A kind of high-strength high-toughness aluminum alloy and preparation method thereof

A high-toughness, aluminum alloy technology, applied in metal rolling and other directions, can solve problems such as failure of aluminum alloy products, strength decline, etc., and achieve the effects of improving strength and toughness, inhibiting recrystallization, and increasing diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

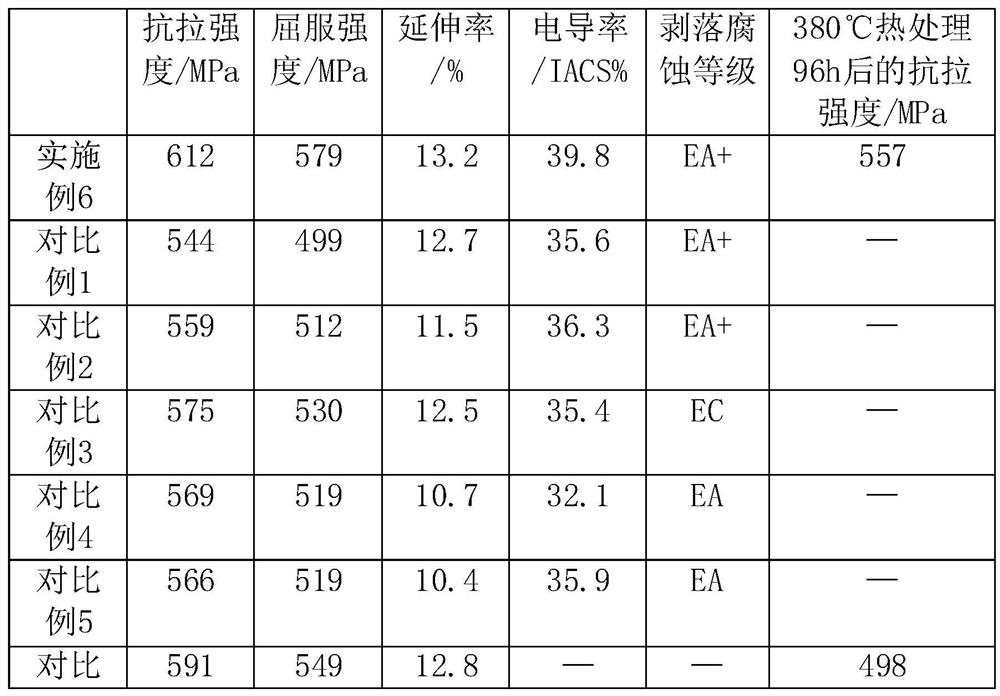

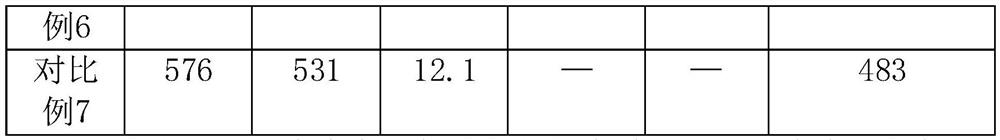

Examples

Embodiment 1

[0019] A high-strength and high-toughness aluminum alloy, its composition includes by weight percentage: Mg: 1.3%, Zn: 6.9%, Cu: 1.05%, Yb: 0.16%, Fe: 0.08%, Si: 0.11%, Zr: 0.04 %, Ti: 0.23%, Cr: 0.01%, Mn: 0.24%, B: 0.14%, Li: 0.21%, Ag: 0.28%, and the balance is Al.

[0020] The present invention also proposes a method for preparing the high-strength and high-toughness aluminum alloy, comprising the following steps:

[0021] S1. Weigh magnesium ingots, zinc ingots, aluminum-copper master alloys, Al-Yb master alloys, aluminum-iron master alloys, metal silicon, aluminum-zirconium master alloys, aluminum-titanium master alloys, aluminum-chromium master alloys, manganese ingots, aluminum Boron master alloys, aluminum-lithium master alloys, aluminum ingots and pure silver; metal silicon, aluminum ingots, magnesium ingots, zinc ingots and manganese ingots are added to the smelting furnace, melted at 770°C for 25 minutes, then the remaining raw materials are added, melted and refin...

Embodiment 2

[0024] A high-strength and high-toughness aluminum alloy, its composition includes by weight percentage: Mg: 1.5%, Zn: 7.1%, Cu: 2%, Sc: 0.01%, Er: 0.07%, Fe: 0.08%, Si: 0.15 %, Zr: 0.12%, Ti: 0.09%, Cr: 0.03%, Mn: 0.1%, B: 0.07%, Li: 0.27%, Ag: 0.3%, and the balance is Al.

[0025] The present invention also proposes a method for preparing the high-strength and high-toughness aluminum alloy, comprising the following steps:

[0026] S1. Weigh magnesium ingots, zinc ingots, aluminum-copper master alloys, Al-Sc master alloys, Al-Er master alloys, aluminum-iron master alloys, metal silicon, aluminum-zirconium master alloys, aluminum-titanium master alloys, and aluminum-chromium master alloys according to the ratio Alloy, manganese ingot, aluminum-boron master alloy, aluminum-lithium master alloy, aluminum ingot and pure silver; metal silicon, aluminum ingot, magnesium ingot, zinc ingot and manganese ingot are put into the melting furnace, melted at 750°C for 55min, and then added...

Embodiment 3

[0029] A high-strength and high-toughness aluminum alloy, its composition includes by weight percentage: Mg: 1.99%, Zn: 6.18%, Cu: 1.1%, RE: 0.07%, Fe: 0.15%, Si: 0.18%, Zr: 0.09 %, Ti: 0.01%, Cr: 0.02%, Mn: 0.12%, B: 0.07%, Li: 0.11%, Ag: 0.42%, and the balance is Al; wherein, RE is a mixture of Y, Ce, La, and The weight ratio of Y, Ce, and La is 1:3:3.

[0030] The present invention also proposes a method for preparing the high-strength and high-toughness aluminum alloy, comprising the following steps:

[0031] S1. Weigh magnesium ingots, zinc ingots, aluminum-copper master alloys, Al-RE master alloys, aluminum-iron master alloys, metal silicon, aluminum-zirconium master alloys, aluminum-titanium master alloys, aluminum-chromium master alloys, manganese ingots, aluminum Boron master alloys, aluminum-lithium master alloys, aluminum ingots and pure silver; metal silicon, aluminum ingots, magnesium ingots, zinc ingots and manganese ingots are added to the melting furnace, melted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com