Vertical sludge cleaning treatment machine for river channel dredging

A sludge and river technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the impact on the growth of plants or farmed animals, and is not easy to treat and reuse sludge. It is not easy to apply force and pressure to achieve the effect of improving the degree of formability, facilitating forming and reducing the degree of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

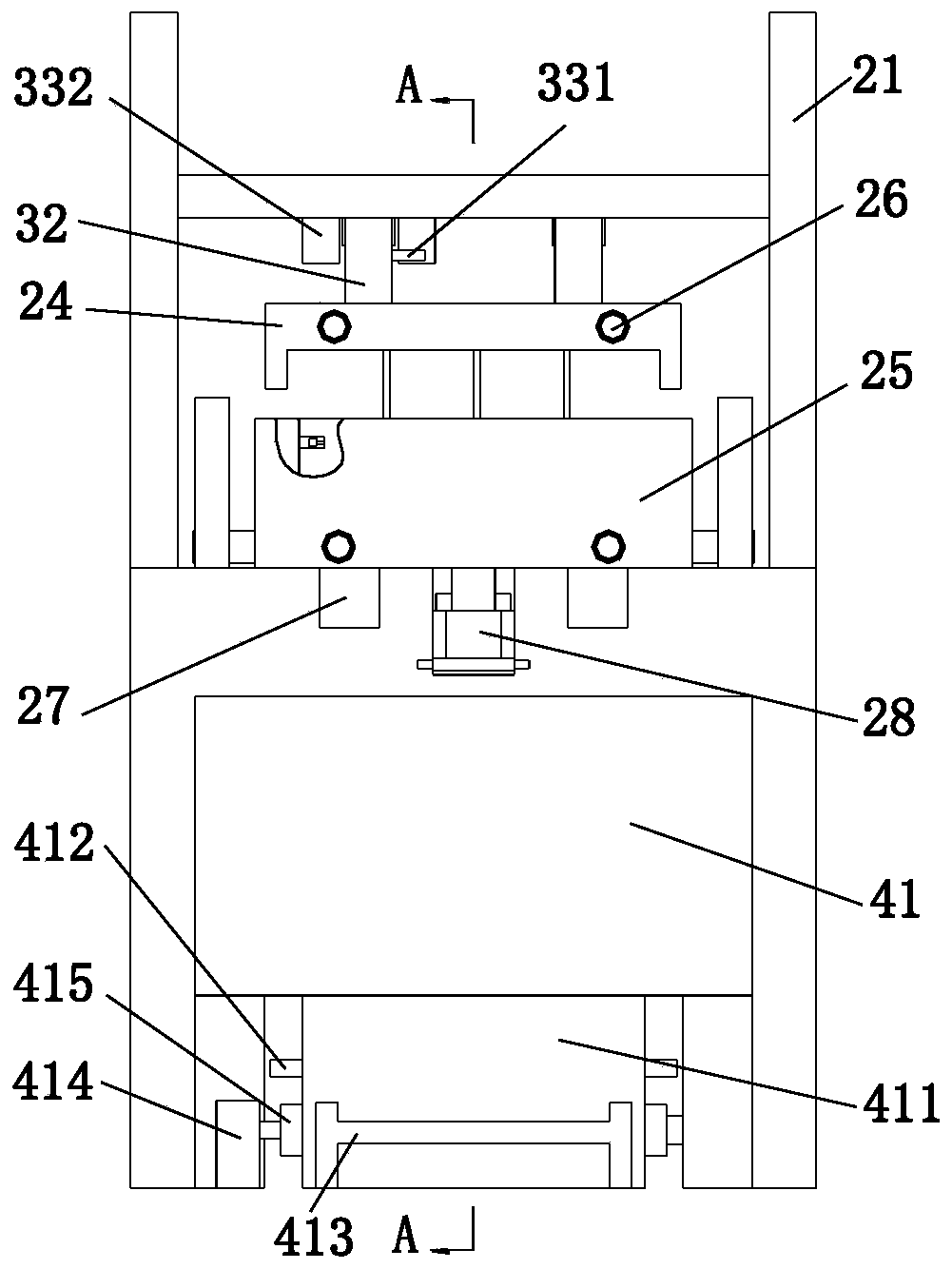

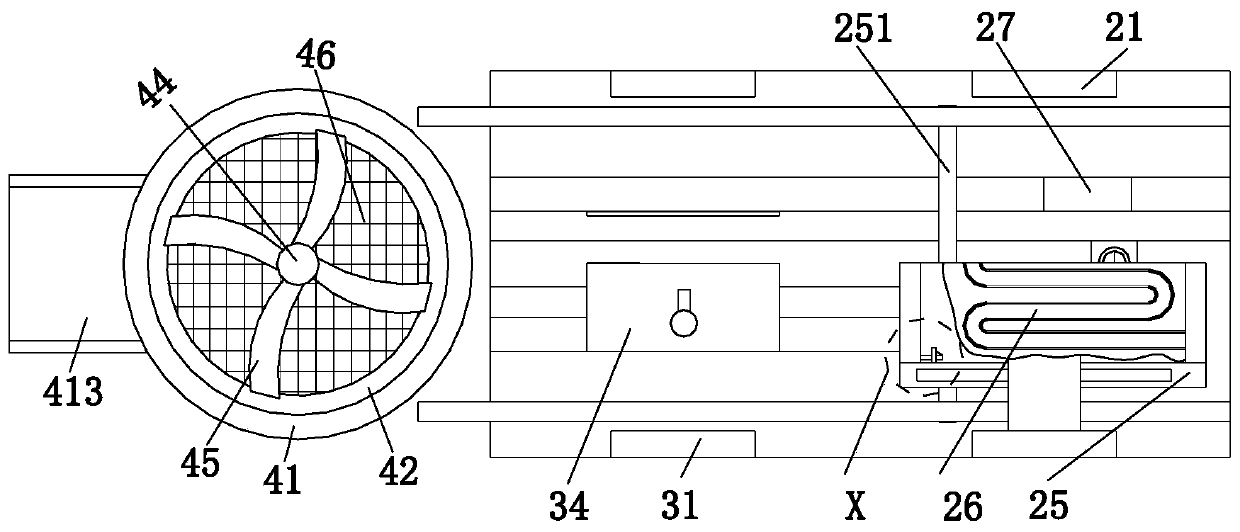

[0029] like Figure 1 to Figure 6 As shown, a river channel dredging upright sludge cleaning and processing machine includes a workbench 1, a drying device 2, a block cutting device 3 and a crushing device 4. The right end of the upper end surface of the workbench 1 is installed with a The drying device 2 is provided with a block cutting device 3 on the left side of the drying device 2, and the block cutting device 3 is connected with the upper surface of the workbench 1 through a sliding fit, and the left side of the workbench 1 is provided with a crushing device 4.

[0030]The drying device 2 includes a slide rail frame 21, a No. 1 electric skateboard 22, a connecting shaft 23, a U-shaped cover plate 24, a mud bucket 25, a pipeline 26, a No. 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com