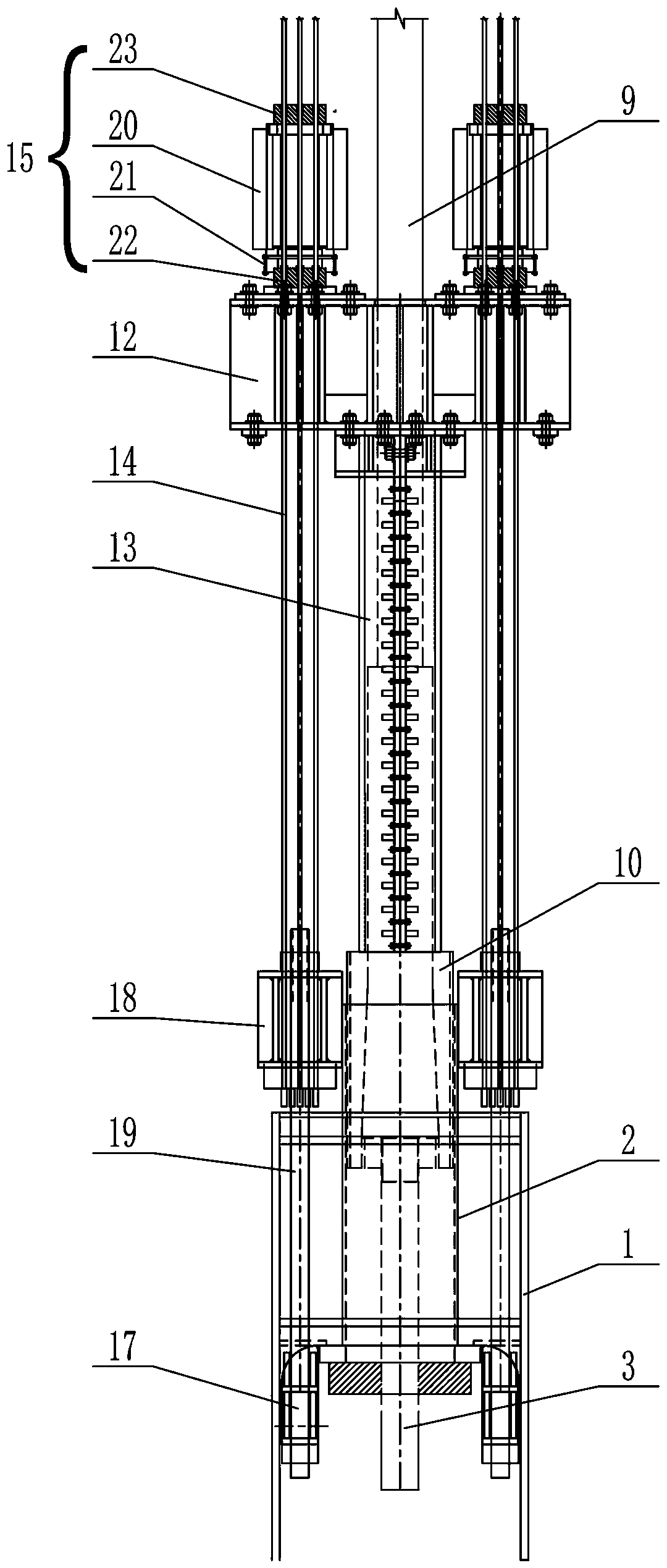

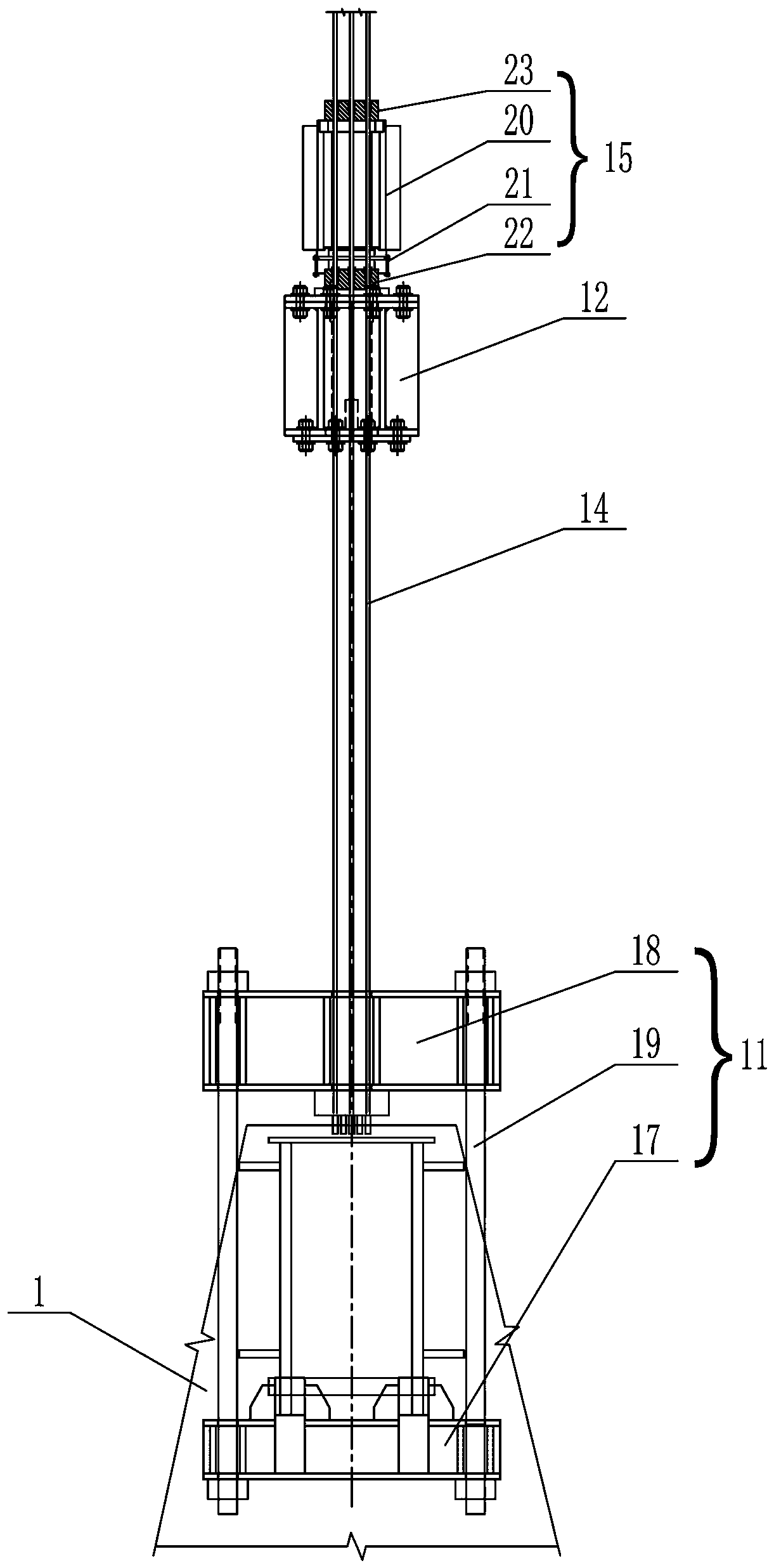

[0031] like figure 1 , figure 2 , image 3 Shown, a kind of long-span cable-stayed bridge stay cable anchoring traction device, wherein: comprise anchor box 1, cable conduit 2, traction device and back pressure device, described anchor box 1 is provided with cable conduit 2, described One end of the cable guide 2 is located in the anchor box 1, and the other end passes through the wall of the anchor box 1 and is located outside the anchor box 1. A traction device is provided in the anchor box 1, and the traction device includes a safety tension rod 3 , steel strand connector 4, traction steel strand 5, traction pressure bearing plate 6, thrust roller bearing assembly 7 and traction jack assembly 8, described insurance tension rod 3 is a screw rod, and described insurance tension rod 3 The upper end is connected to the lower end of the anchor cup 10 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com